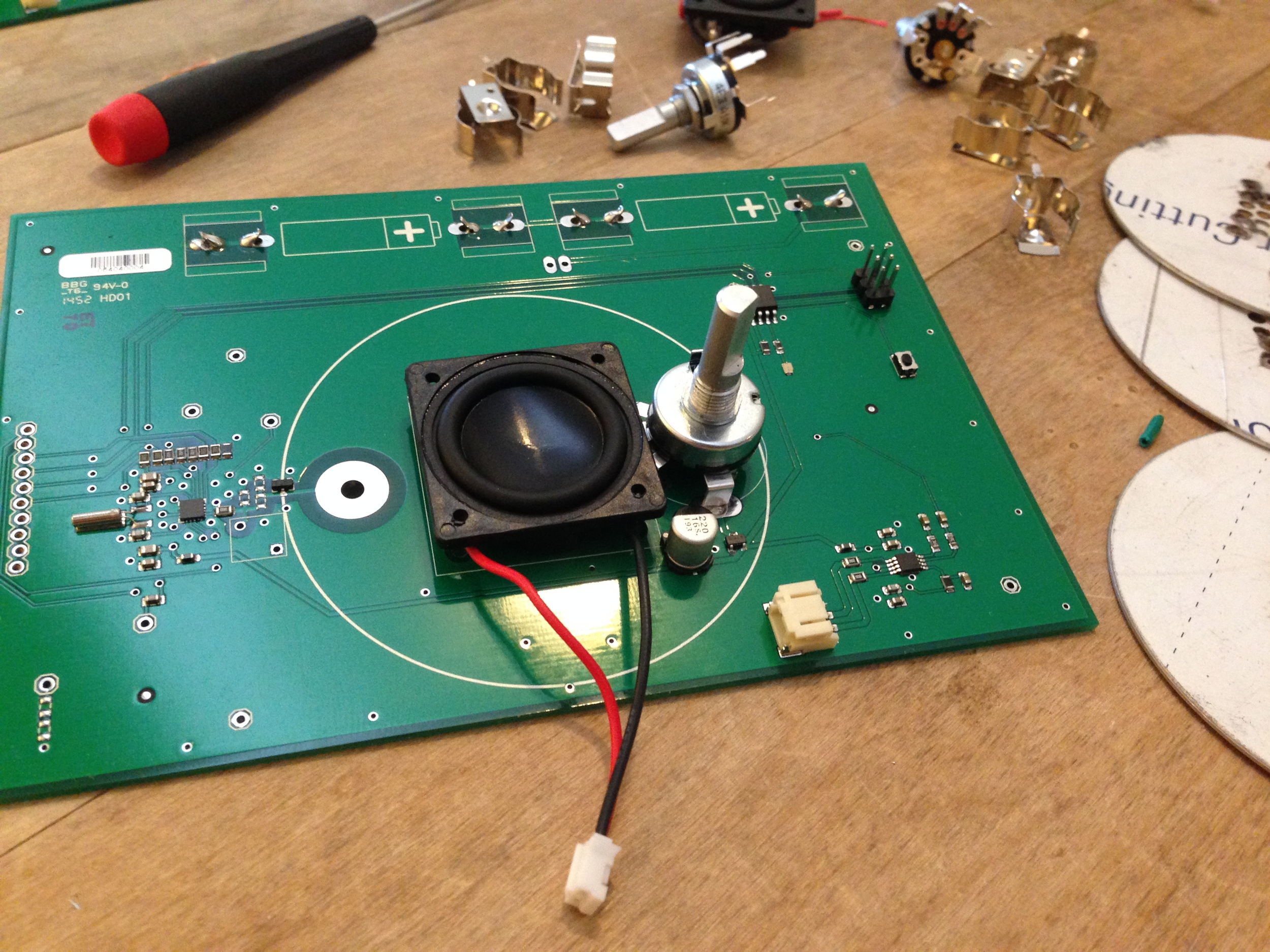

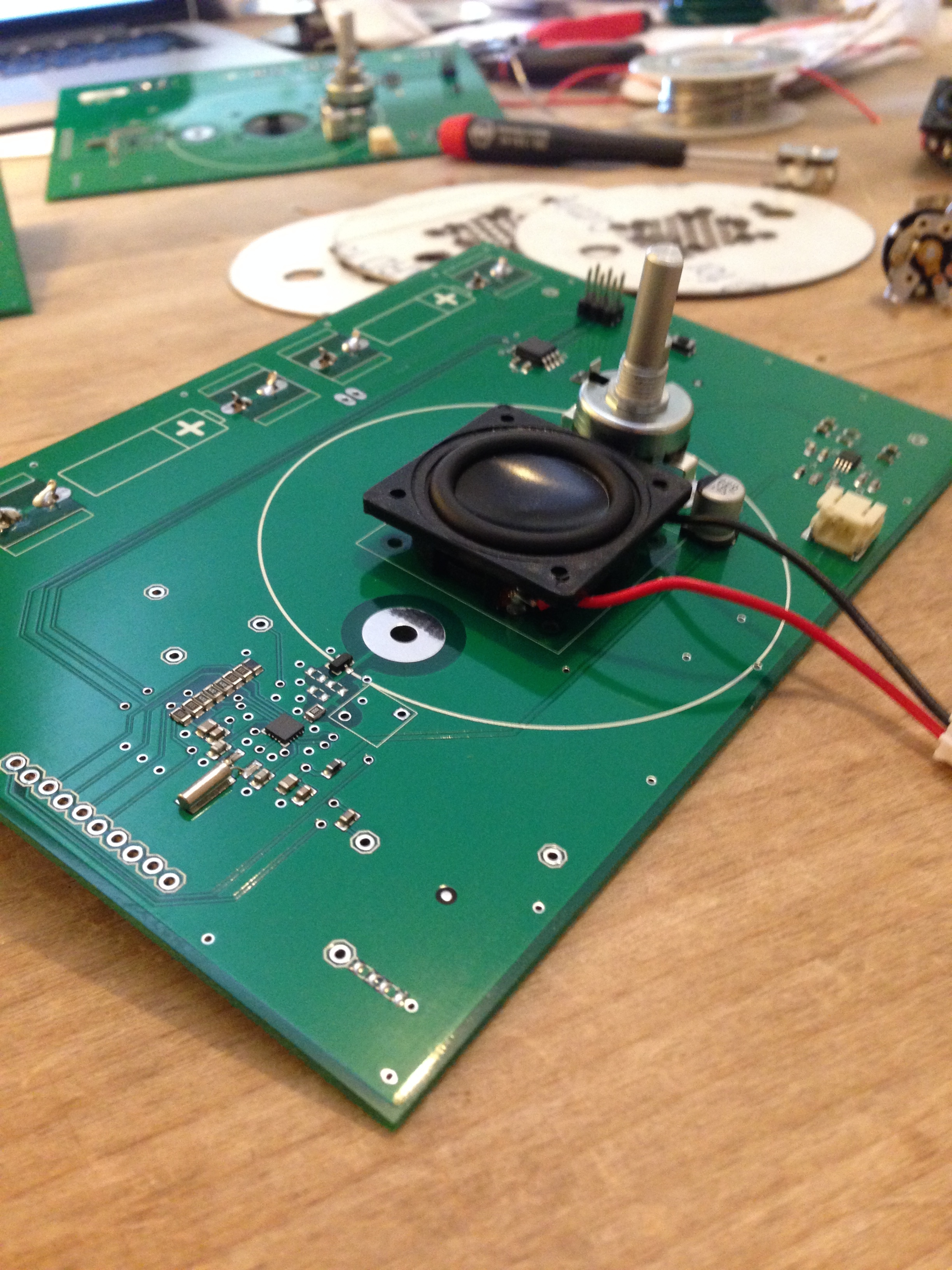

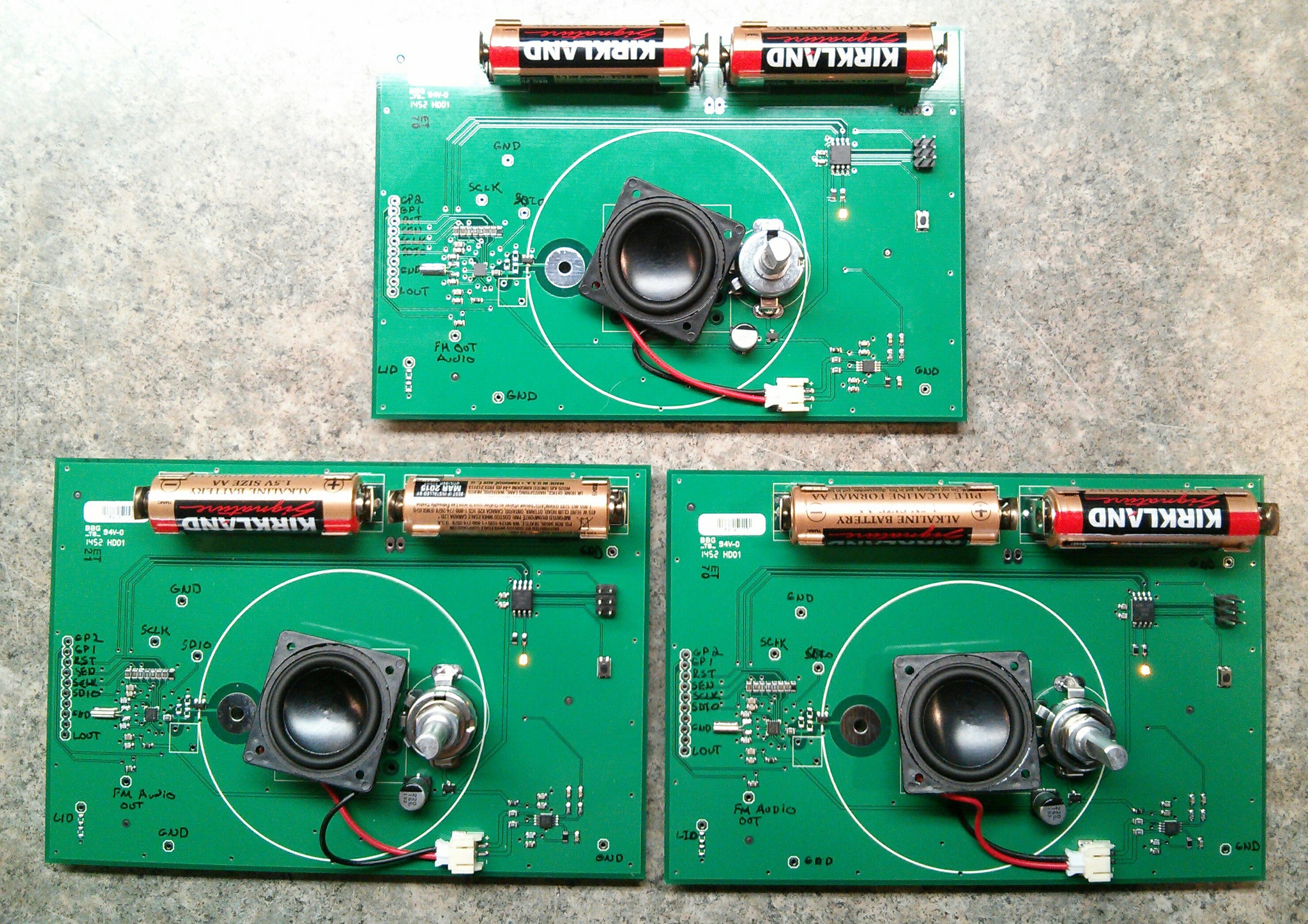

Ada asked the question late last night, just as we were going to bed. It's been a long week, and I've worked until about midnight every single night. That's been the case for most of the past six months: In general, if I'm not working on The Public Radio it's because I've spent all evening clearing my inbox out, or writing my newsletter, or (as was the case much of this week) working late on Undercurrent stuff. And if I'm honest, the same could be said for most of my adult life.

Regardless, though I suppose by way of a technicality, I've never considered myself a workaholic. I think of a workaholic as someone who is addicted to work - to whom the goal is working itself.

I want freedom, though. I want to be recognized for my intuition, and my intelligence, and for the effort I put into the things I do. I want people to say "He doesn't fuck around. And he notices real stuff, and he turns his observations into really valuable output - whatever the form." And then I want to be given the benefit of the doubt - the freedom, both creative and financial - to do just that.

It's possible - likely, even - that my efforts are misguided. At least within traditional working environments, and even at companies that espouse two pizza rules and generally empower their employees (I'll pause here to note that Paul Graham's How to Make Wealth, and especially the section titled "Working Harder," is an absolutely excellent discussion of this topic), the value of individual contributions is extremely difficult to measure, and it's correspondingly rare to have one's individual efforts result in the kind of graduation that I seem to want. And moreover, one might argue that the freedom I'm looking for is a Macguffin: Once I get this recognition, what will I do with it? Work?

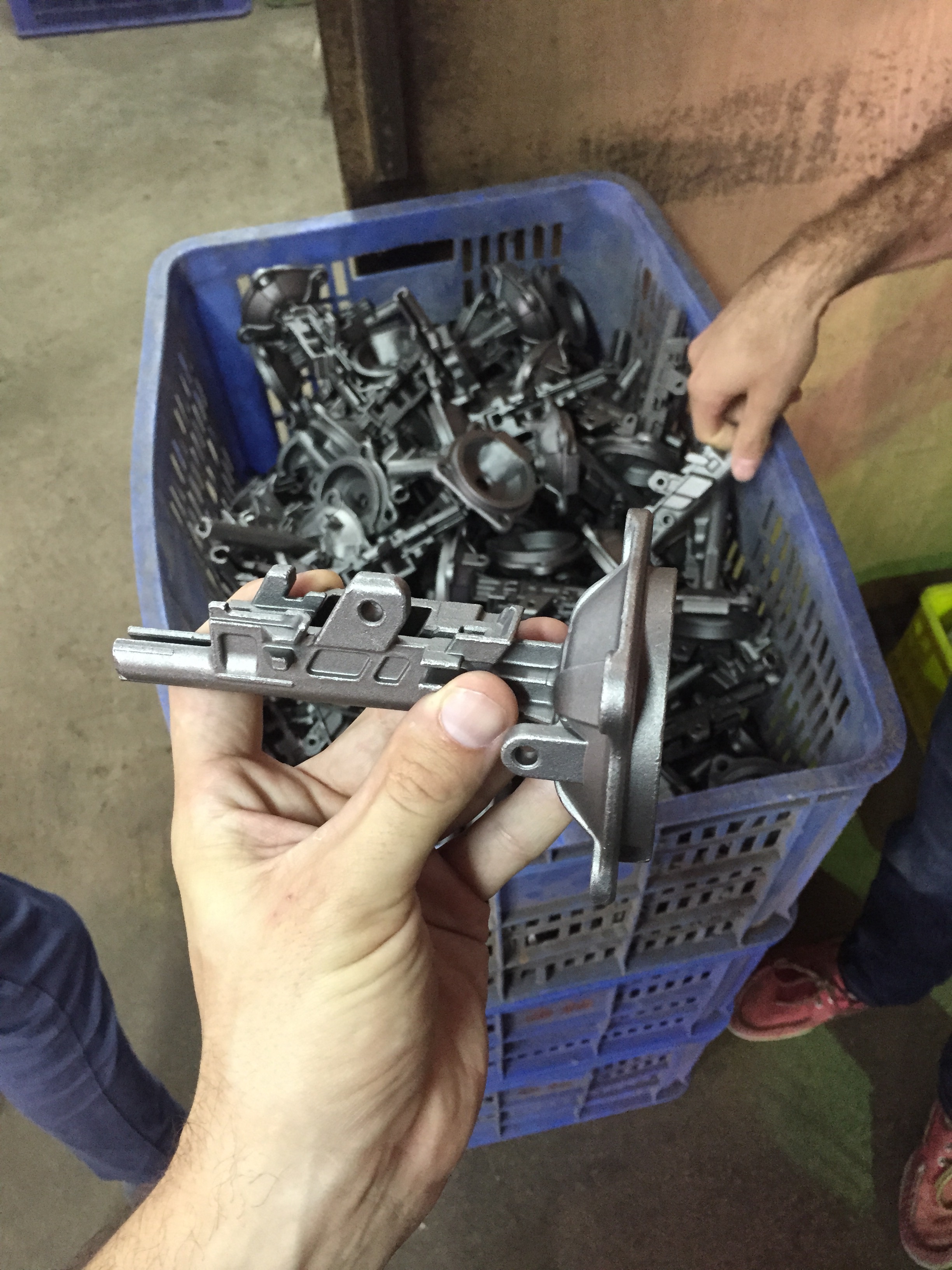

And yet, I continue. Even as I lay in bed, I was thinking of what I wanted to do over the weekend, with the explicit intention of carving out more breathing room for myself. And I awoke this morning feeling no different: There are things I want very much to work on today, and in my mind I can see how they add up to something more than the sum of their parts - to myself, my users, and to, I hope, the future of my creative path.