It’s worth noting that this test is simply that: a test. It’s meant to simulate real world conditions and guarantee that the part meets generally accepted standards. But it simulates those conditions only generally; manufacturers of these kinds of parts will often have their own in-house spec that to tune the characteristics they optimize for. But in general, a designer needs to choose a test, and then optimize his design such that the part fails just beyond the test’s requirements. If I trust the ISO spec implicitly then it stands to reason that I should remove more material from the part; after all, it passed the test with a wide margin.

Regardless, my part could be further optimized. What I’ve done to date was prove a basic concept: That metal powder bed fusion can be used to make thin walled bicycle parts. Which, to be honest, isn’t a particularly surprising result; after all, metal powder bed fusion has been used by others to create all kinds of bike parts, including both road and mountain frames.

The question is: Can I make it commercially viable?

Practical matters

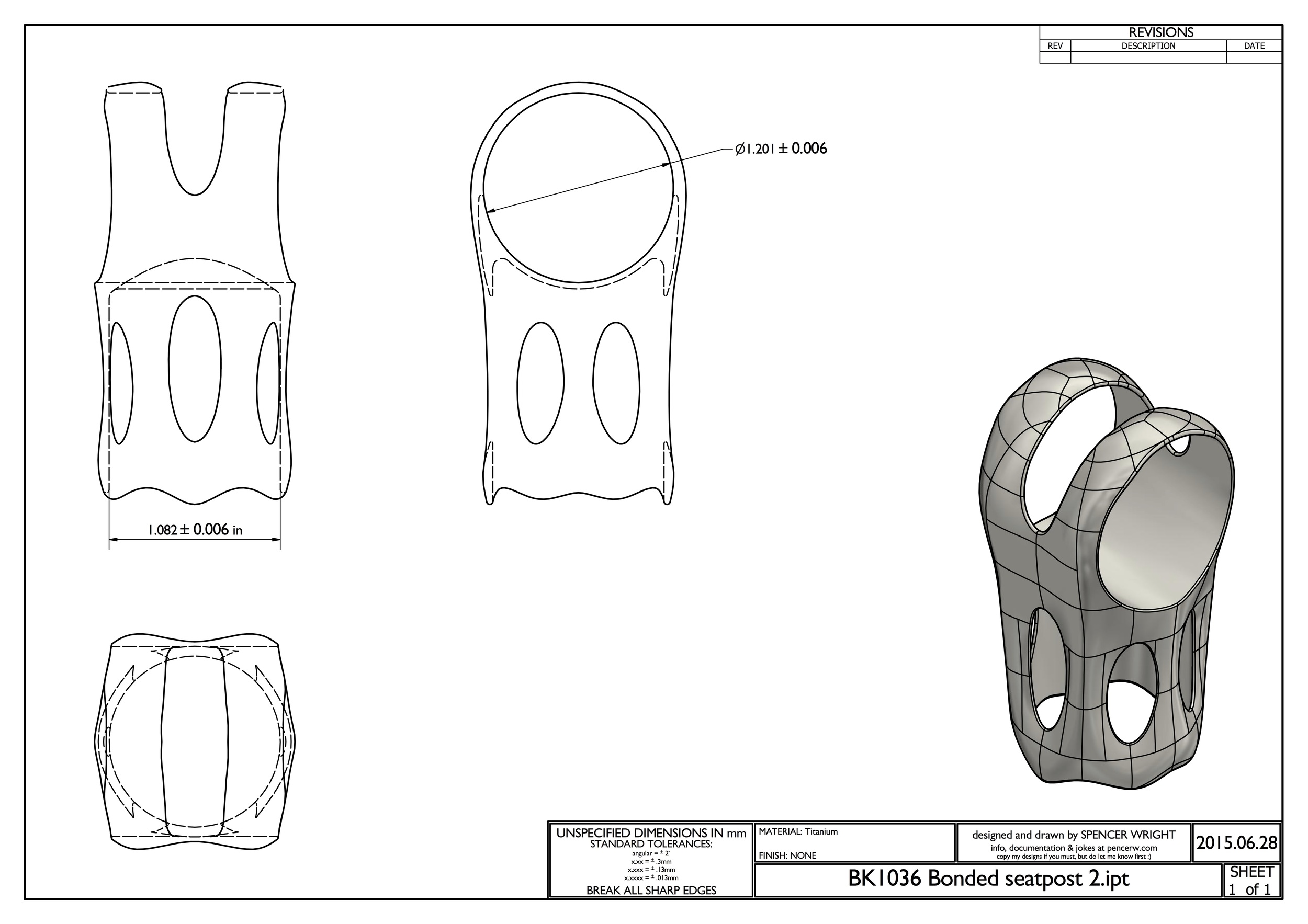

With the current design and an order quantity of 10 pieces, the as-printed parts cost about $500 to make. Meanwhile, the most expensive commercially available seatmast topper I’m aware of (made by No22) costs $300, and the fanciest seatpost I’ve ever seen (made by AX Lightness) was under $600.

Now, there are a number of interesting things to note here. First, I’m able to buy in fairly low quantities. It’s not unreasonable for me to purchase parts in batches of 10, which is about as low as any non-stock commercial product in the world— and much lower than most products that involve forging, casting or CNC machining. If I can sell my part at a high end price point, then it wouldn’t take much cost reduction before I’ve got a reasonable margin — even with a strikingly low order volume. And there are a number of ways that I can reduce cost on this part:

- Even keeping the part’s design the same, I can reduce the cost by 25–40% by doubling the layer thickness. This will result in a rougher surface finish, but it’s possible that the difference will be acceptable.

- A significant amount of time and effort can be saved by redesigning the underlying model so that the inner diameters need very little — or even zero — post processing. It’s unclear exactly how much work this will take, but it could reduce the price significantly.

- Moreover, the entire part can be redesigned in order to reduce both the end mass *and* the amount of support structures necessary. Both of these have a big effect on price, though it will be time consuming to find an optimal design.

All of this assumes that I stick with a laser powered process. Electron beam melting (which I’ve been experimenting with) might reduce cost further, though the design constraints there are quite different.

It’s also possible that while this part isn’t the absolute best application for additive manufacturing, there’s another place on high end bicycles where additive works better. This is key: The cost of this part is in the right order of magnitude as my goal. Any number of small changes — whether to the machine’s build parameters, the design, or the underlying cost of the technology — could easily put the numbers in my favor.

Industry observations

As I hope you would expect by now, a few things have jumped out to me in this past few months of work — some relating to longer term questions I have about the industry.

Manufacturing design

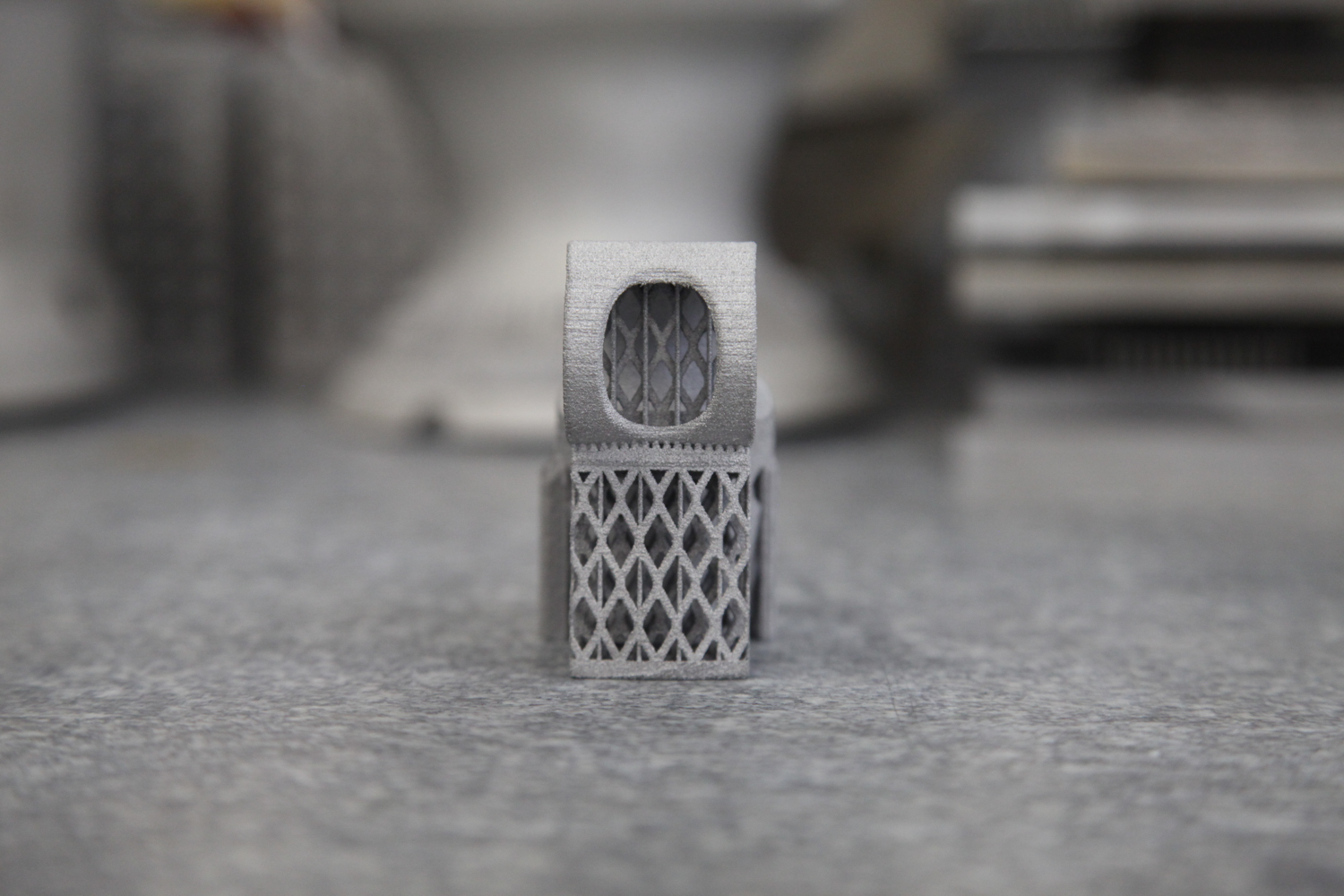

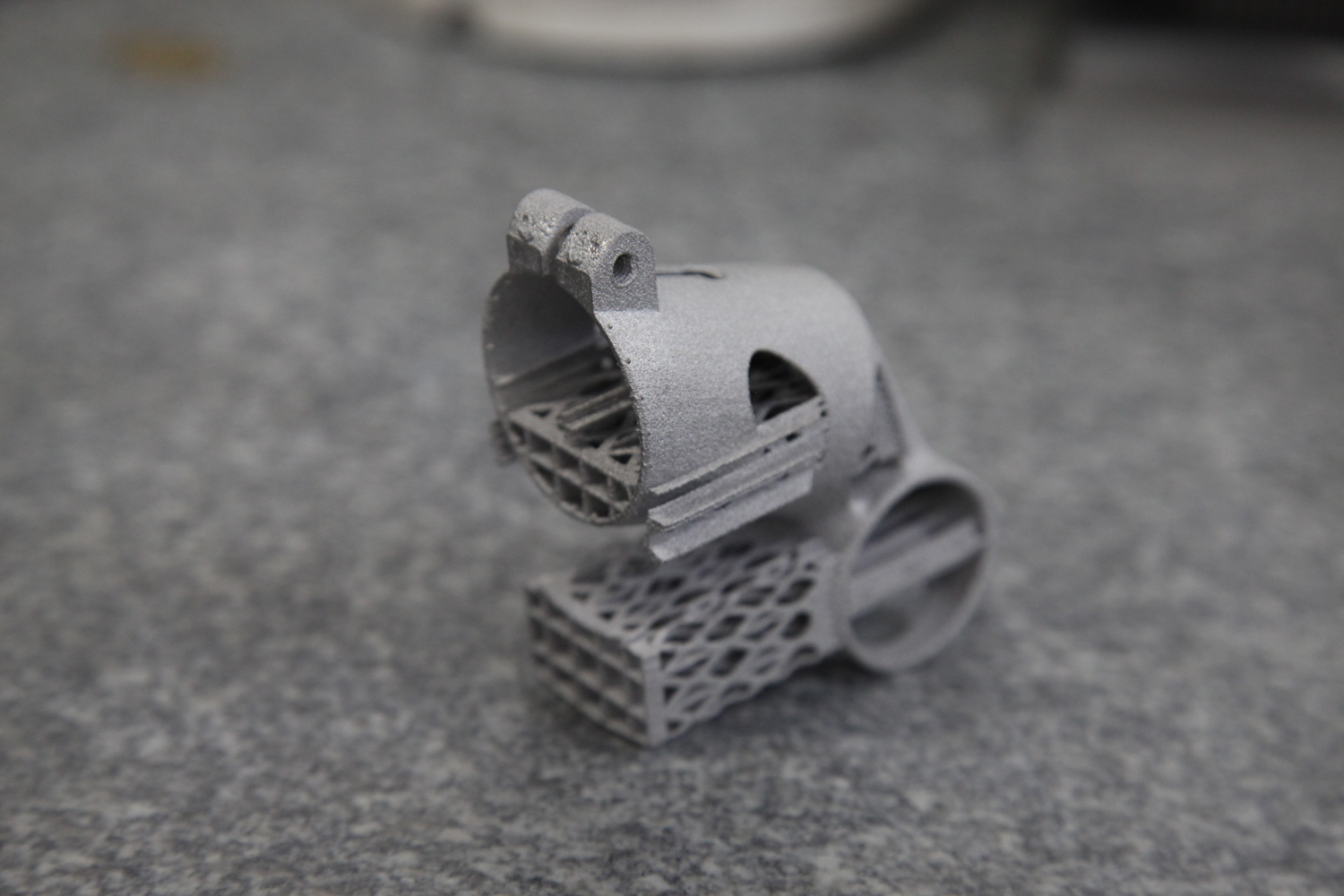

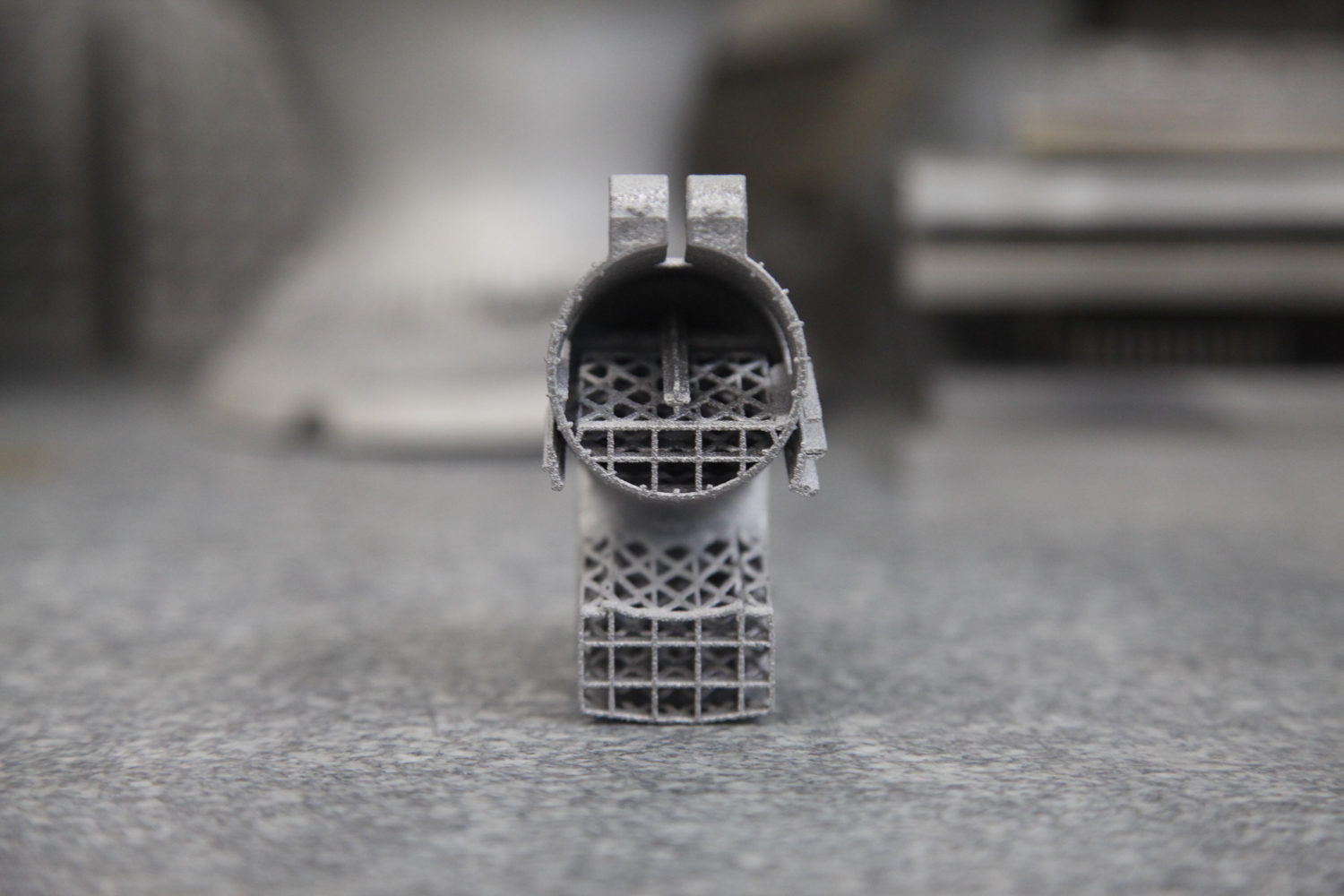

As a designer, having more — and earlier — access to support structure generation software is incredibly helpful. Today, countless design decisions are made on little more than a hunch; it’s not until much later that the ramifications of those decisions become evident. This leads to an inefficient design-for-manufacturing process, where it’s difficult for product designers and manufacturing engineers to communicate all of the nuance needed. Until professional grade design software (and here I’m looking at Autodesk, Dassault, Siemens, and PTC) allows these implications to be understood early on, this will be a big problem. In other words, I should be able to set build orientation and design support structures directly in my CAD modeling environment.

Documentation

The designs that are loaded onto a metal 3D printer are often very different from the finished part, whether due to the addition of stock material to be removed subsequently (like my female threads), or the support structures necessary to hold the part on the build platform. But today’s modeling software generally only shows one state for each 3D model; those intermediate, near net shapes aren’t linked to the end design. This makes the design for manufacturing process even more disjointed and awkward, as it means that I’m never working on the same design documents as my manufacturing partner is. This communication structure is bound (cf. Conway’s Law) to be replicated in the end product, and the result is bad. To fix it, we need a new class of software that blends CAD (computer aided design) and CAM (computer aided manufacturing), allowing designers to understand a part’s production cycle with perfect clarity.

True design optimization

In the work I’ve described so far, I’ve relied exclusively on conventional volumetric and NURBS modeling techniques. But a new wave of design tools is out there — topology optimization and lattice generation, for instance — and they promise to create designs directly from functional requirements. Presumably these techniques would be just as applicable to my part as they are to the applications they’re already used on (mainly aerospace, biomedical, and other high tech applications). I’ve begun to explore this space, but the fact of the matter is that I’m not aware of a single consumer product today that was designed with these tools. My hope is that they both remove weight and make the part more visually appealing, but it could take a lot of work and some expensive (and experimental) software to find whether I’m correct.

Blatant editorializing: Gongkai for industrial additive manufacturing

Today, the viability of additive processes is totally opaque, producing a chilling effect on the creativity of both designers, service bureaus, and machine manufacturers. It’s my strong belief that that will only change by better understanding the efficiencies (and inefficiencies) of the additive manufacturing toolchain, and through my own work I hope to do just that.

In a series (one, two) of recent blog posts, Bunnie Huang describes the way that Chinese electronics manufacturers have been able to drastically decrease the cost of consumer electronics. To me, they provide an example for how additive manufacturing could advance much more quickly:

My most striking impression was that Chinese entrepreneurs had relatively unfettered access to cutting-edge technology, enabling start-ups to innovate while bootstrapping. Meanwhile, Western entrepreneurs often find themselves trapped in a spiderweb of IP frameworks, spending more money on lawyers than on tooling. Further investigation taught me that the Chinese have a parallel system of traditions and ethics around sharing IP, which lead me to coin the term “gongkai”… this copying isn’t a one-way flow of value, as it would be in the case of copied movies or music. Rather, these documents are the knowledge base needed to build a phone using the copyright owner’s chips, and as such, this sharing of documents helps to promote the sales of their chips. There is ultimately, if you will, a quid-pro-quo between the copyright holders and the copiers.

It would be an understatement to say that industrial additive manufacturing hasn’t adopted gongkai. Today, trade secrets & patents are the name of the game; the access I’ve been permitted (by Layerwise, DRT Medical-Morris, and countless other friends across the industry) is rarely afforded to others. It’s my feeling that this is bad, both for the technology as a whole and for the long term interest of individual players within it.

For instance: Anyone with experience could, given a part geometry and its build orientation, surmise more or less what the support structures will look like. If you have a physical part in hand, it’s even easier to reverse engineer; a part’s layer boundaries reveal its build orientation, and even with careful cleanup it’s generally possible to tell which surfaces have had support structures removed from them. In short, manufacturing forensics is, with enough experience and care, fairly reliable. And yet orientation and support structure setups are almost always treated as closely guarded secrets.

With so much uncertainty in industrial additive manufacturing today, firms are caught in something of a prisoner’s dilemma; their protective IP strategies prevent the industry from moving forward in the way that everyone ultimately wants it to.

All around the world, intelligent, hardworking people trying to solve the most basic problems in additive manufacturing. Everyone in the industry knows what these are, and all of the major players are fighting tooth and nail to solve them first. And though it seems a long way off, I think most of them genuinely believe that they’ll see fully automated orientation & support structure generation within the next decade or two.

But today, the process of printing a part is decidedly hands-on; expertise is critical. “The people who are good at this stuff are good at it because they’ve been doing it for eight years,” one industry veteran told me recently. For sure, this industry is full of valuable intellectual property. But in most cases, *craftsmanship* is central to most firms’ bottom lines — and it is protected at all expense.

I believe that industrial additive manufacturing needs far, far more knowledge sharing. We need an environment closer to the one that Bunnie describes:

We need “a ‘network’ view of IP and ownership: the far-sight necessary to create good ideas and innovations is attained by standing on the shoulders of others, and as such there [should be] a network of people who trade these ideas as favors among each other.”

In the coming moths, I’m looking forward to working on just that.

This post is just one in a series, and I remain convinced of what I’m working towards. With any luck — and more open collaboration with intelligent, committed people in the industry — I’ll have more to report soon :)

Thanks to

First, thanks to Martijn Vanloffelt and Tom De Bruyne, of Layerwise, for both their hard work and their willingness to help me understand how they work.

Second, thanks to Marcus Schröder, of EFBE, for both his hard work and the enthusiasm he had for testing my part — and discussing at length the testing & engineering cycle he sees in the industry today.

Thanks also to Dave Bartosik, of DRT Medical-Morris, and Dustin Lindley, of UCRI. Their continued technical help has been an incredible asset, without which I may never have begun this project.

Thanks also to Clay Parker Jones and Bradley Rothenberg for reading early versions of this piece.