The thing is, VHB tape is awesome. It's an industrial strength, double-sided foam adhesive, capable of creating *really* strong bonds between basically anything that you'd want to stick together. I've used it in a few contexts, and encourage anyone who takes hardware projects seriously to keep VHB tape in mind as an alternative to welding, bolting, or gluing parts together.

I first became aware of VHB tape when building bikes, and used it (as part of 3M's "mushroom head" tape, which is the same stuff that EZPass uses to stick sensors to your windshield) to create a modular front rack system that didn't require bungee cords. Later, when I was working on robot doors, I seriously considered using VHB tape to bond mahogany cladding to the doors' aluminum frames; we eventually decided on structural adhesives, and dealt with a slew of issues resulting from differences in thermal expansion rates.

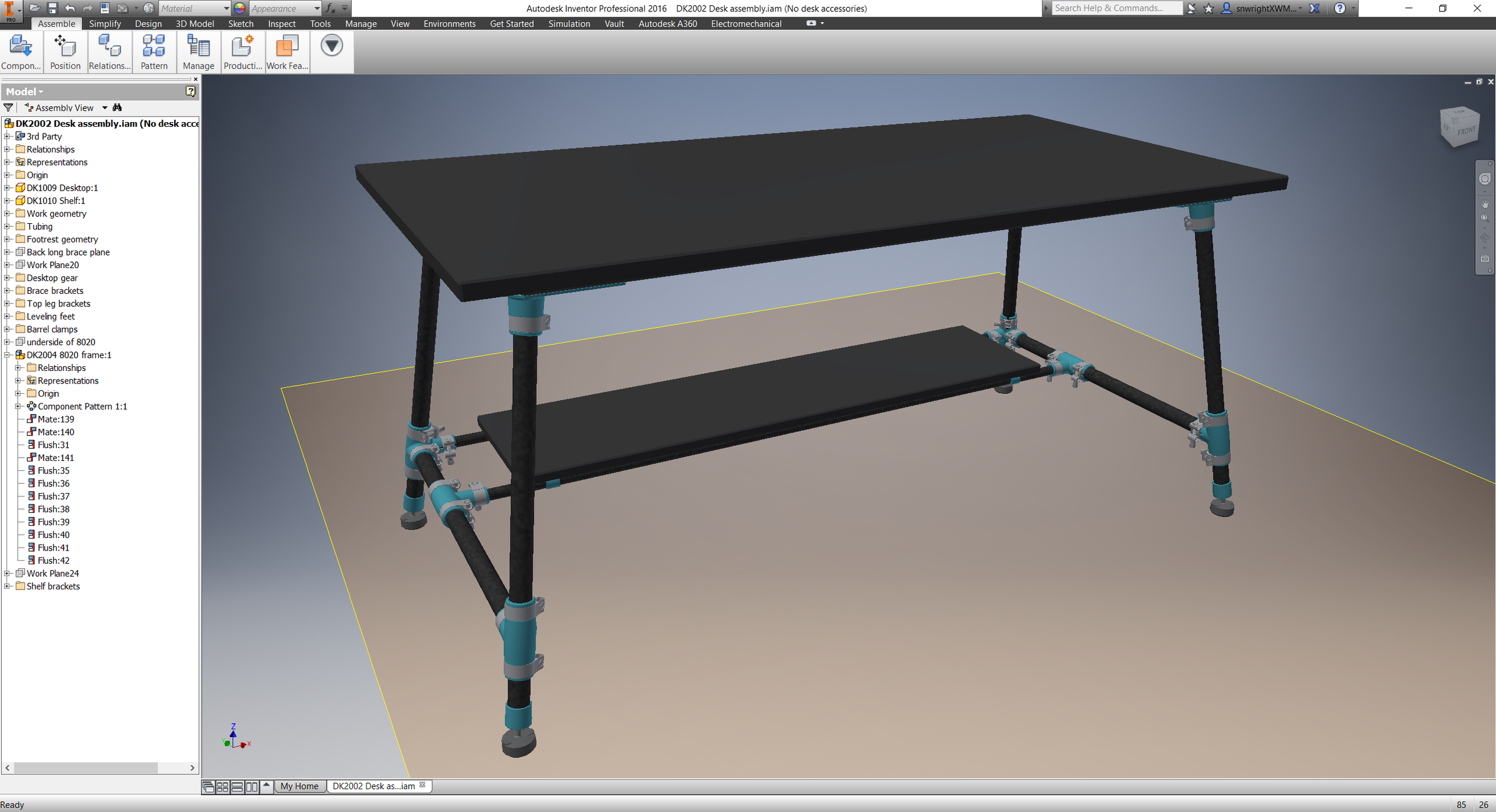

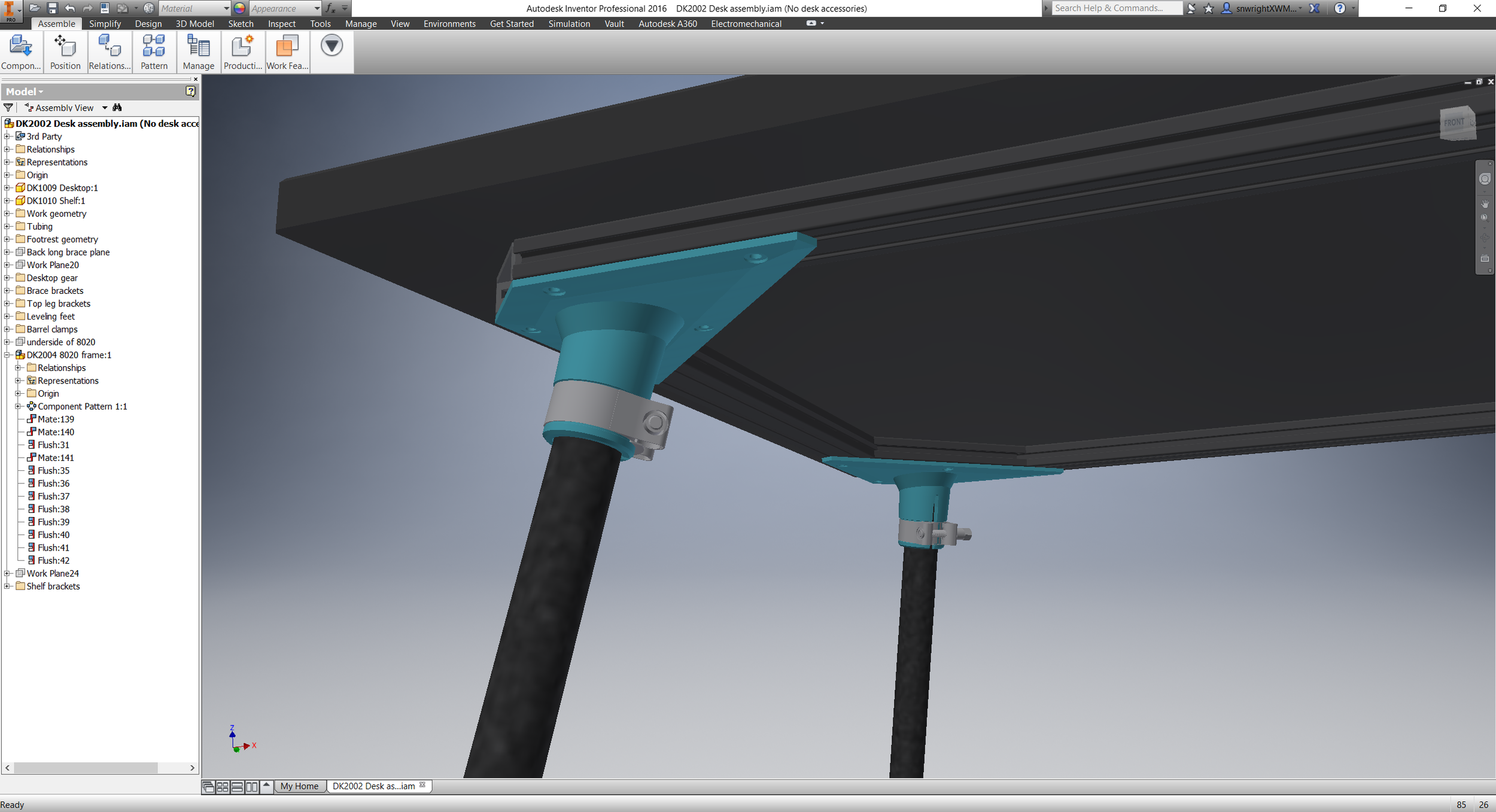

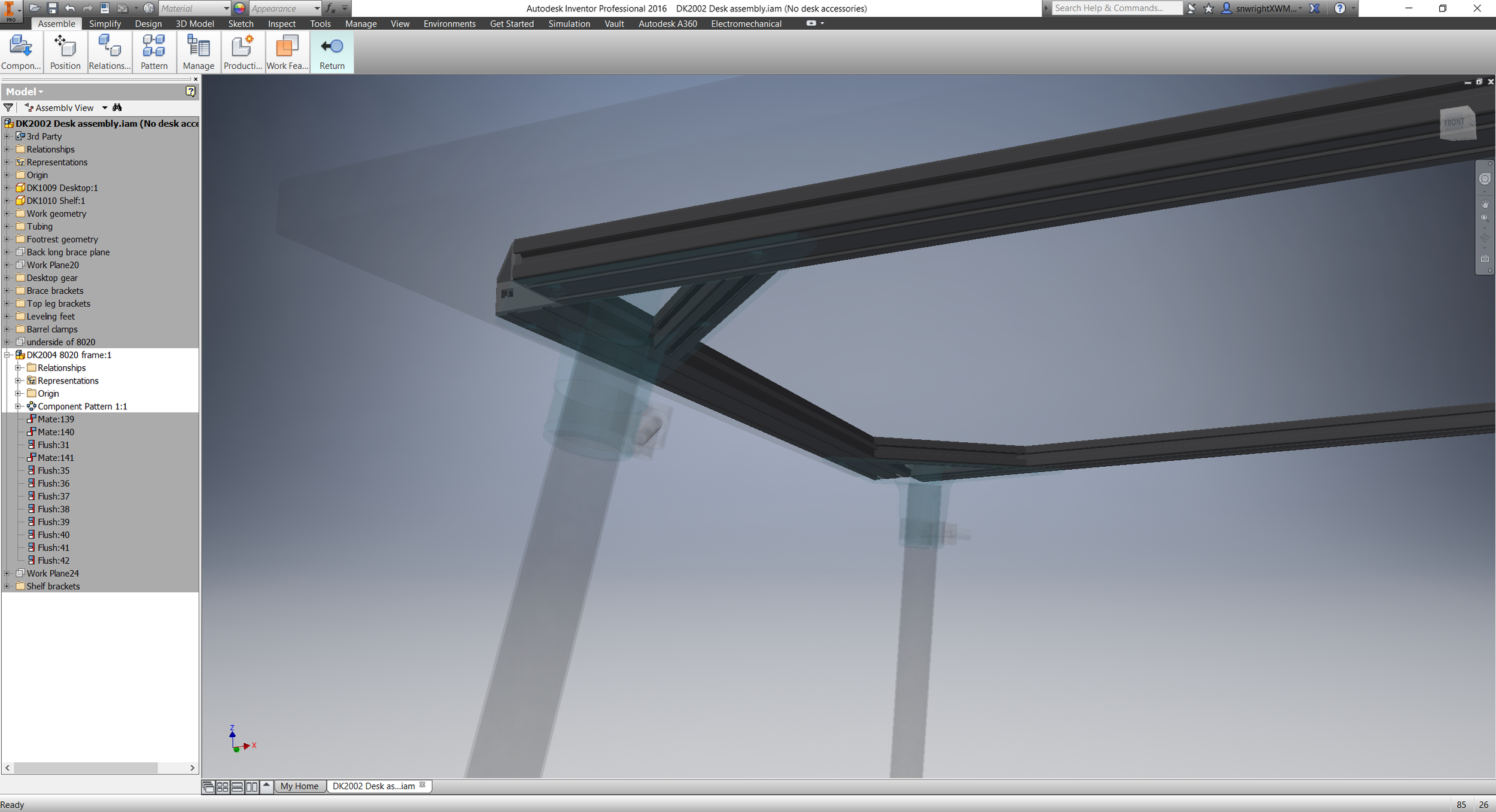

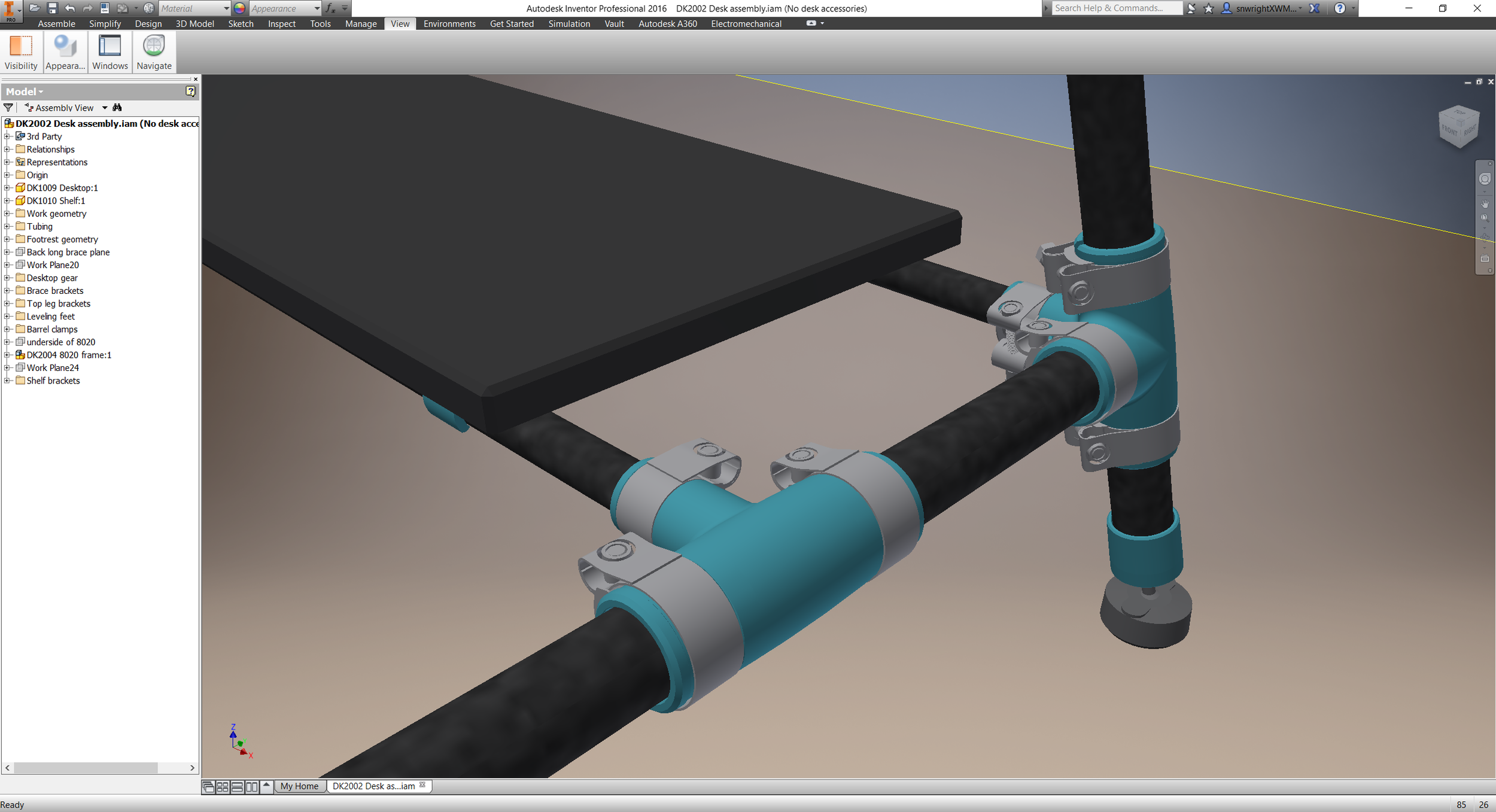

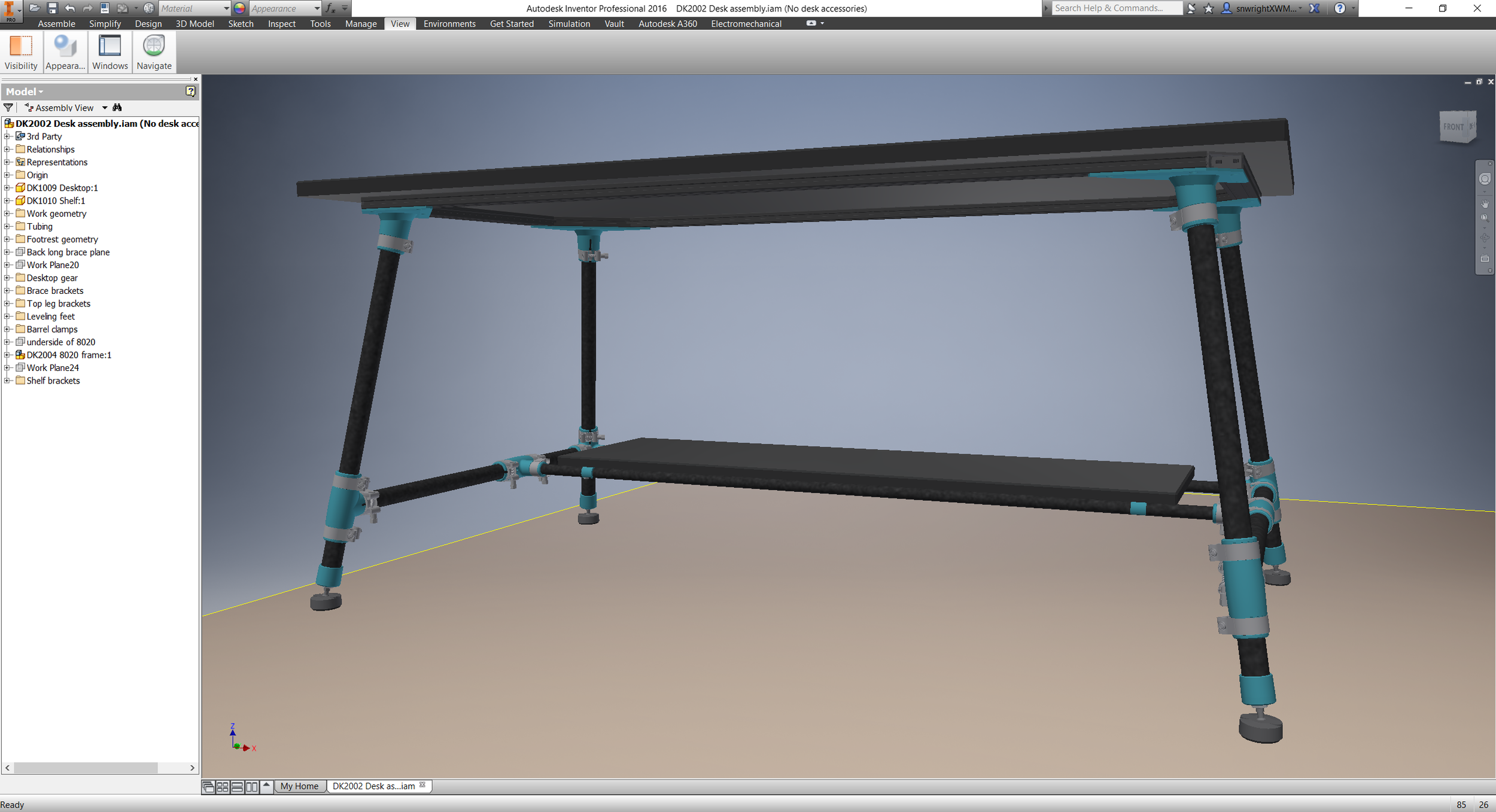

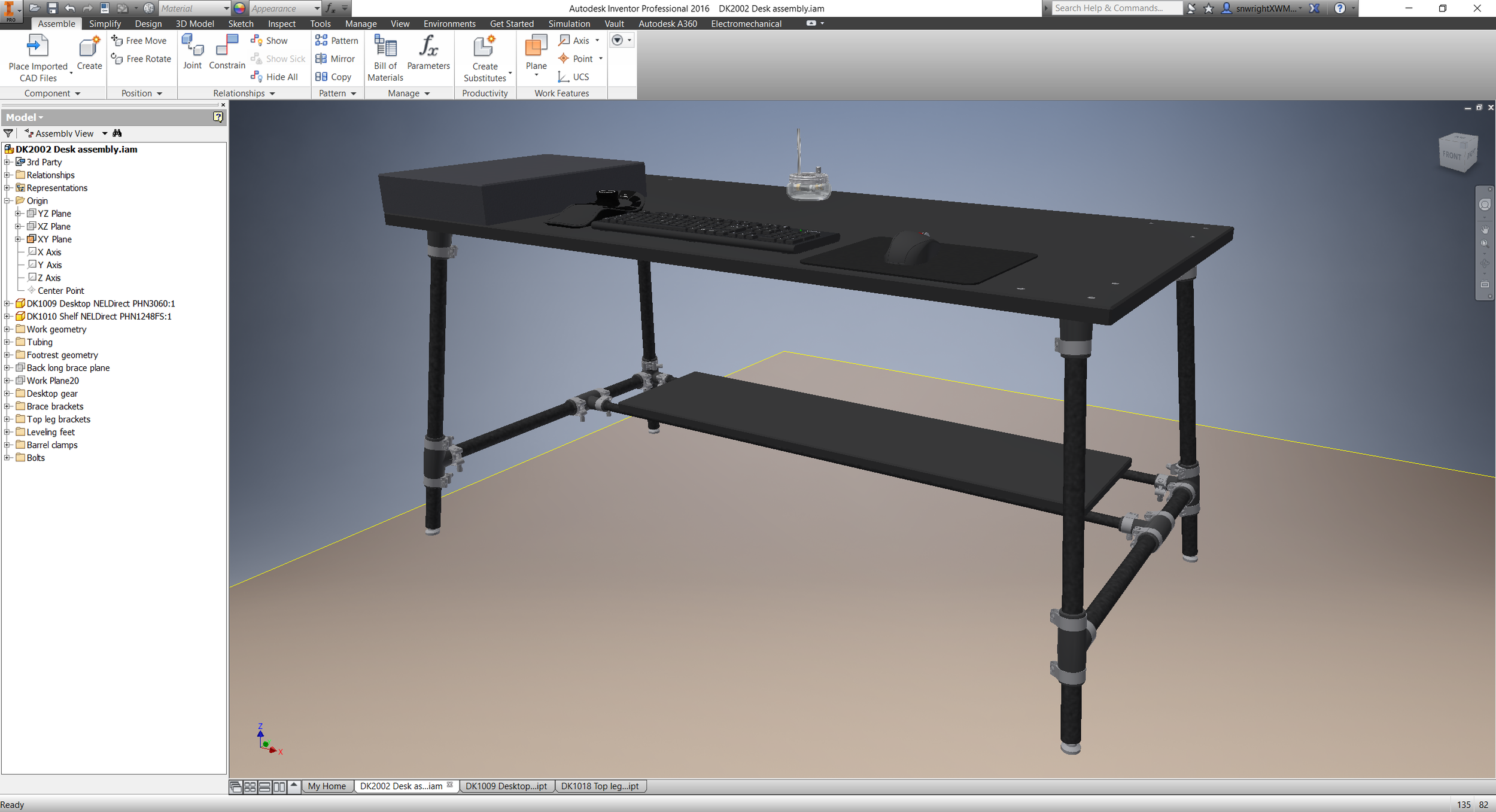

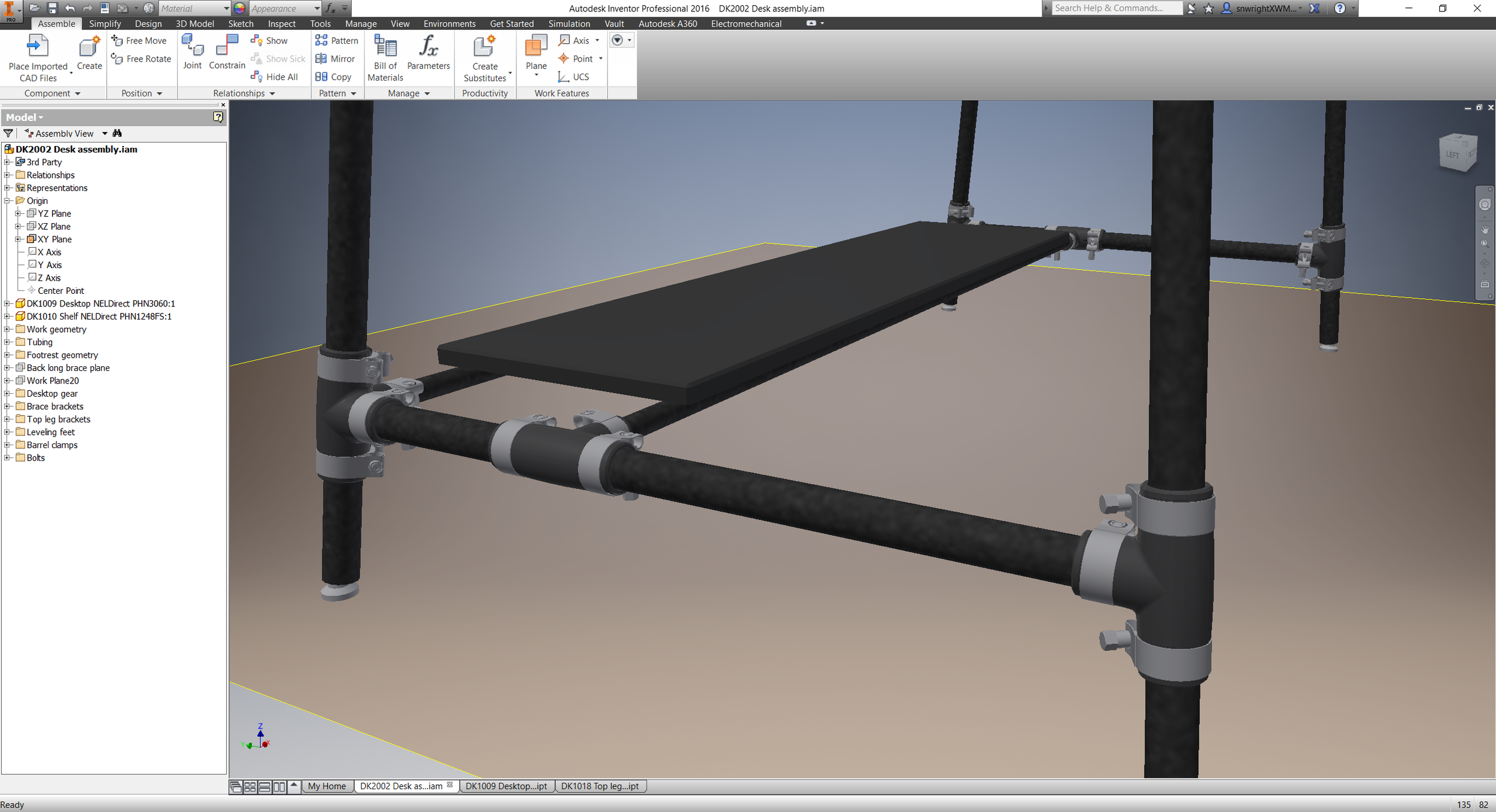

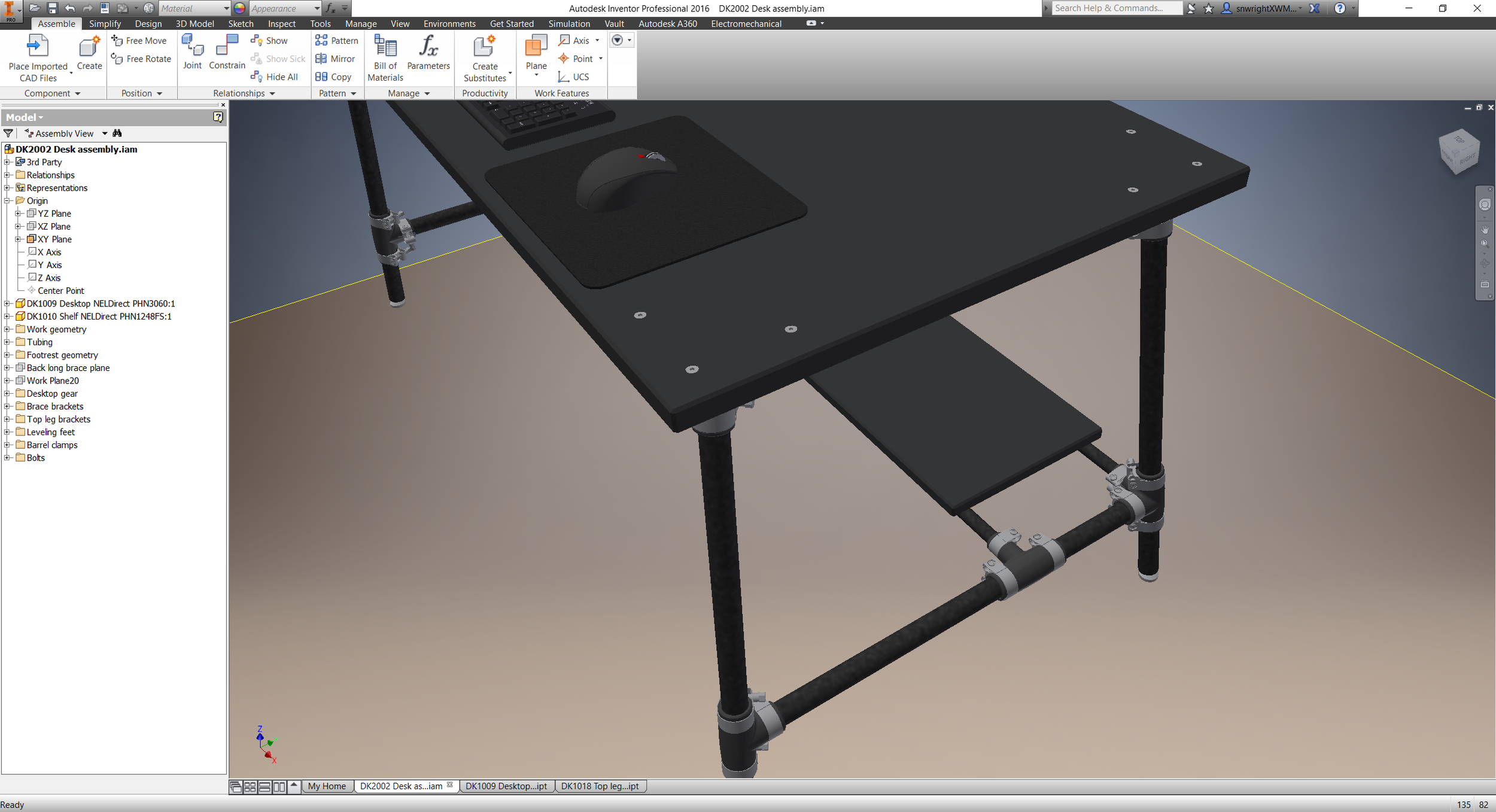

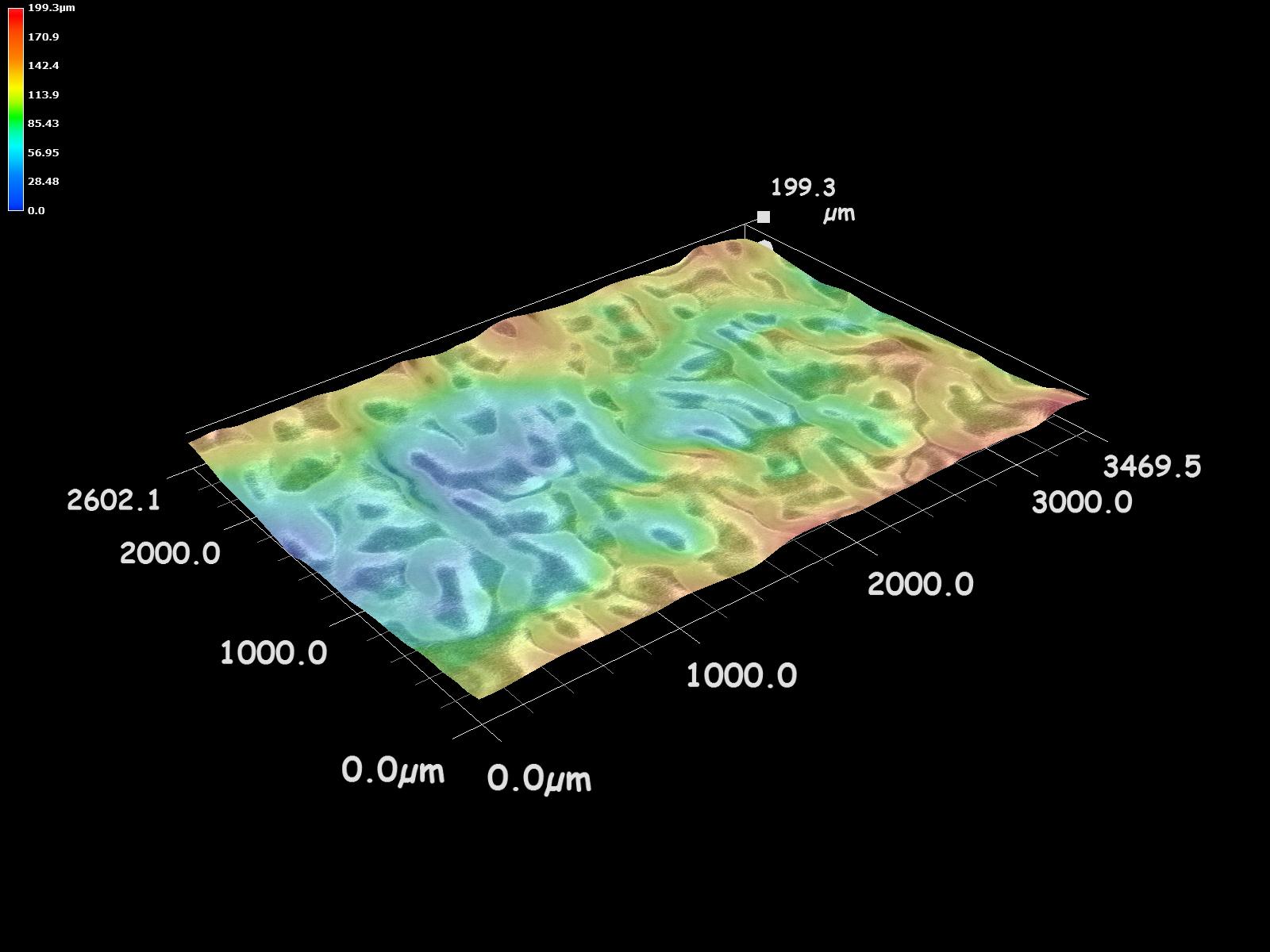

Most recently, I'm using a small amount of VHB tape to adhere the 8020 subframe to the phenolic resin top of my desk. I chose a thin tape - 1/2" wide and .020" thick - and am using it on the short ends of the desktop as a secondary fastening method (the primary connections are two M5 bolts). I'm using it here for a few reasons, which highlight VHB's advantages:

- It's really strong. Not as strong as a structural adhesive like DP420 (with its overlap shear strength of about 4500 PSI), but for applications like the ones above, VHB's ~100 PSI dynamic tensile and 1000 PSI static shear strengths are *well* within my design objectives.

- It's really easy to apply. In most cases, isopropyl alcohol is all I've needed to prep the surface, and it's kind of nice to not have to manually mix up epoxy or get out a mixing gun.

- It stretches to accommodate differences in CTE. In this way, VHB is *much* better than rivets or nuts/bolts, and has big advantages over structural adhesives as well. According to 3M, VHB tapes can be stretched up to 50% of their thickness, making them ideal for applications where dissimilar materials need to be bonded, or where some shock absorption & vibration dampening is desired.

- It has a predictable thickness. Glue is great, but planning for a consistent glueline can be tricky. VHB is available in a variety of thicknesses, allowing you to design the assembly just the way you want it.

- It's relatively easy to remove. Disassembling a glue joint can be a major pain in the ass, but VHB is just acrylic foam; if you can fit a knife into the joint, you can usually cut the tape in half and pull the assembly apart.

- It's easy to keep in stock. Glue is great, but inevitably I end up with a hardened tube laying around, or run out of mixing nozzles right when I need them. VHB doesn't need any supporting equipment, and is shelf stable for two years - whether or not you've opened the package.

Don't get me wrong - I keep a big selection of bolts on hand, and usually have a active tubes of cyanoacrylate, Titebond, and DP420 on hand. But my shop is much better for having VHB in stock, and my desk is much better off for having used it :)