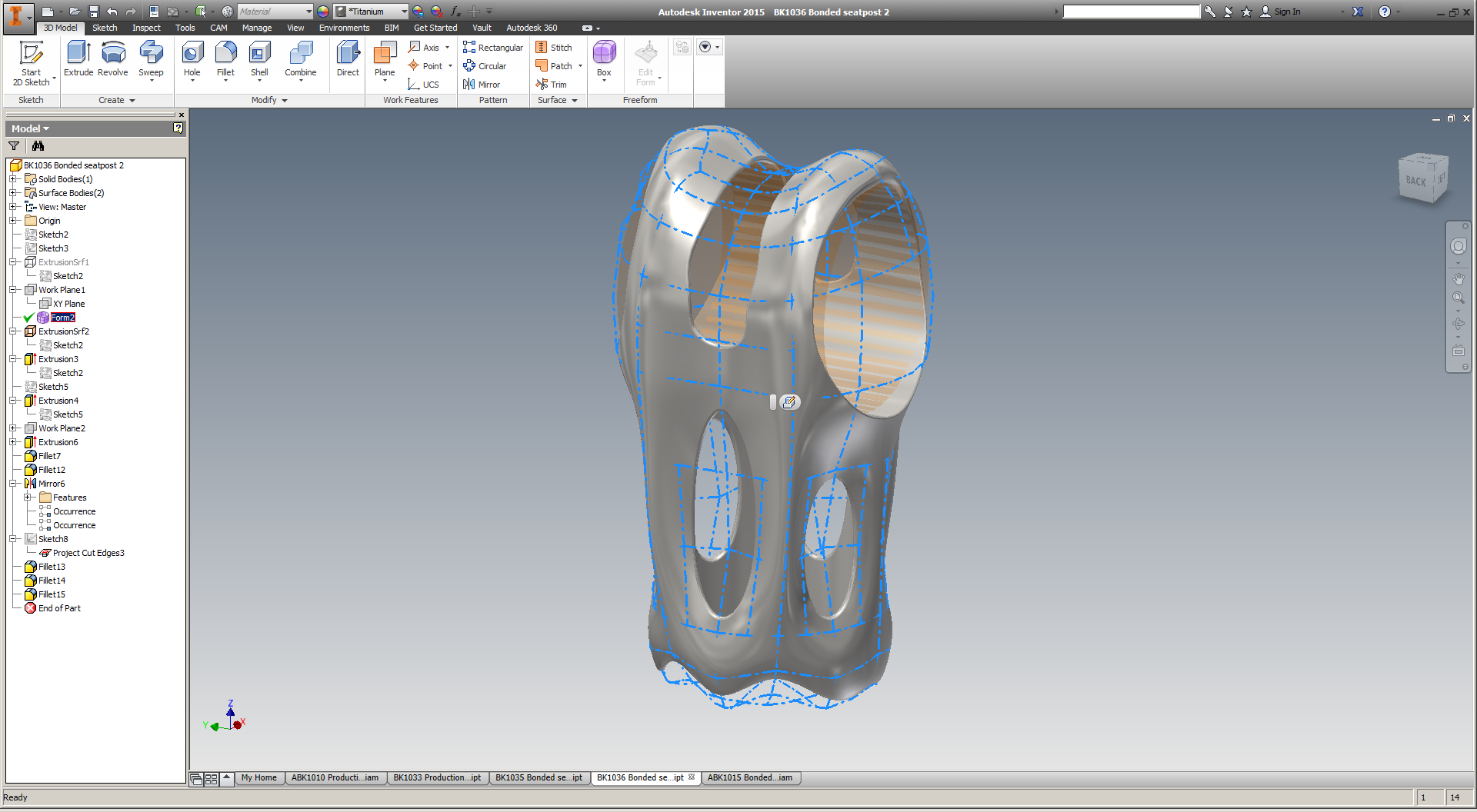

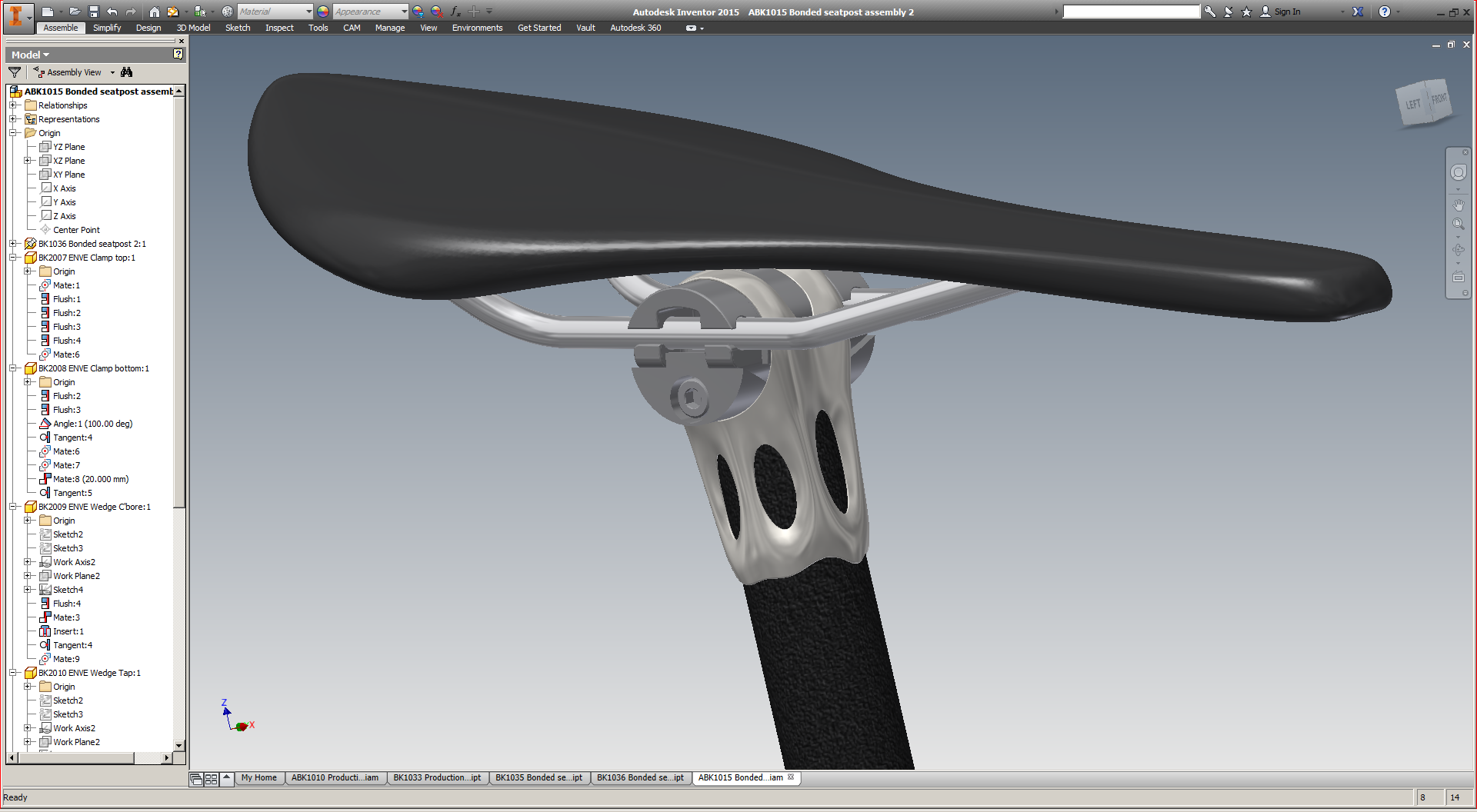

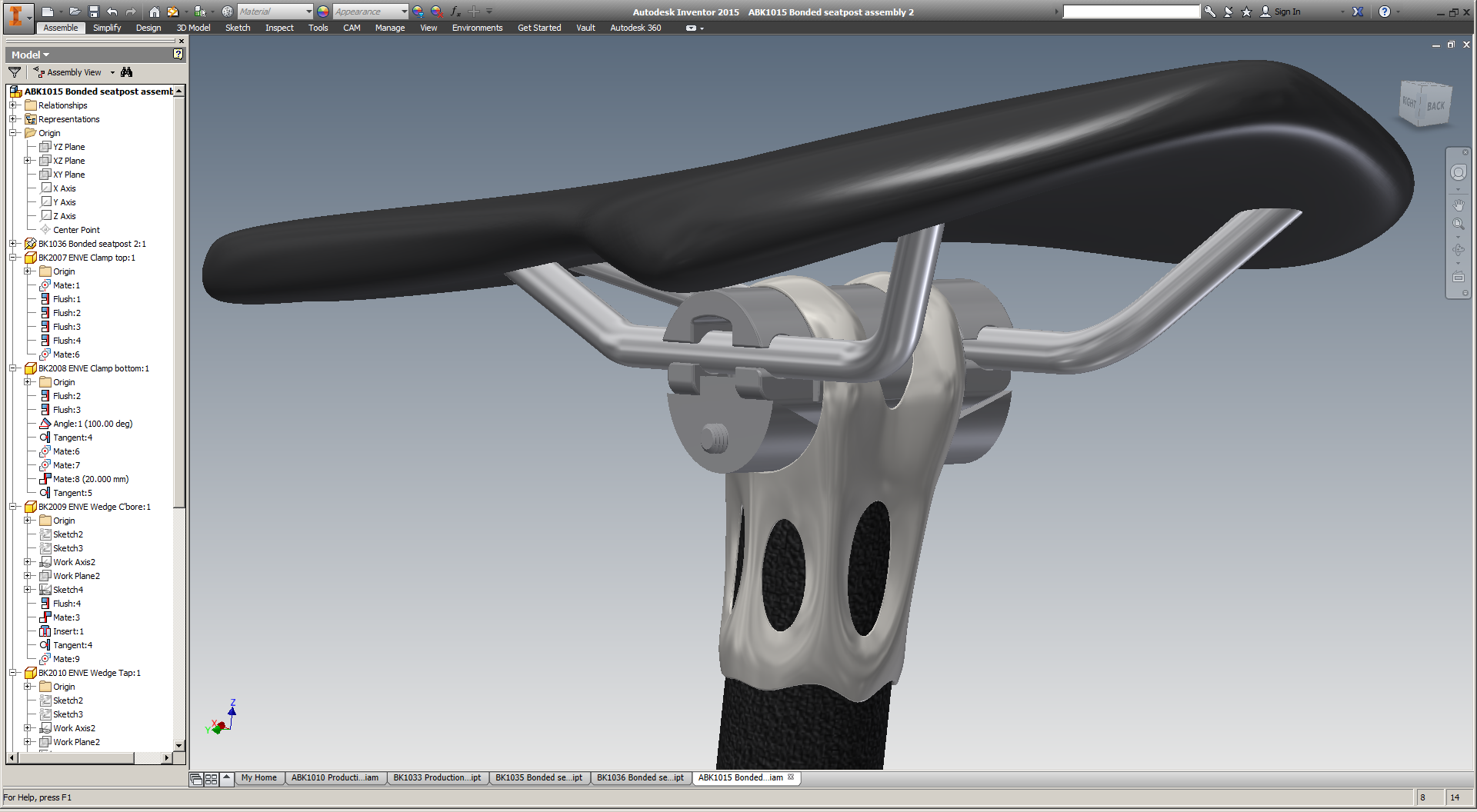

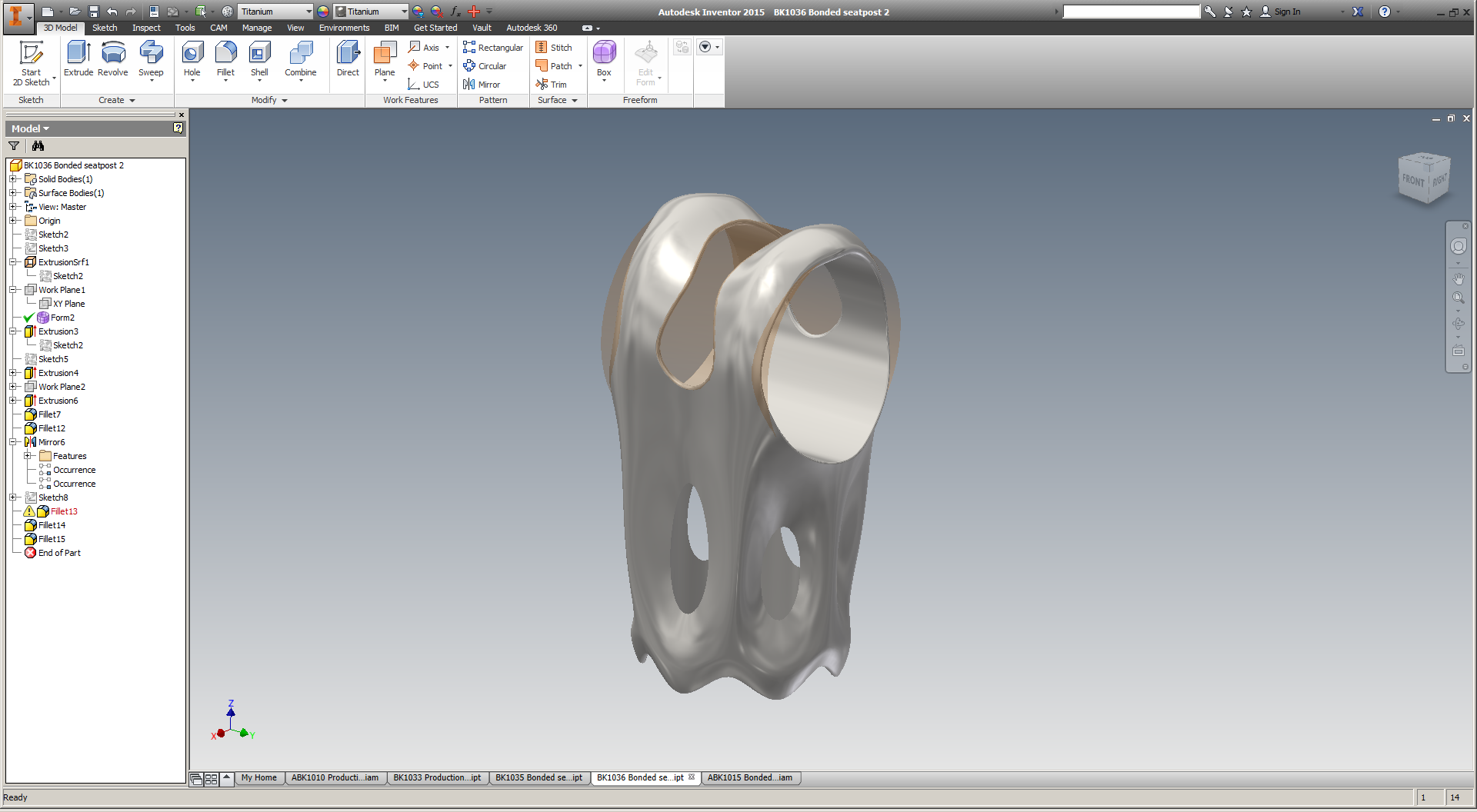

As my seatmast topper has been moving towards destructive testing, I've been playing with a new seatpost design. This part would probably be EBM'd, and then bonded (with 3M DP420 or similar epoxy) to 27.2mm carbon fiber seatpost stock. I suspect that this design will be a bit more economical, and would work on a wider range of bicycles - including my own.

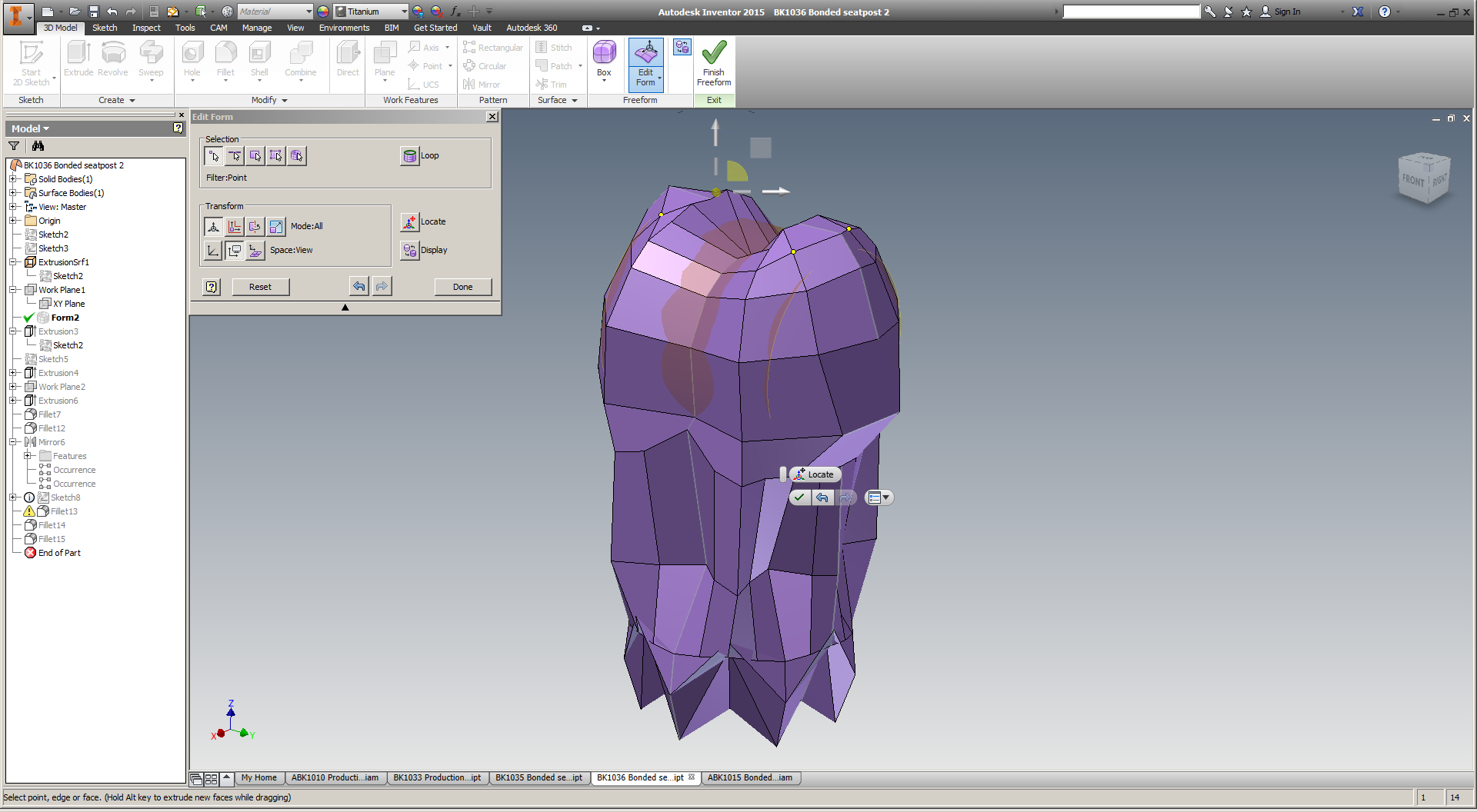

I've been pursuing the redesign in a few ways. First, I've been working with a few NYC folks to develop designs that incorporate either topology optimization, or lattice structures, or possibly both (more on this soon). Second, I got a trial license of SolidThinking Inspire, and have been using that to reduce mass within a design space that I set up in Inventor. And third, I took a crack at designing the part from scratch with T-splines in Inventor, which I *really* enjoy.

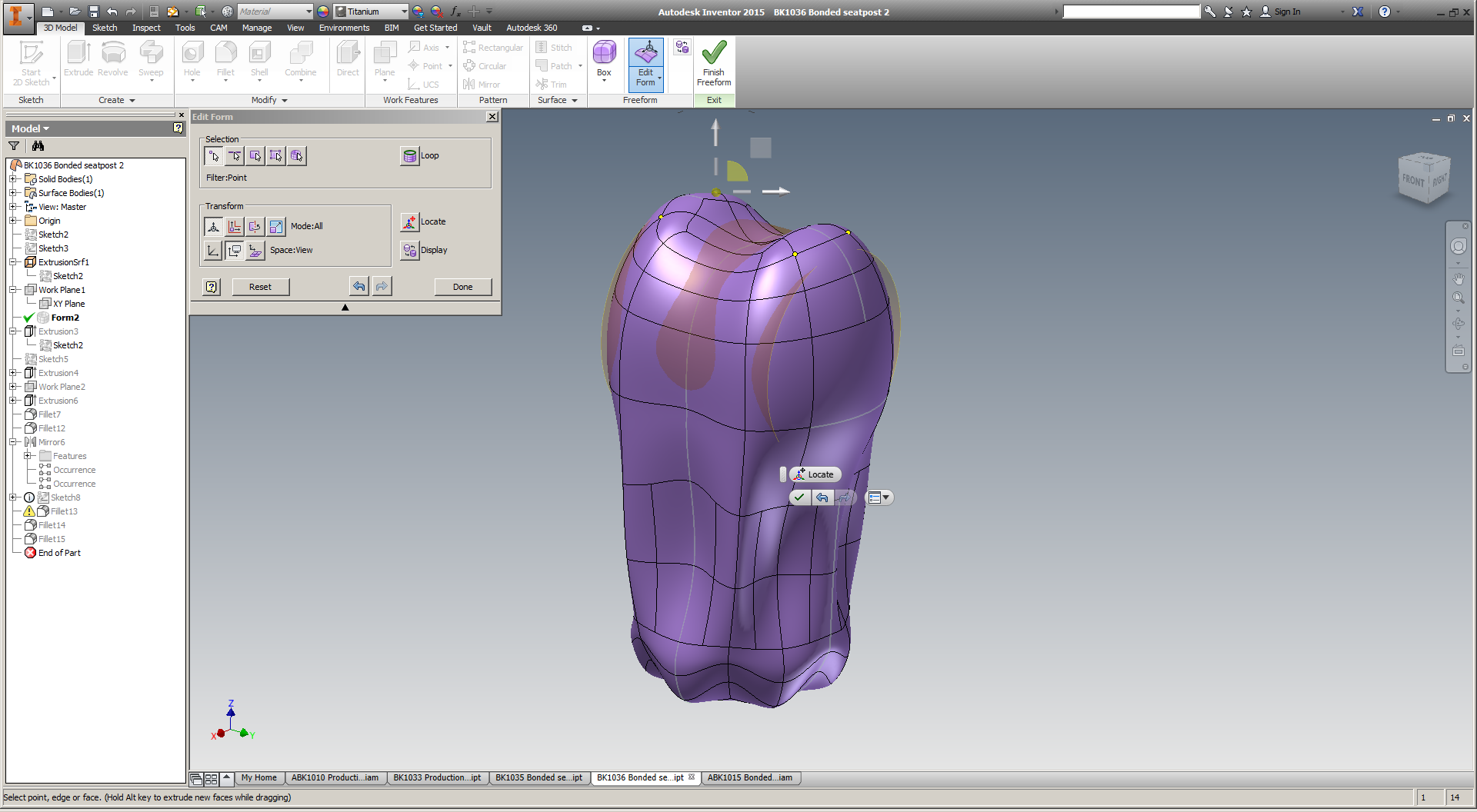

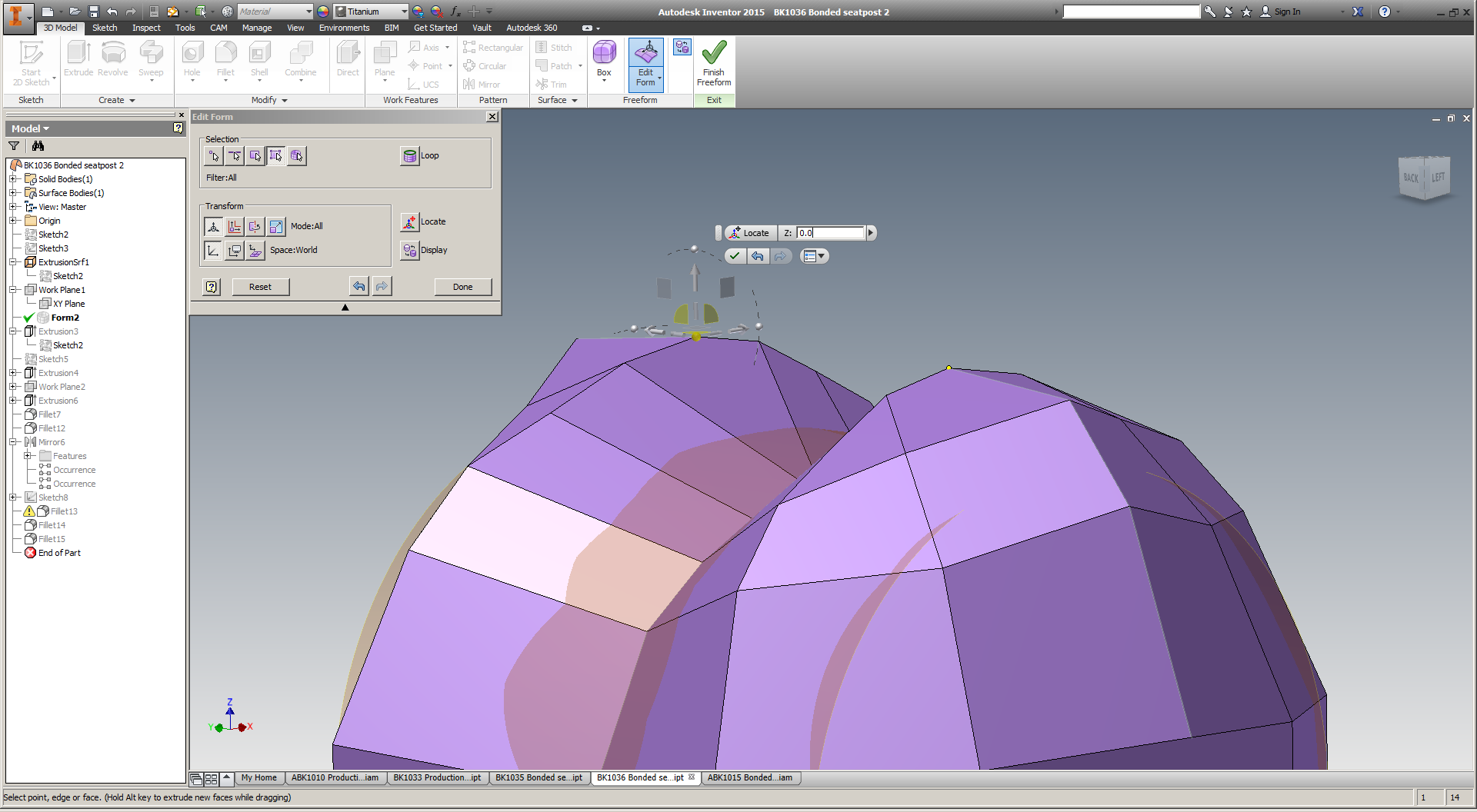

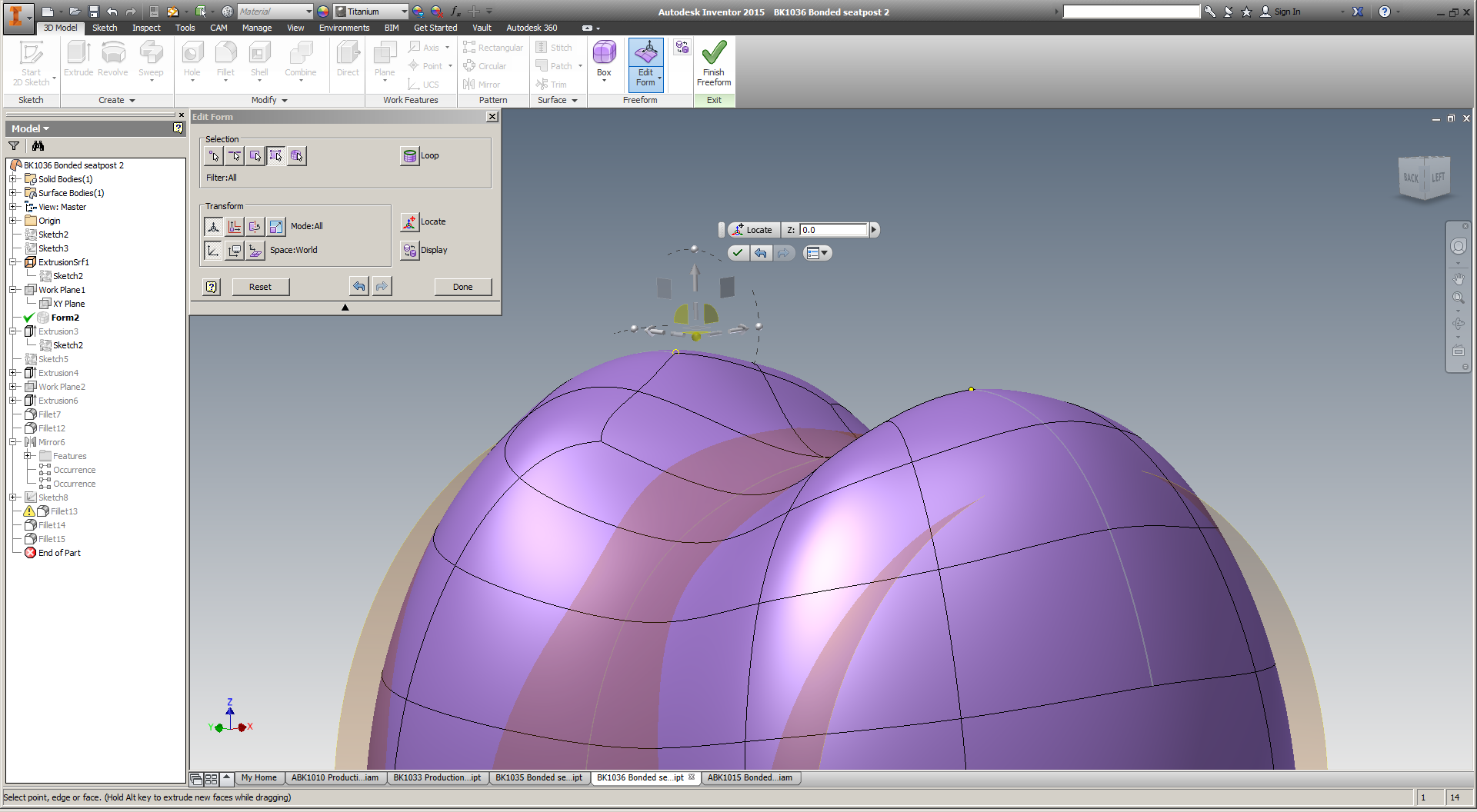

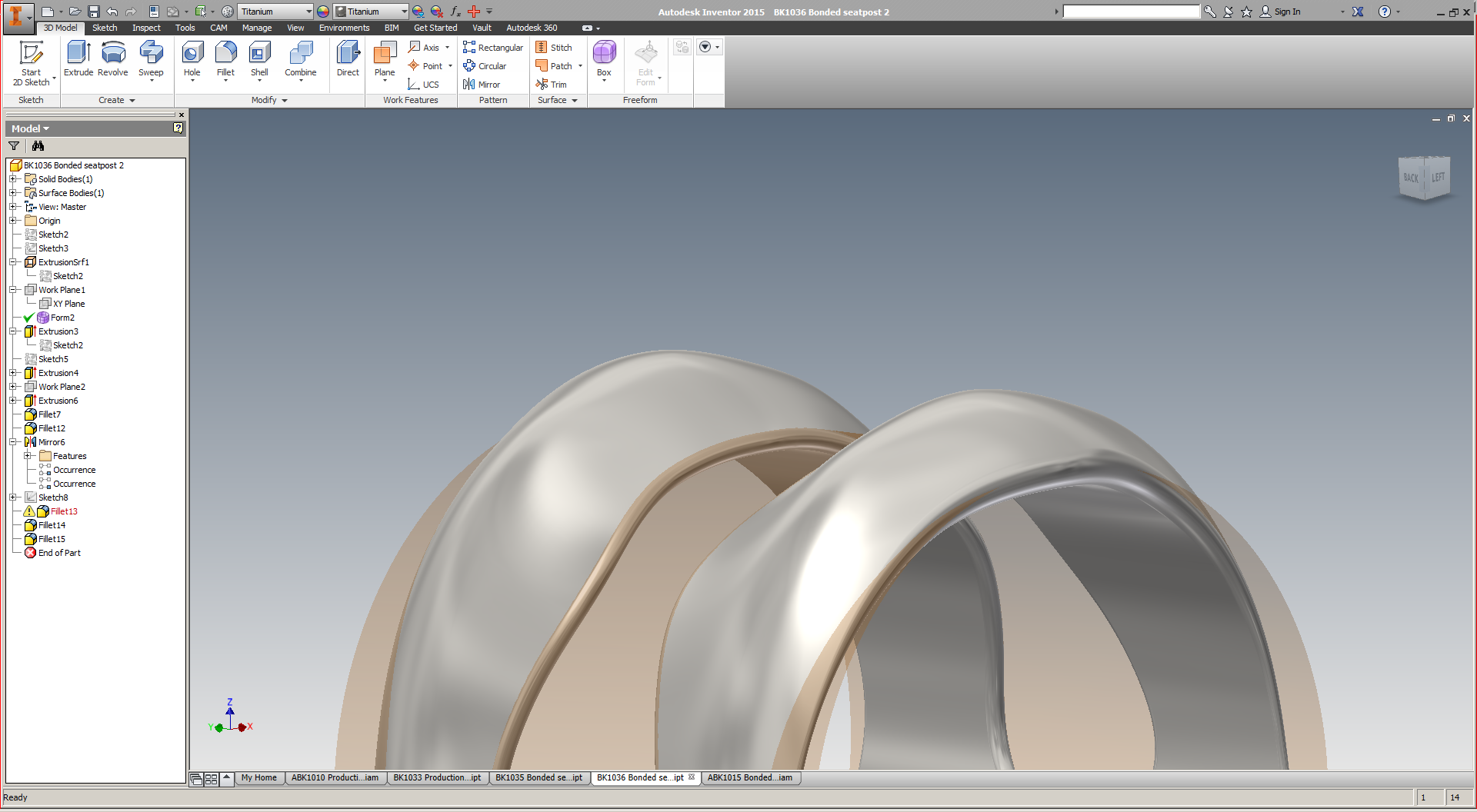

T-splines are a totally different way of approaching design, and they allow you to manually create organic looking structures. Once I've created the organic shape, I apply a bunch of features to it in Inventor's solid environment - allowing me to blend precise mechanical aspects within an otherwise fluid shape.

Ultimately, I'm optimistic that topology optimization & lattices will offer a less labor intensive workflow. T-splines are *awesome,* but editing them is a bit of an art, and I'd like to be able to redesign the part quickly to accommodate different saddle offsets, strength limits, seatpost diameters, etc.

Expect more progress soon :)