For reasons I'll get into below, I've got a bit less to show for the past few days.

The major theme of the past eight months of my life has been to form a new path towards long term stability, satisfaction and happiness. Some of that has been personal: I've spent a lot of time with friends; I've done my share of dating; I've been about as physically active as ever. But a major component has been my career.

I'm skeptical about anyone who claims a high degree of authority over their own emotional state. I tend to think that statements of ultimate preference (e.g. "I could never be happy in finance" or "I'm not satisfied unless I'm building something") tend to fall to post hoc ergo propter hoc fallacies. I want to be happy, and I refuse to let my career get in the way of my happiness.

That said, I have a particular set of goals vis a vis my career, and high on the list is to be appreciated for my ability to break down complex problems on a range of subjects. And it so happens that the types of problems I'm interested in solving are largely strategic rather than technical, and it so happens that I see the most interesting strategic problem solving happening in the tech world.

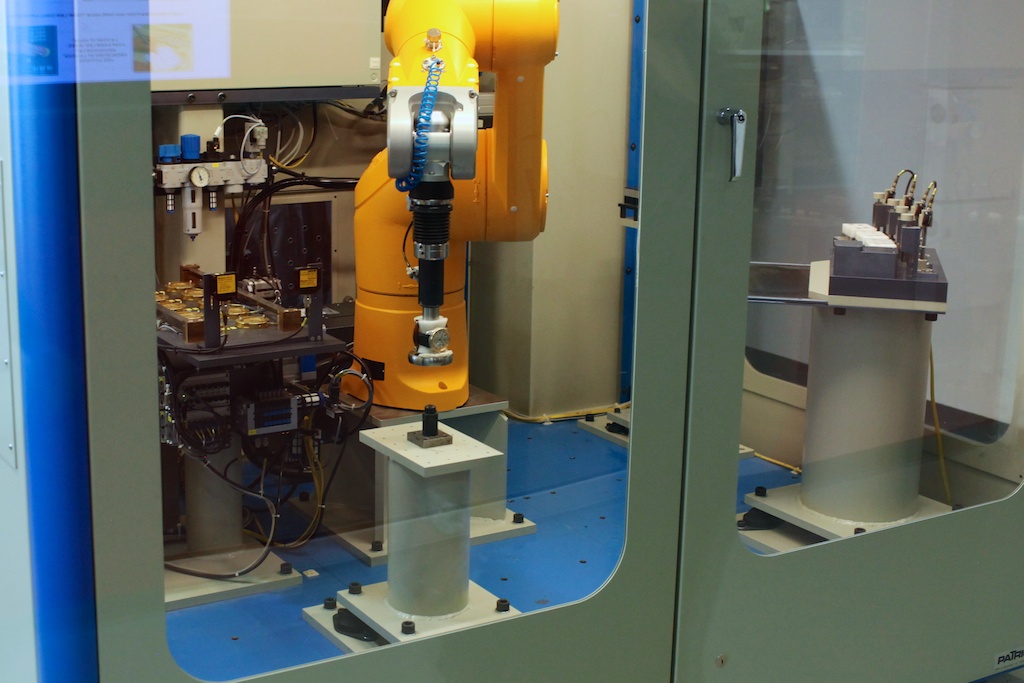

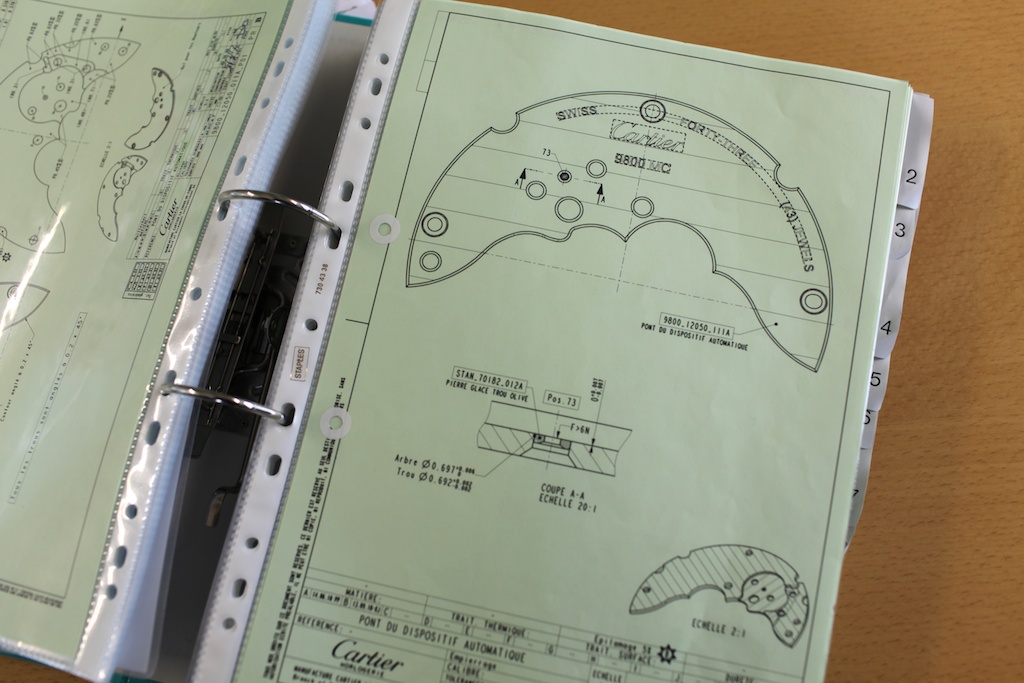

I have spent most of my adult life learning skills, but software development is not one of them. I'm probably more comfortable at a command line than the average person, and I can talk generally about a tech stack, but I am not a programmer. Except in certain contexts that fact doesn't bother me. I'm not an engineer either; nor am I a certified welder or a particularly well practiced machinist or carpenter. But I've got all of those skills nonetheless, and I've put enough time in on those types of projects to communicate well with people whose careers are dedicated to those crafts.

I don't want to be a developer any more than I want to be a bike mechanic. Skills are like tools - I like having them, but I'm wary of committing to any particular one, lest I view the entire world through a single lens. Some problems require a hammer; some require knowing the first damn thing about how serial port emulators work. I want to be a general purpose problem solver; I want to bring a wide variety of skills and experience to the table. I want my range of conceptual frameworks to be broad. I want to be intellectually agile.

Also - and I don't mean this to be trite - I like computers.

So Zach and I spent most of yesterday doing an overview of the tech stack required for a basic web app. We've got a couple of ideas that would fall across hardware and software, and it would seem that an RoR backend would fit our needs nicely. We'll still probably be programming our hardware in C, and will have a bit of HTML/CSS on top, but the meat of it - and, really, the fun stuff - would be Rails.

So today, we got about a third of the way through the Codecademy Ruby class. The Codecademy site is pretty slick. It's weird doing programming classes in this context, though. I took a few CS classes in college, but that was before laptops were ubiquitous, and I never really got comfortable with the format. Doing Codecademy is a lot cleaner - I like having the instruction and the execution all in one interface - but there's something about it I haven't gotten totally used to yet. I suspect that'll go away, but it was there a little bit today.

I'm excited to bang this class out over the next few days. I'd also like to be making concrete progress on a project, though, and it's hard to know how the two mesh. Not wanting to be a developer puts me in a weird position in the tech world. I'm a bit of a spectacle - a guy who swatted nails for a few years and can talk with some conviction about the benefits of climb milling. For the most part, that's fine with me, but the romanticism that the tech world has for physical objects - and old ones in particular - strikes me as a bit condescending and disrespectful. And all things being equal, I'd rather not be the one being condescended to.

But, whatever. Sorting hashes is fun, and I relish the opportunity to flaunt my command of logical structures. I'm enjoying learning a new skill, and if history is any guide, I'm sure I'll find a way to put it to use.