As I've written here before, the field of high performance surface finishes is fascinating - and complex. Surface finish plays a big role in the mechanical and aerodynamic properties of a part, and (in the case of consumer products) it can have a huge effect on marketability too. And so, as I've gone through the process of developing my titanium 3D printed bicycle seatpost, I've been conscious to evaluate many different surface finishing options to find a manufacturing process chain that's both effective and economical.

And so, this past spring, I reached out to Dr. Agustin Diaz to see how REM Surface Engineering could help my parts.

For a bit of context, allow me to quote myself (from EBM surface finishes and MMP):

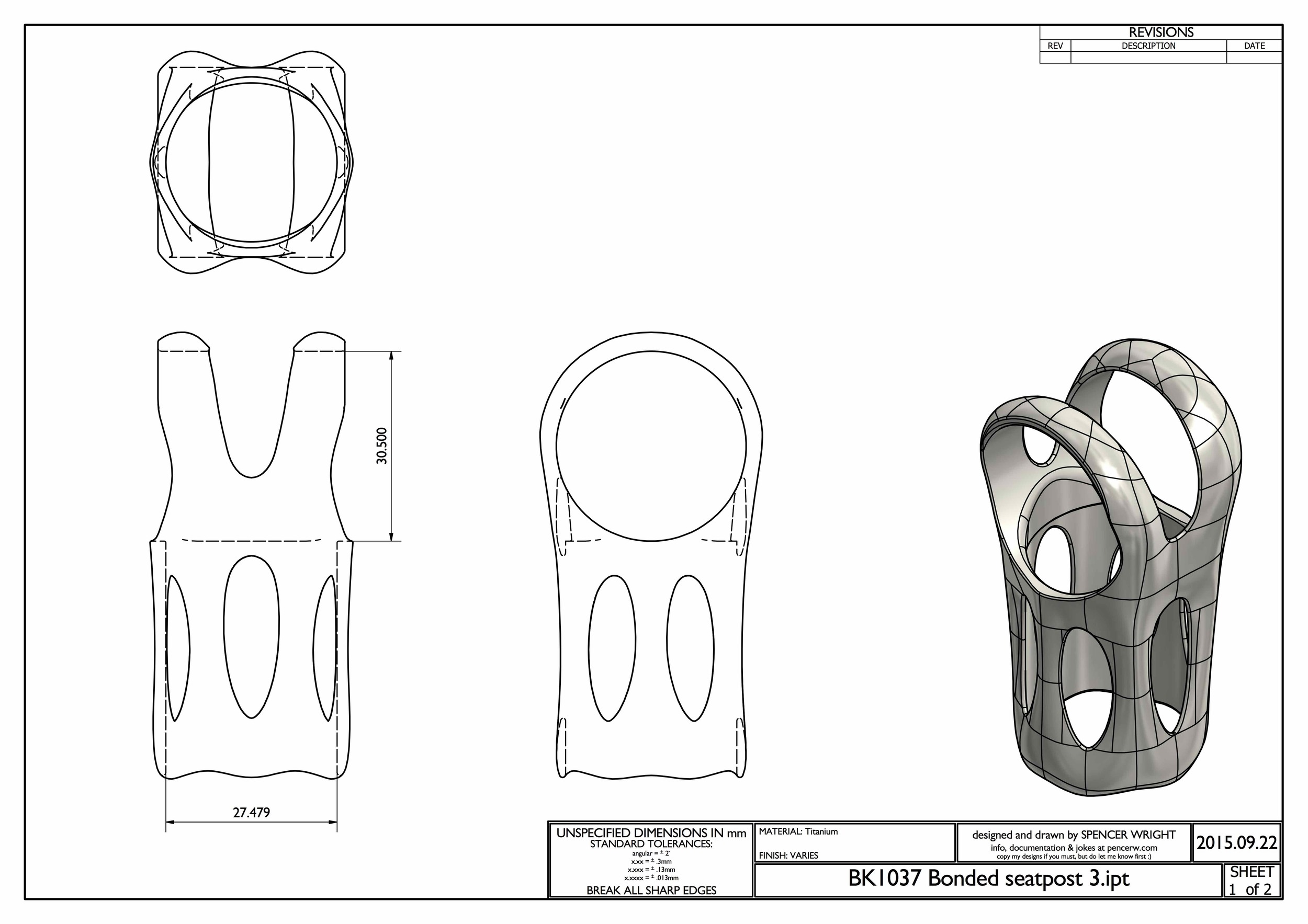

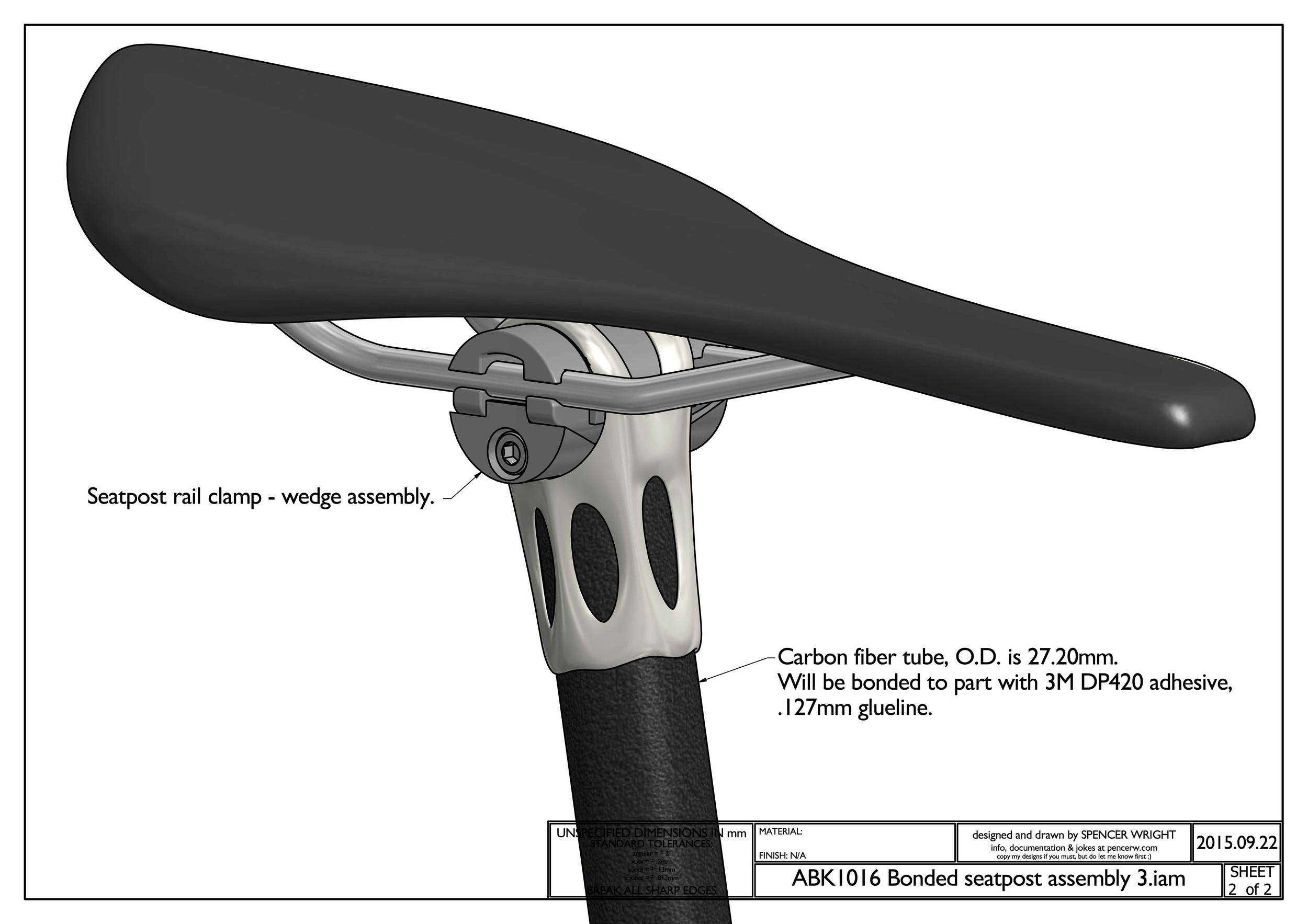

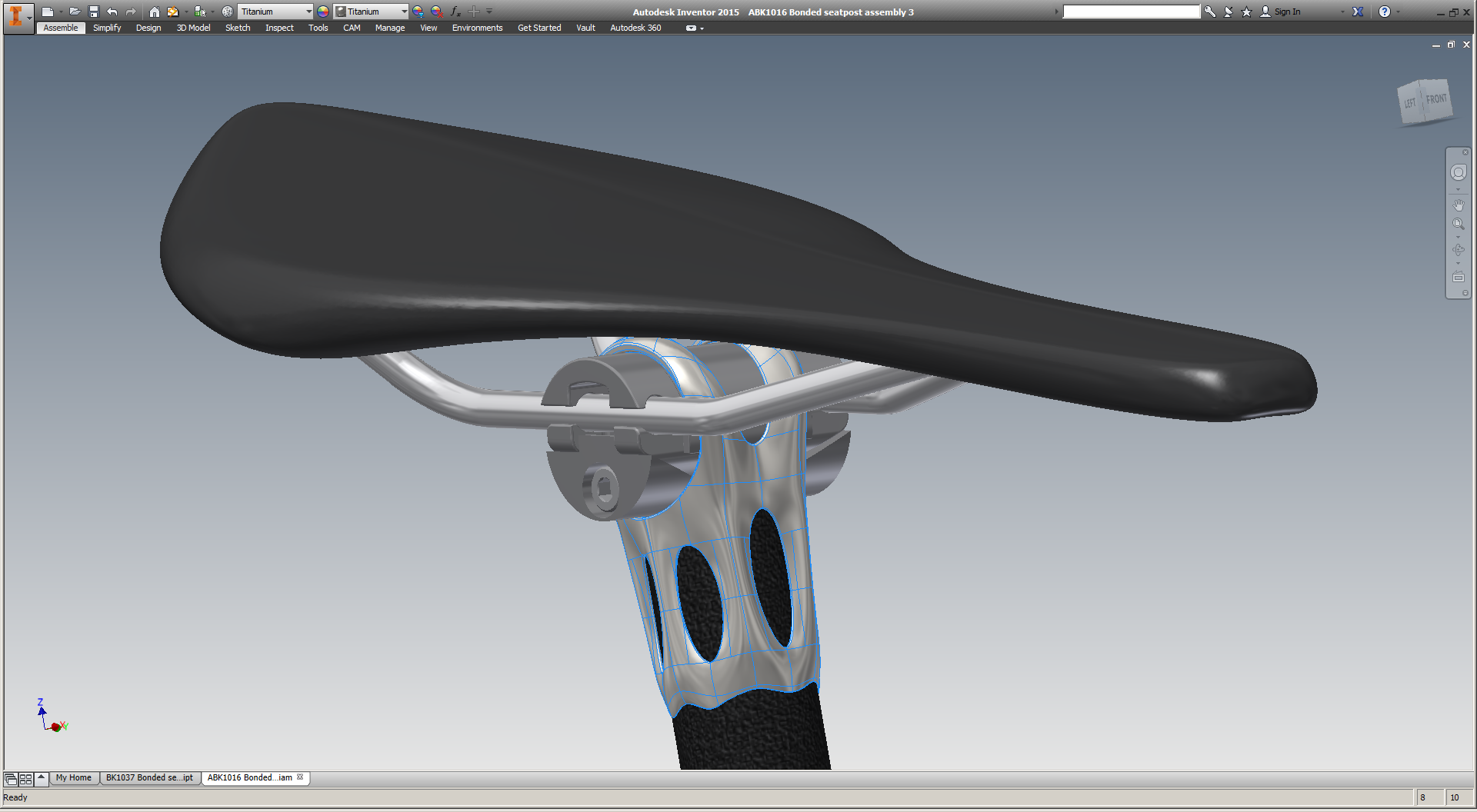

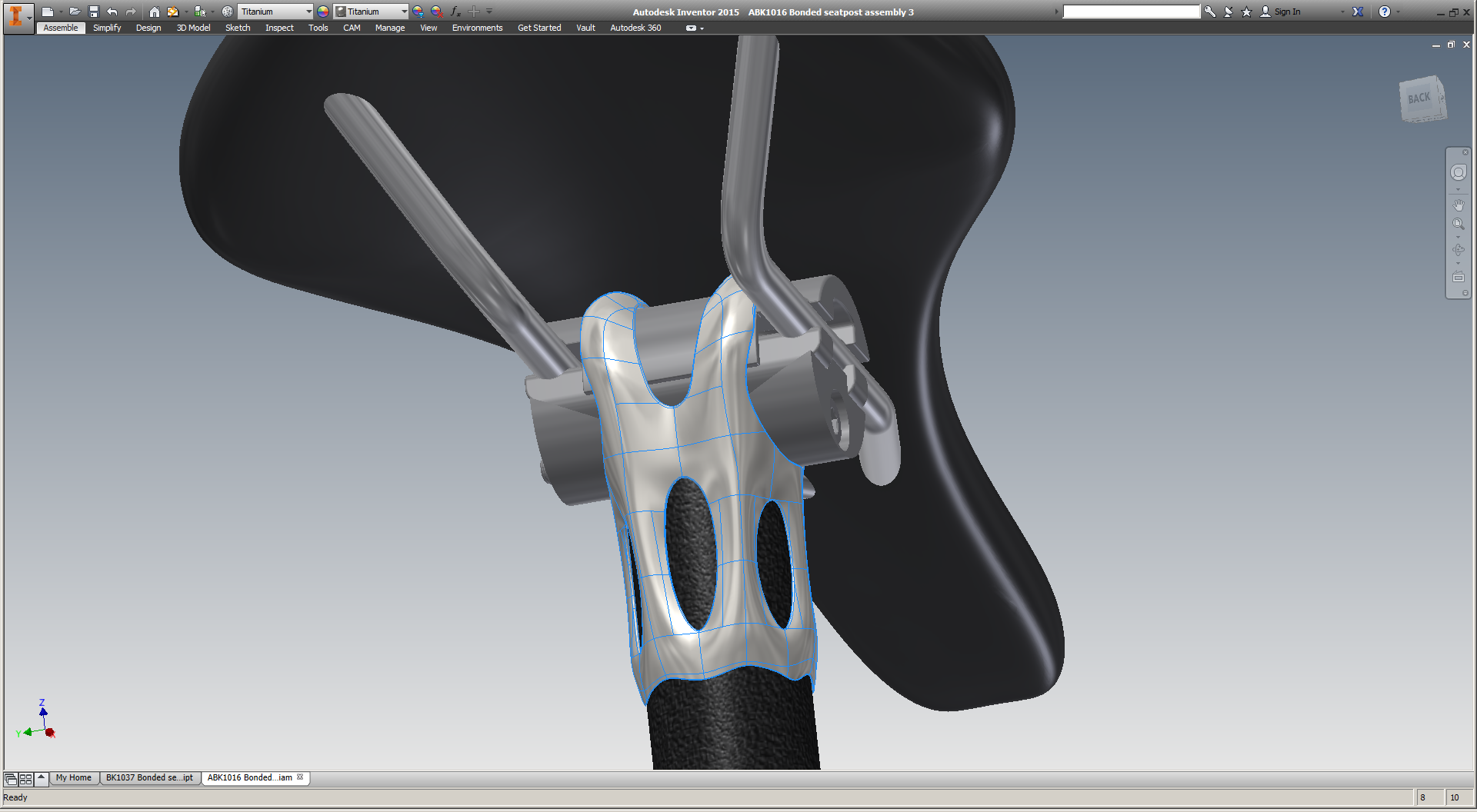

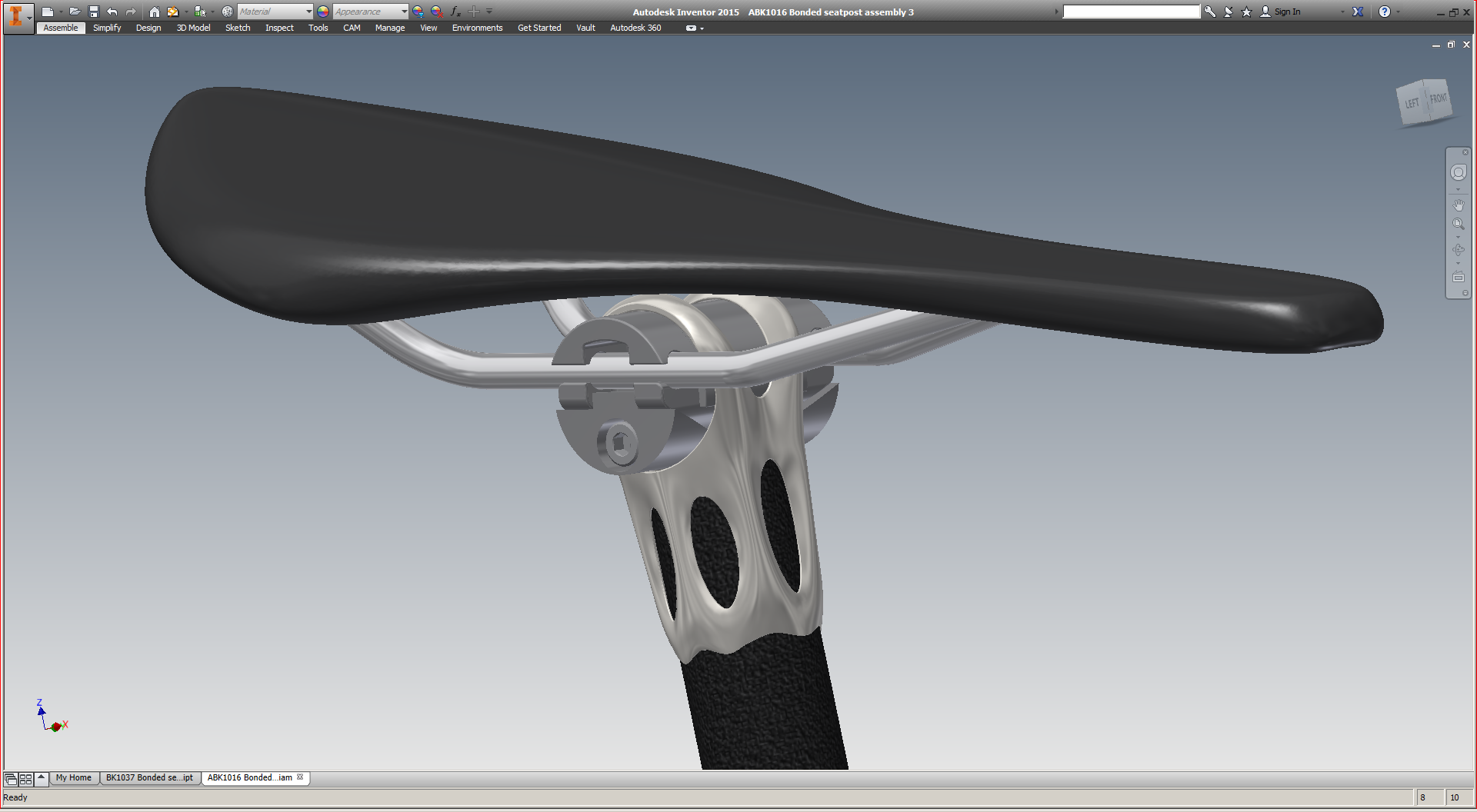

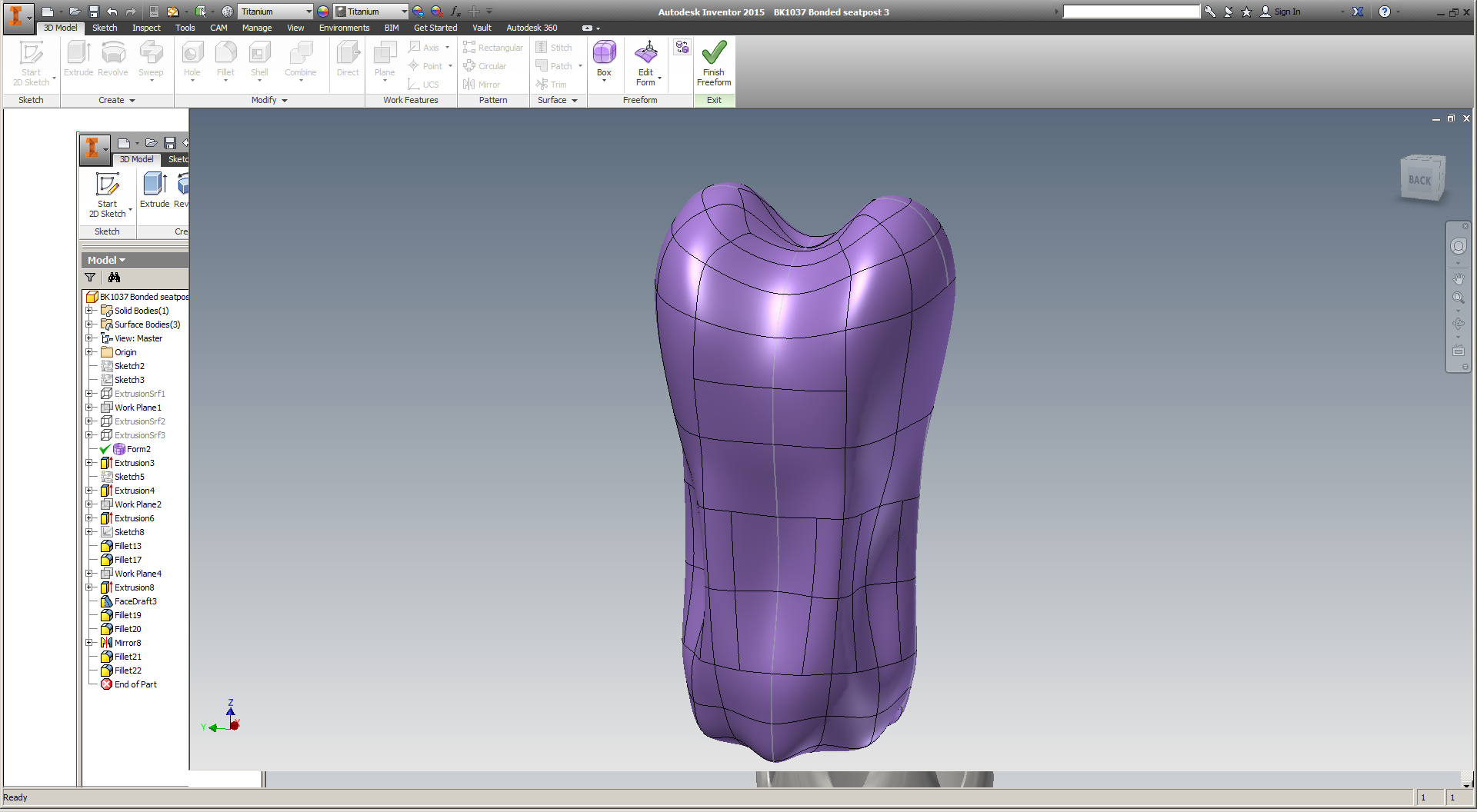

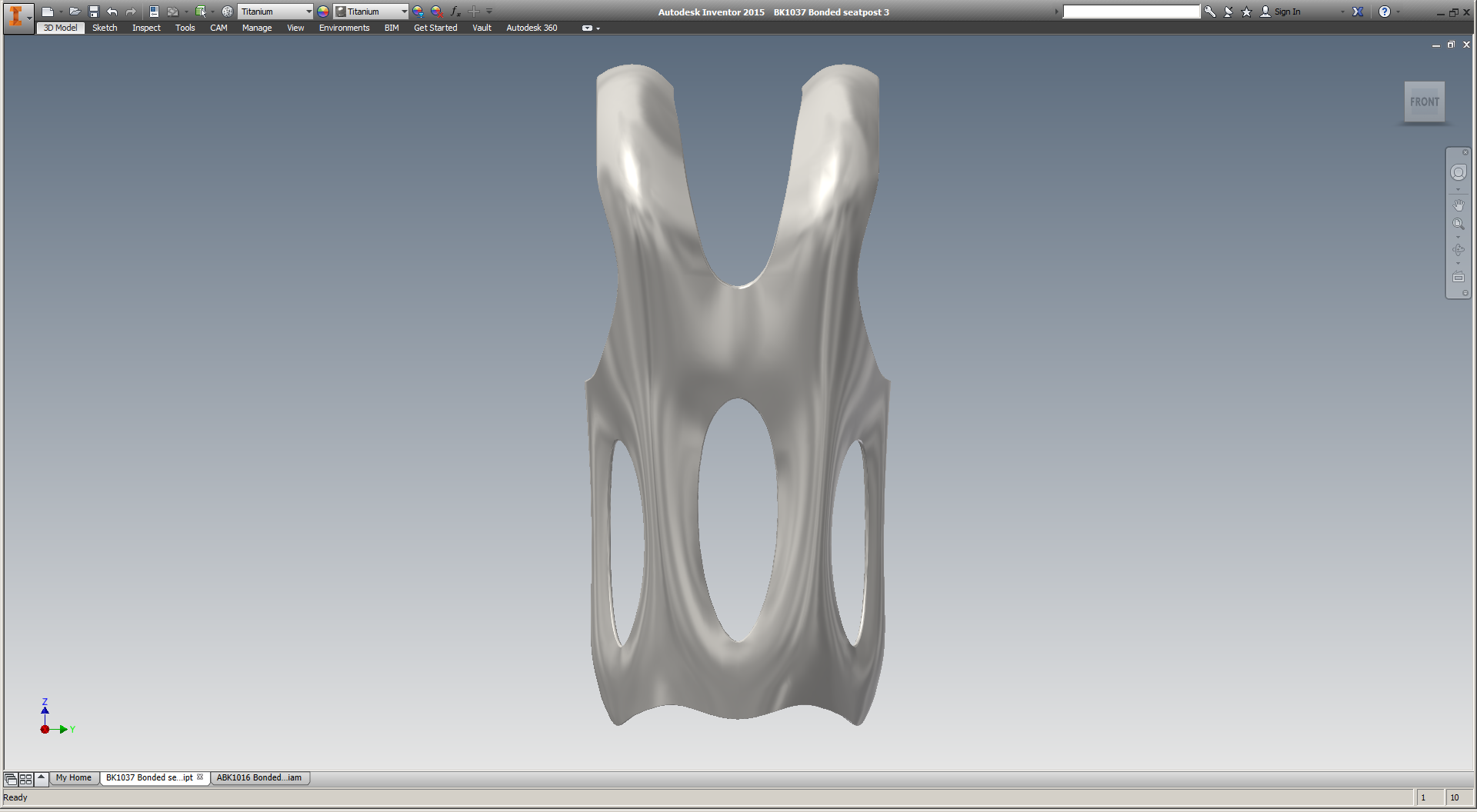

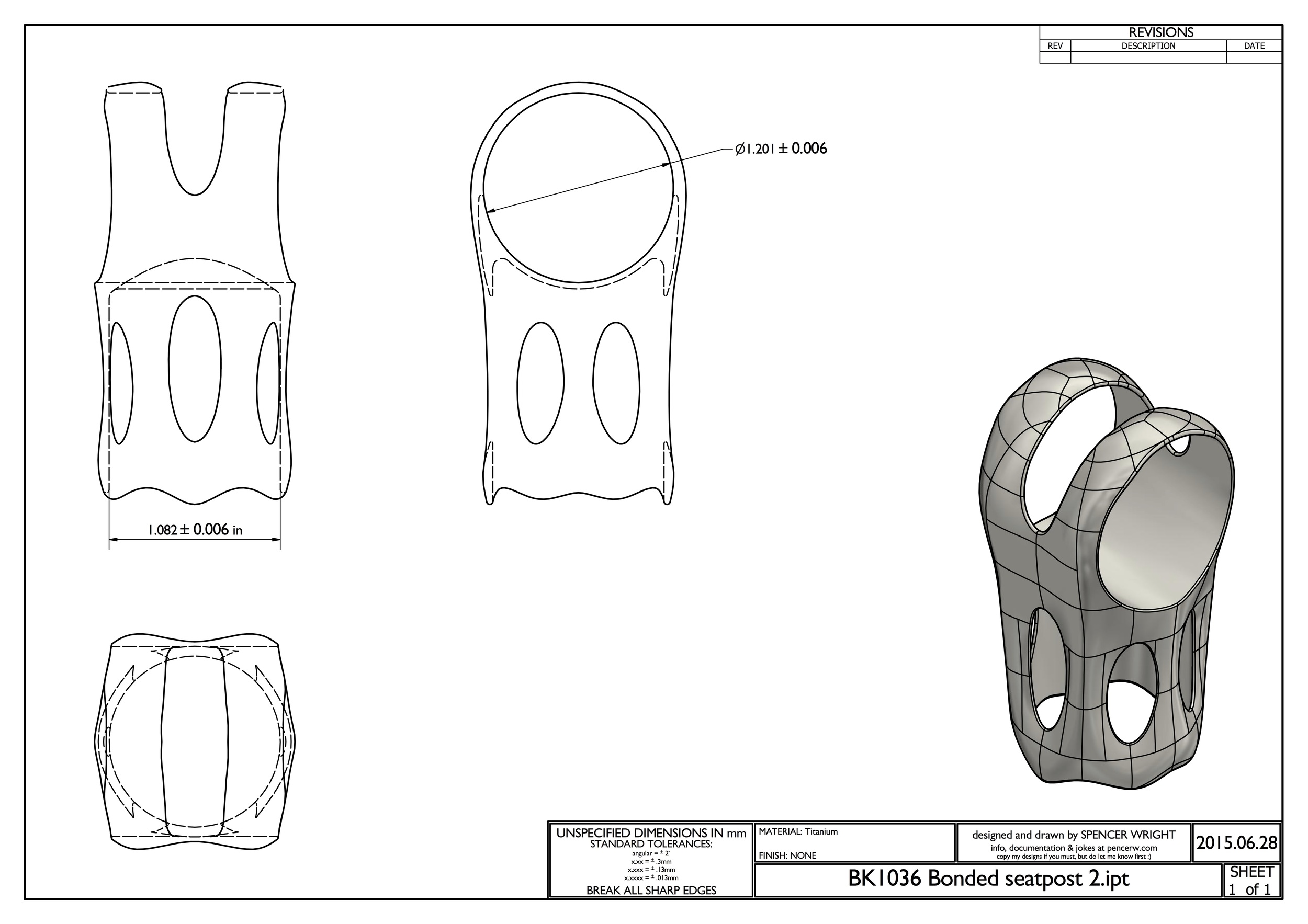

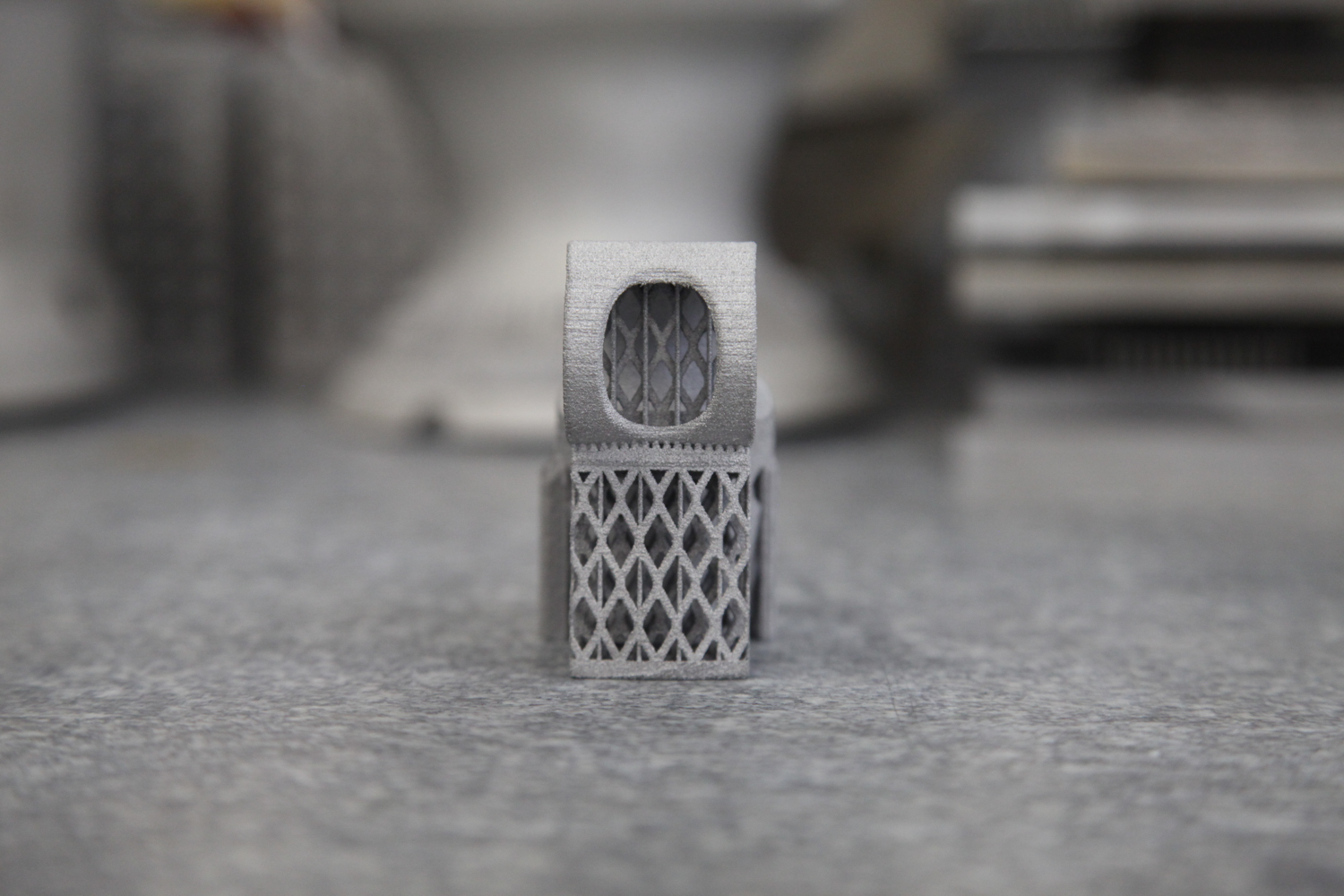

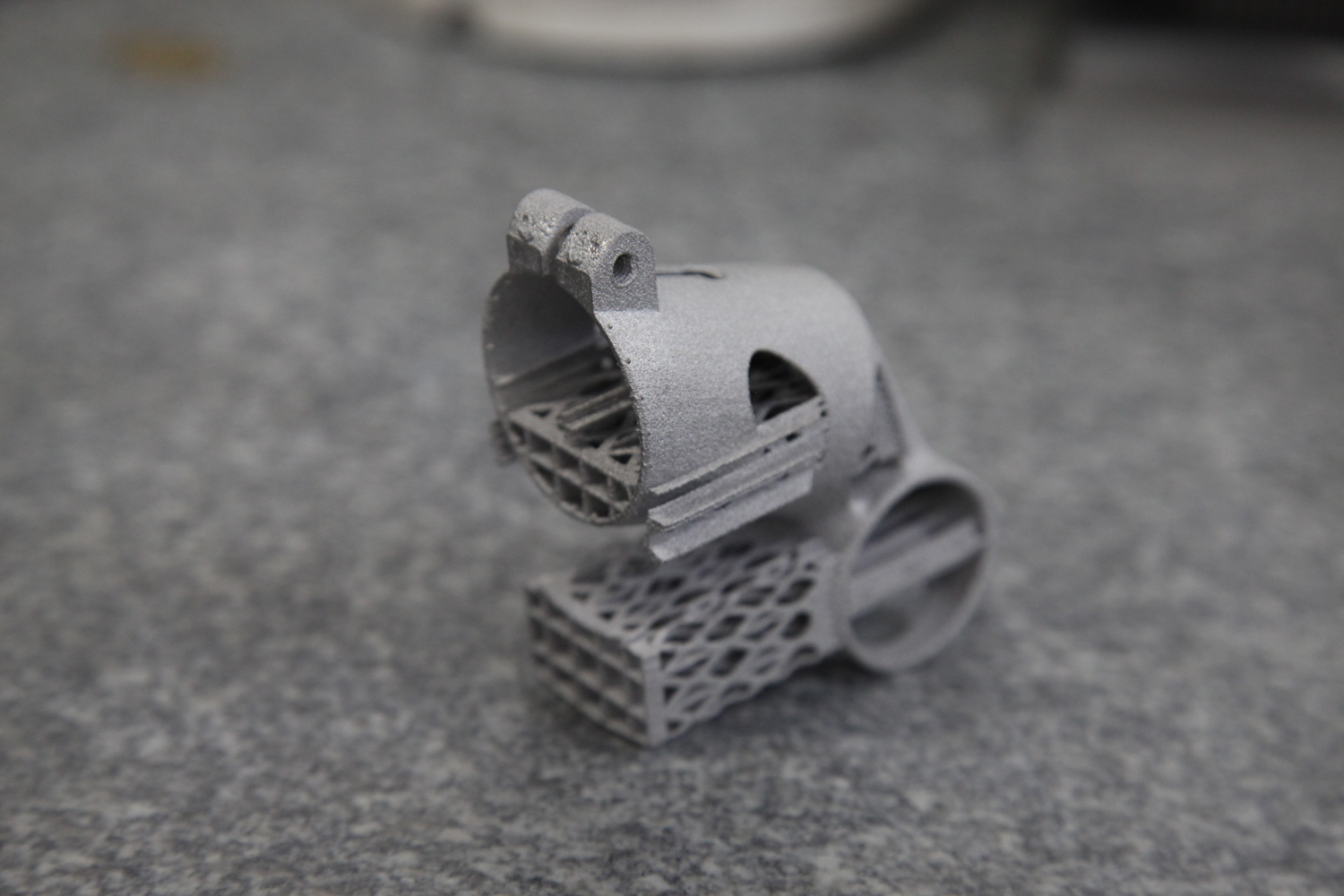

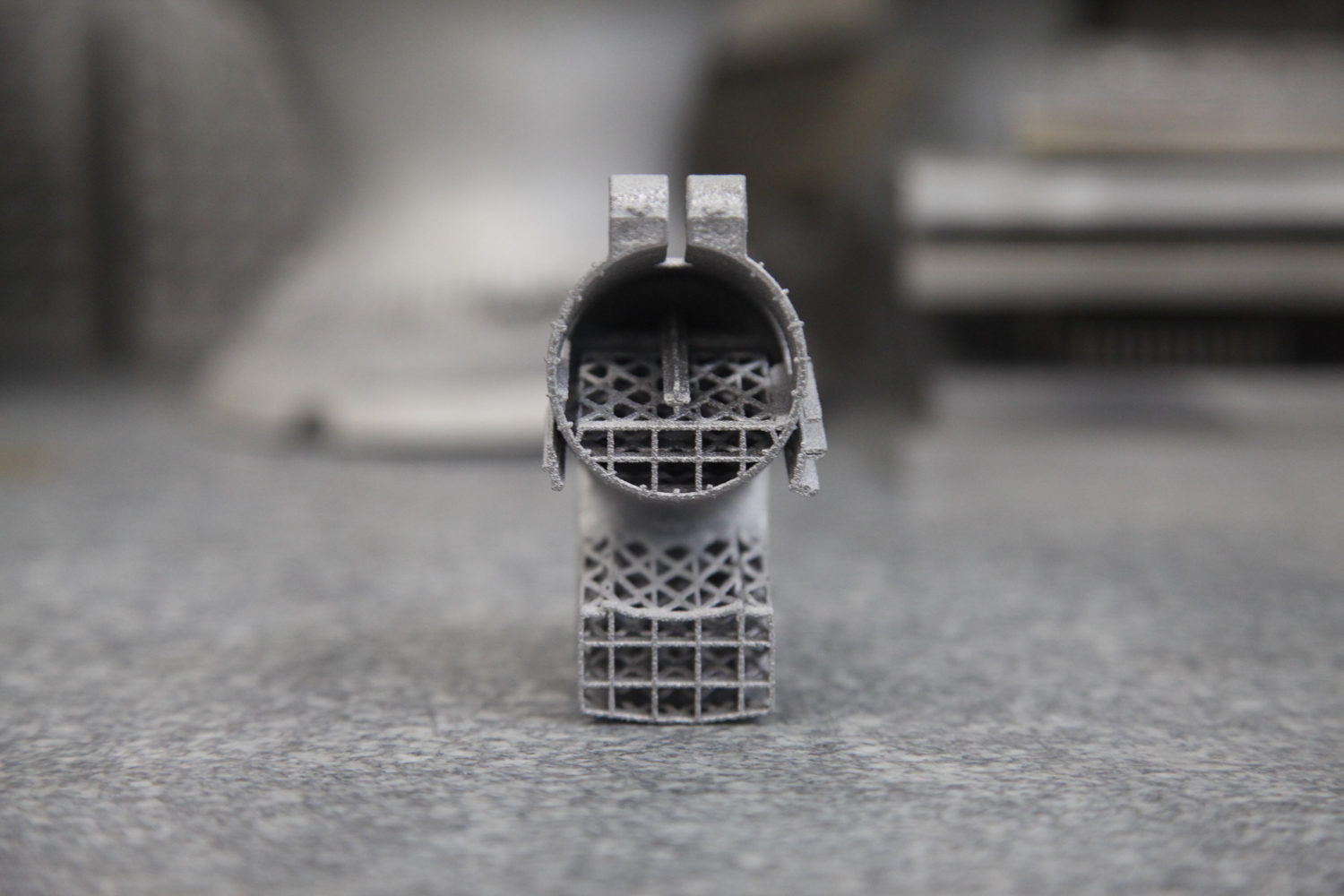

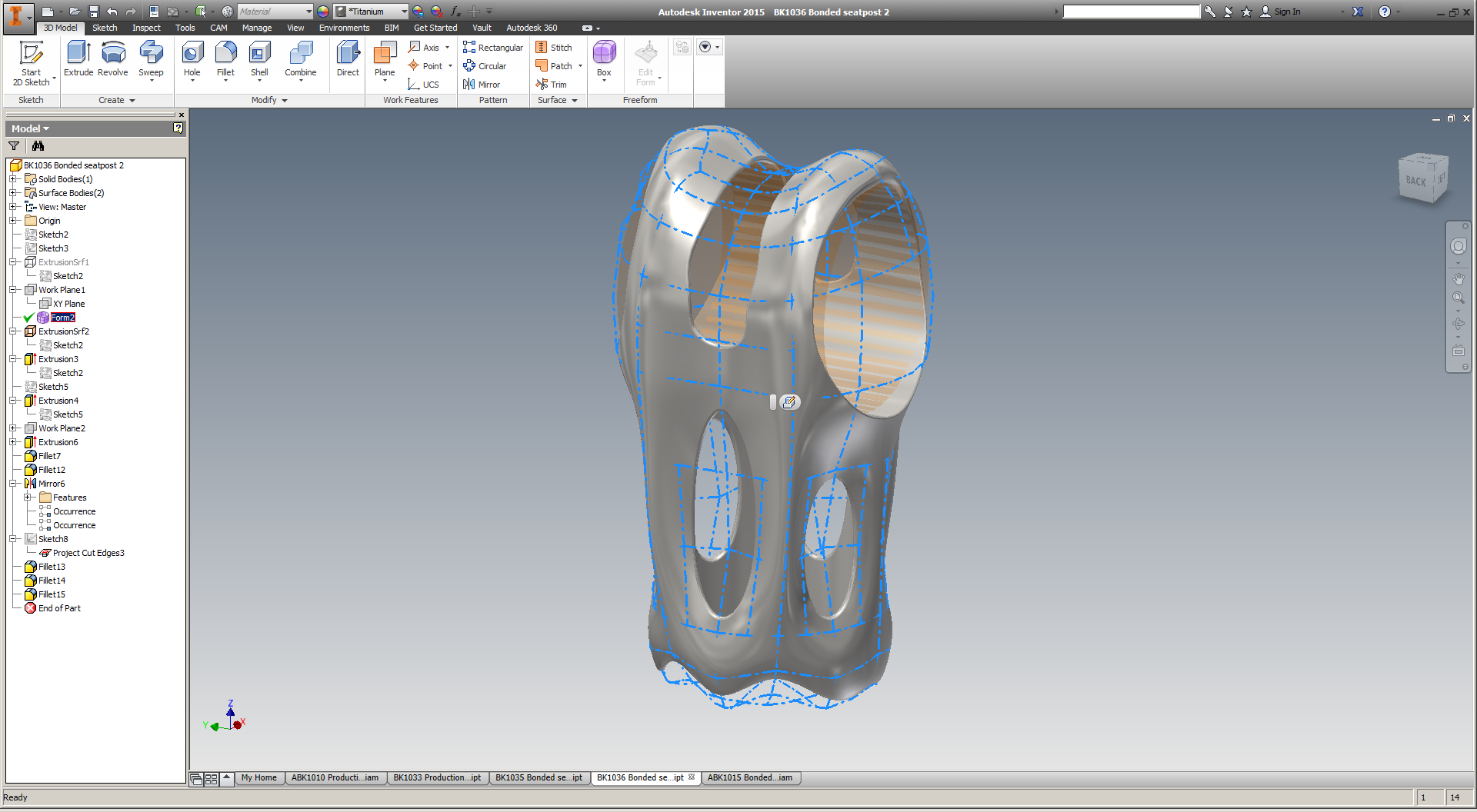

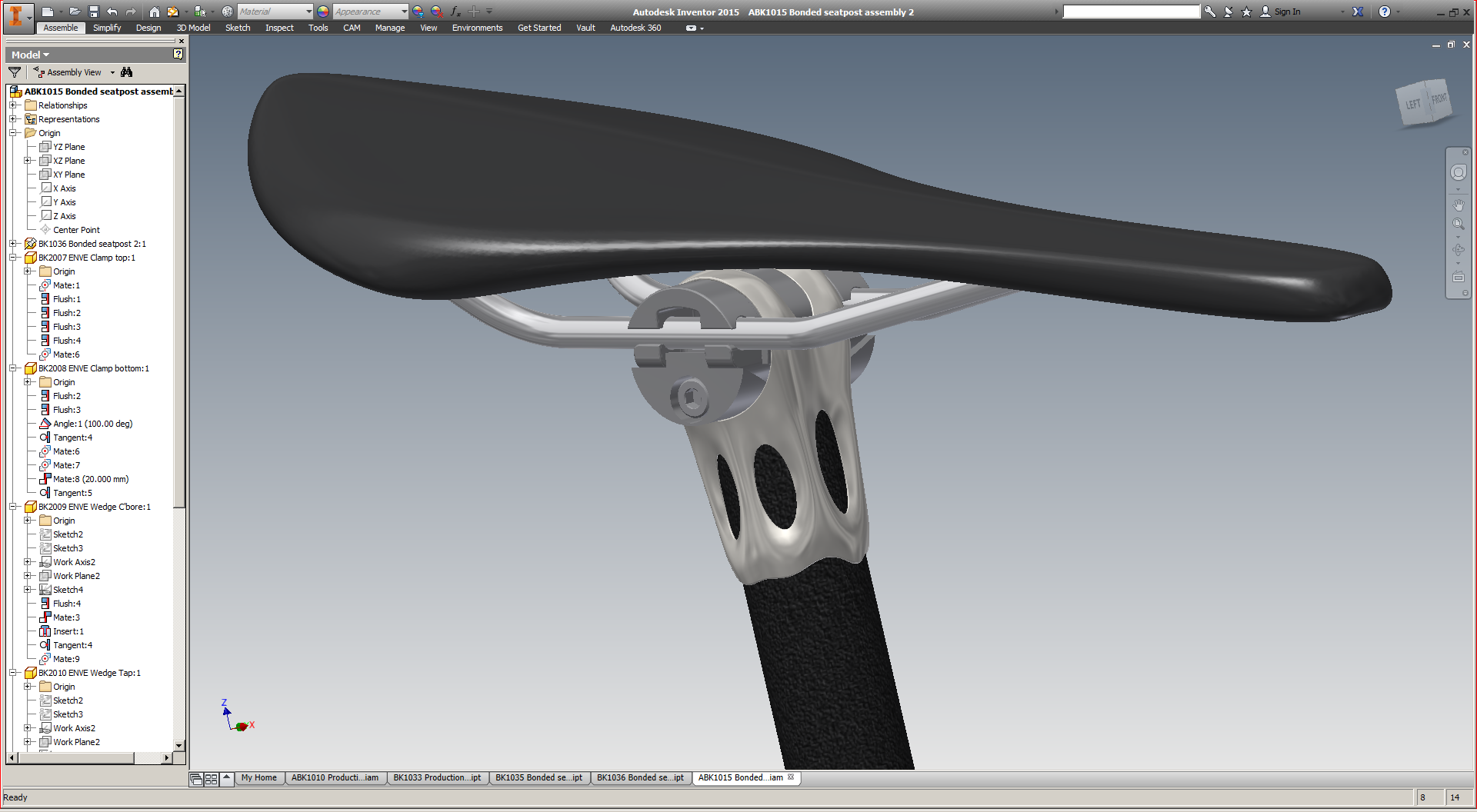

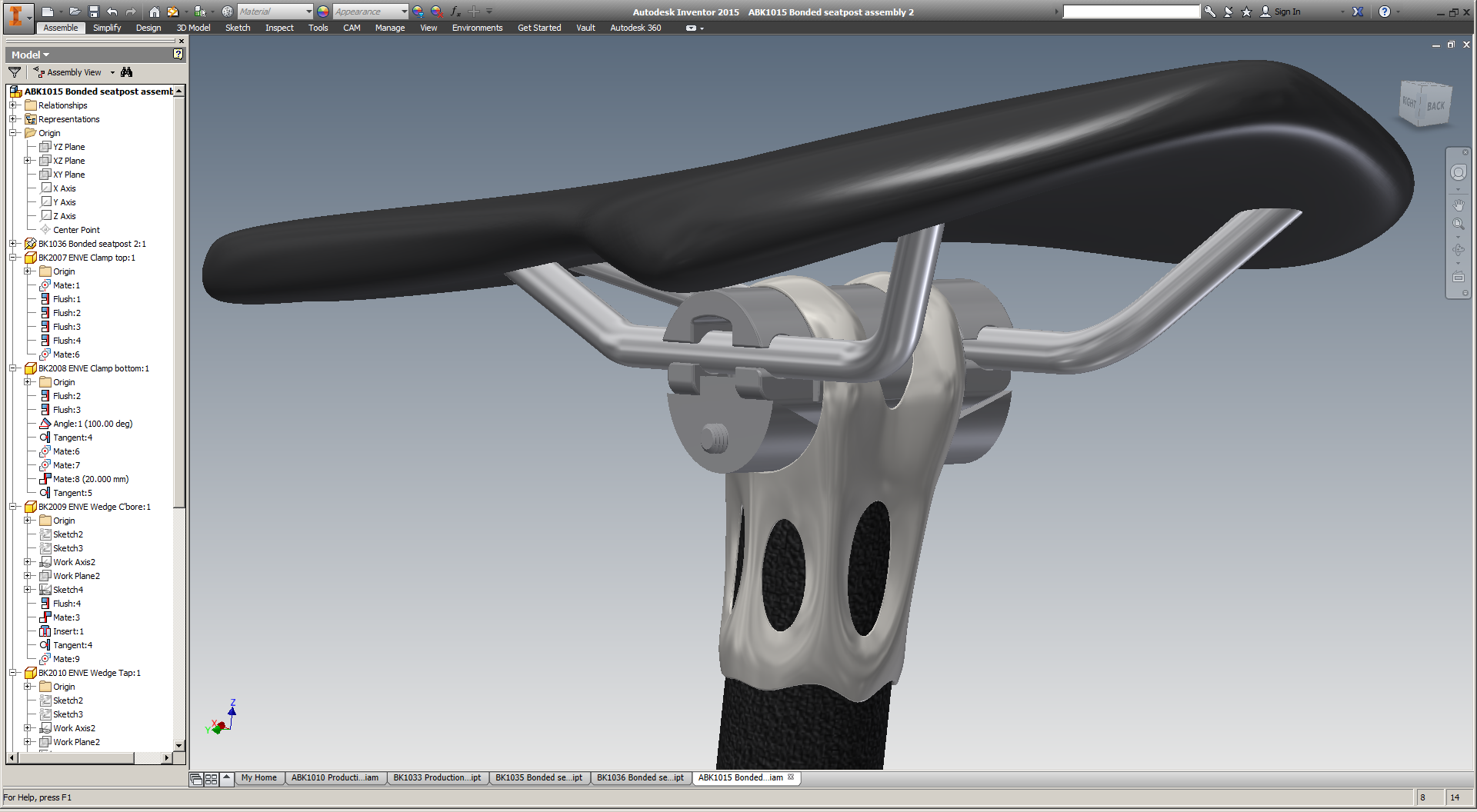

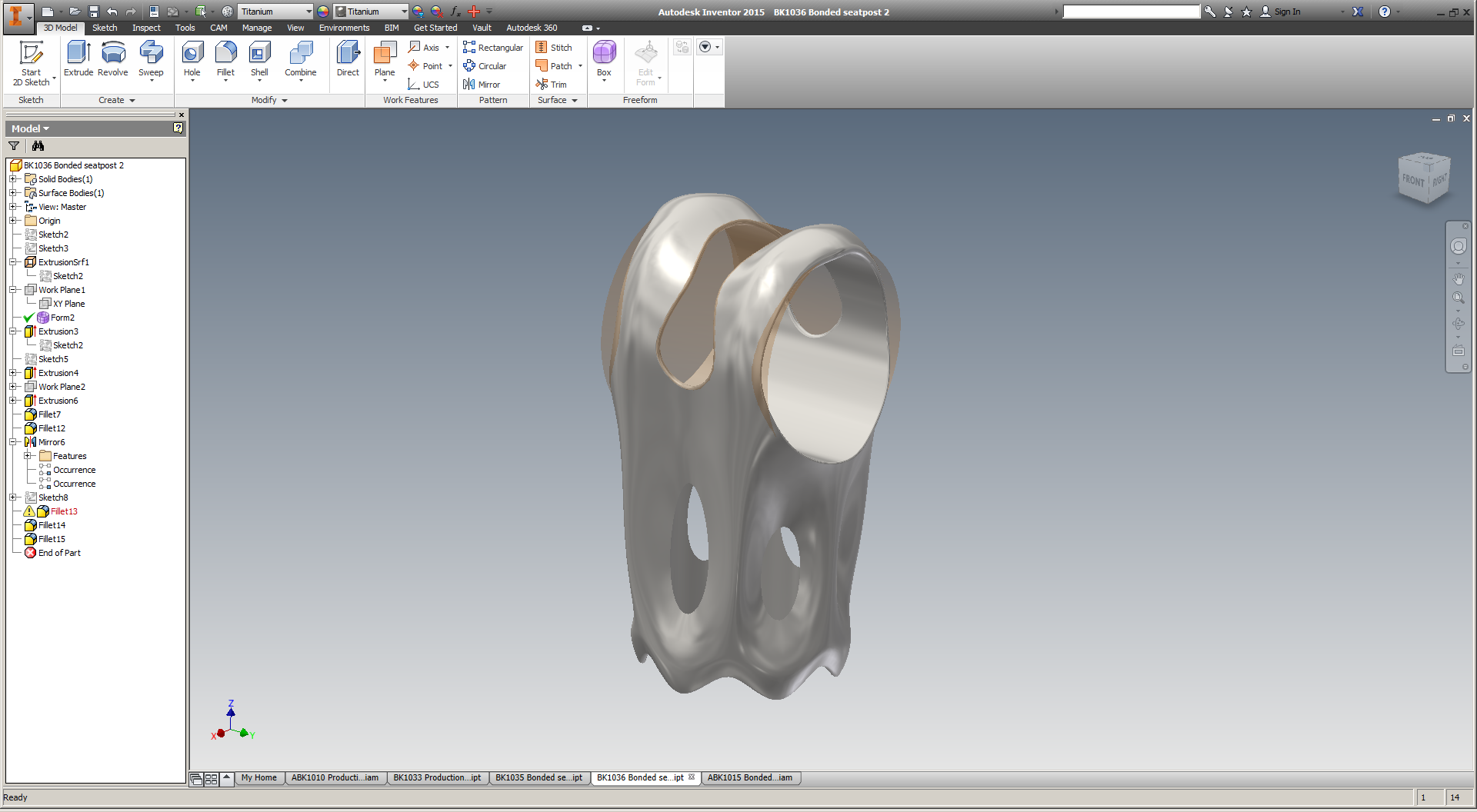

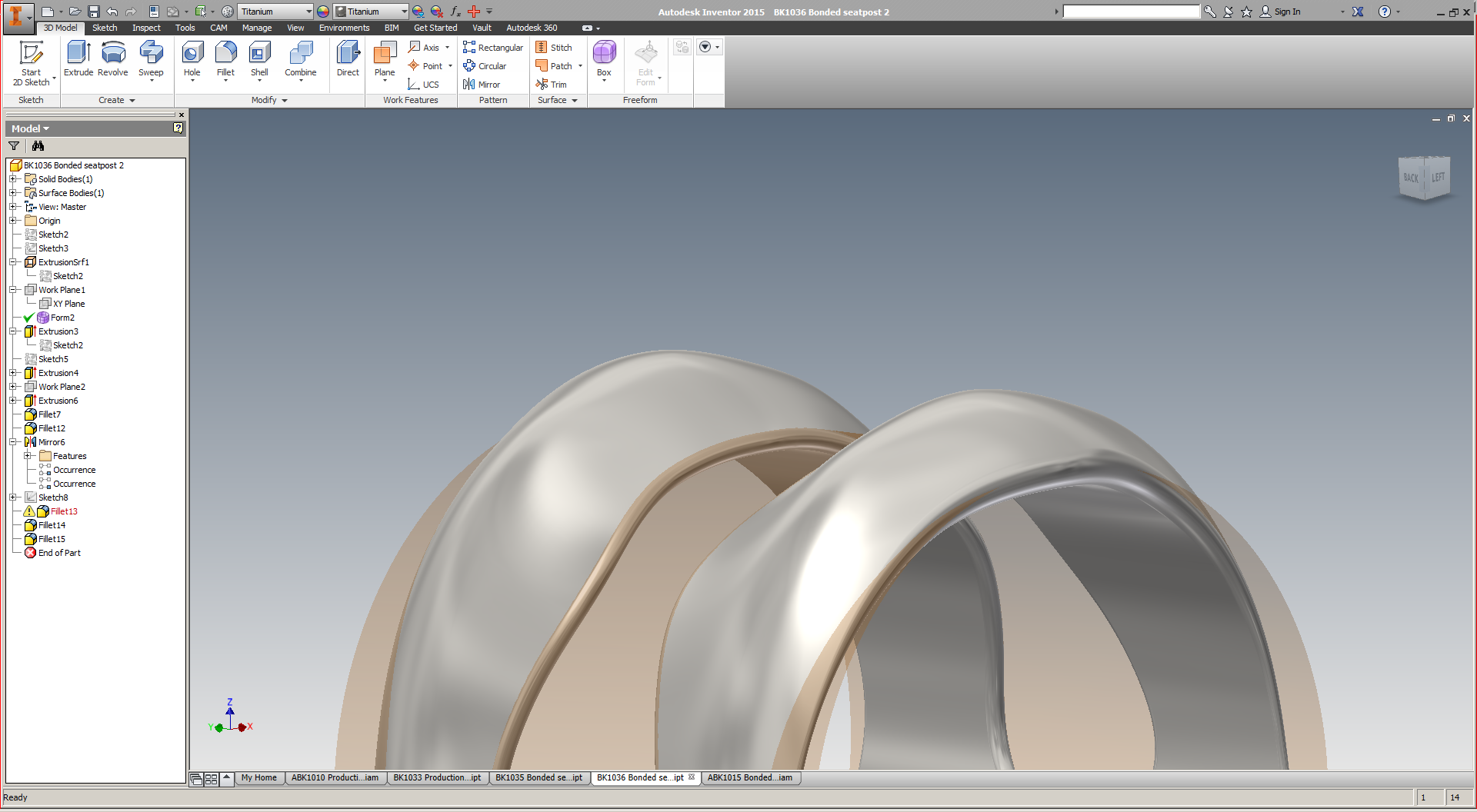

The part in question is the head of a seatpost assembly for high end road bikes. The part itself is small - about 70mm tall and with a 35mm square footprint. As built, it's just 32g of titanium 6/4. Add in a piece of carbon fiber tubing (88g for a 300mm length) and some rail clamp hardware (50g), and the entire seatpost assembly should be in the 175g range - on par with the lightest seatposts on the market today.

As a product manager who's ultimately optimizing for commercial viability, I had three questions going into this process:

- How do the costs of the different manufacturing process chains compare?

- How do the resulting parts compare functionally, i.e. in destructive testing?

- Functionality being equal, how do the aesthetics (and hence desirability) of the parts compare?

Towards these ends, Dr. Diaz and REM finished three parts for me:

The parts were printed in titanium 6/4 on an Arcam A2X by Addaero Manufacturing. They were then HIP'd (hot isostatic pressing is a whole other area of interest - more on it soon, I hope) before being treated by REM's isotropic superfinishing process.

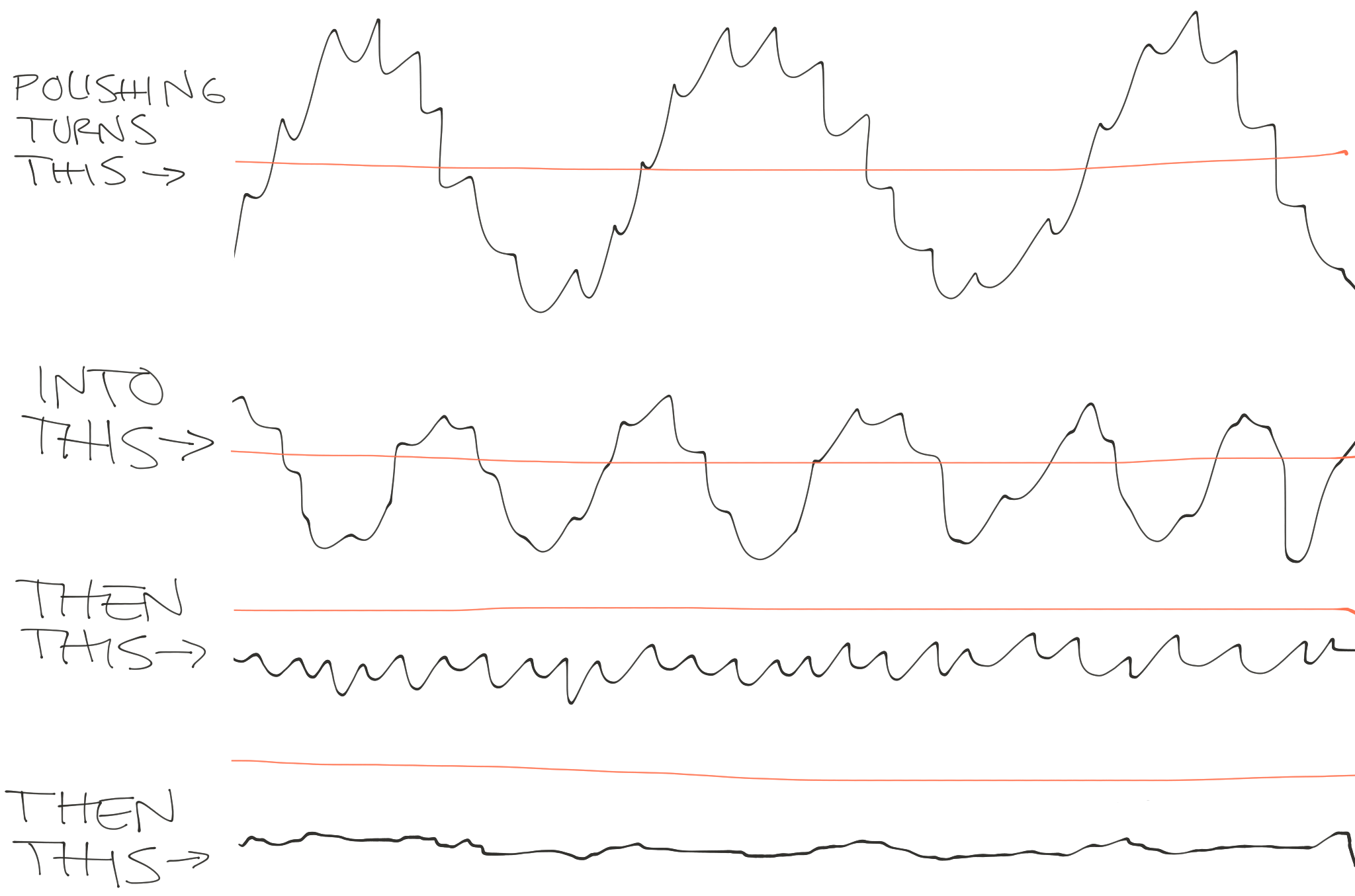

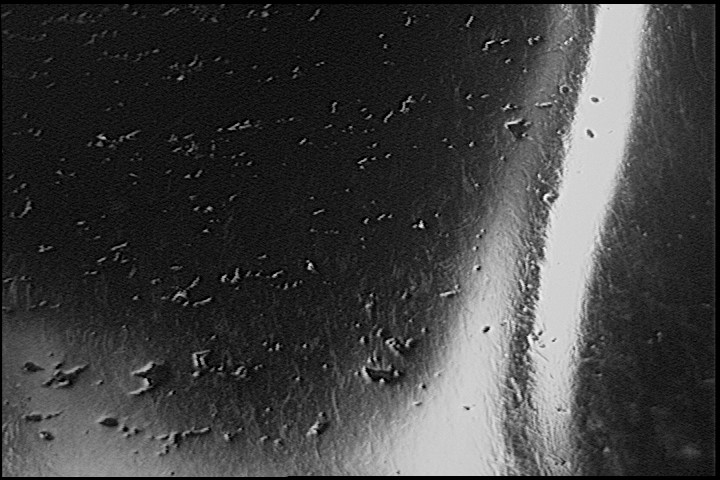

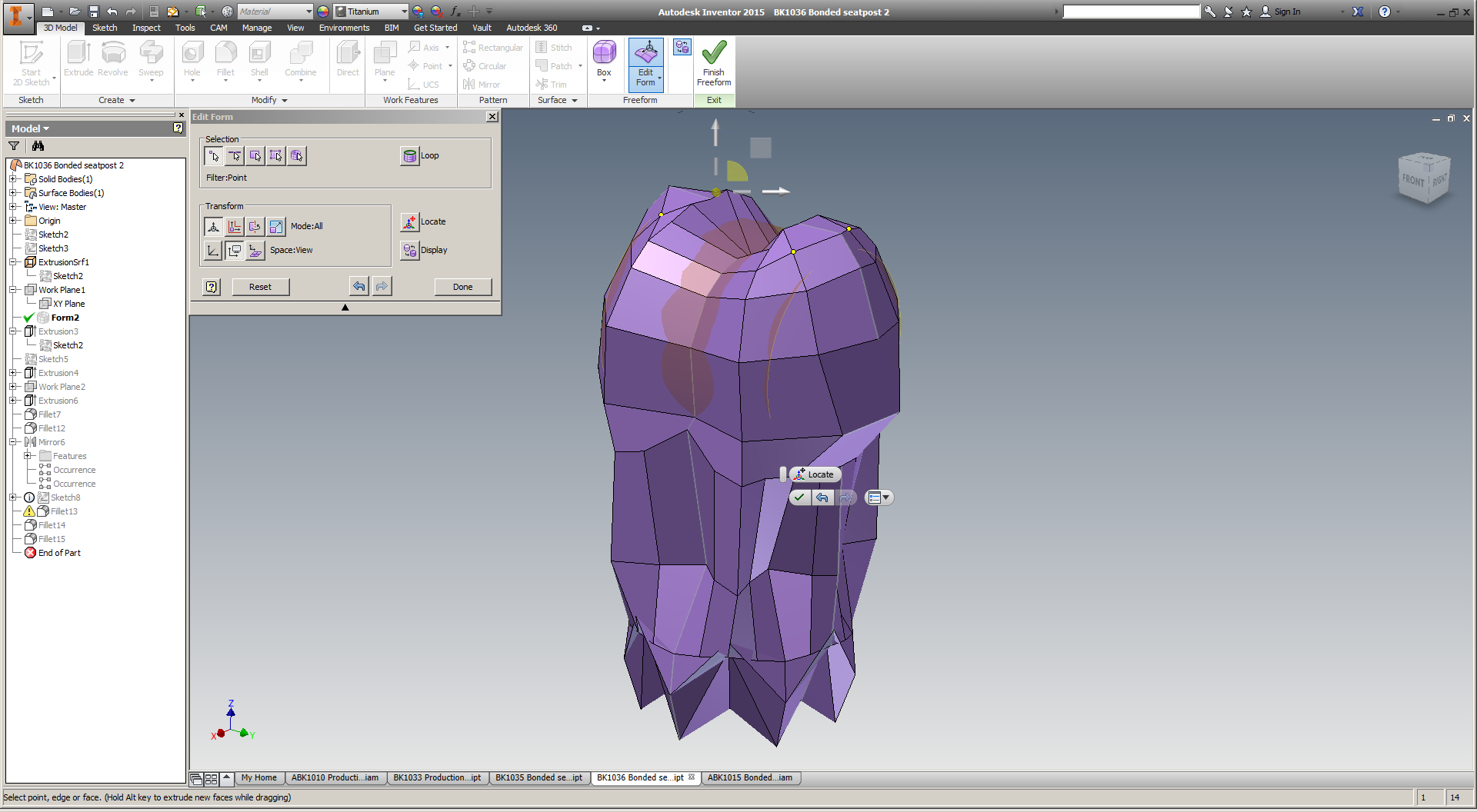

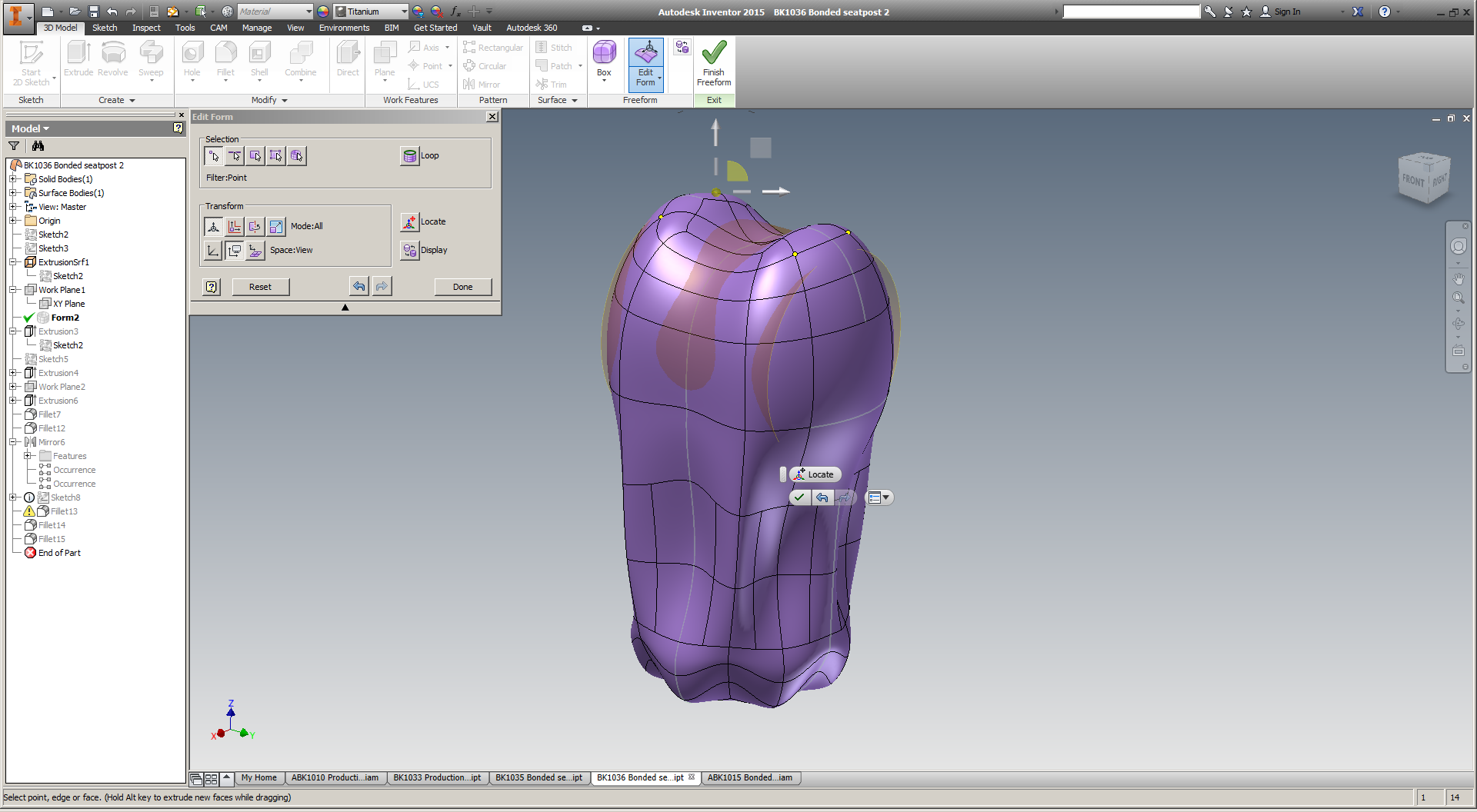

The results are very interesting, and contrast in many ways with MicroTek's MMP process. REM ISF is a chemical accelerated vibratory finishing process. In it, parts are placed in vibratory finishers with a nonabrasive media and a chemical activating agent. The chemical agents are selected by the part's composition: Different metal alloys will react to different chemicals. The media, on the other hand, is selected depending on the part's geometry: Parts with small features will require smaller media, etc.

As with any vibratory finishing process, then, REM tunes the frequency and amplitude of the machine to adjust the aggressiveness of material removal. The media chambers in these machines are shaped like toruses, and parts take a rotating helical path around them as they vibrate. Adjusting the frequency and amplitude of the vibration affects that helical path, and REM tunes the rolling angle to produce the result that's needed. "It's an art and a science," Dr. Dia zaddtold me.

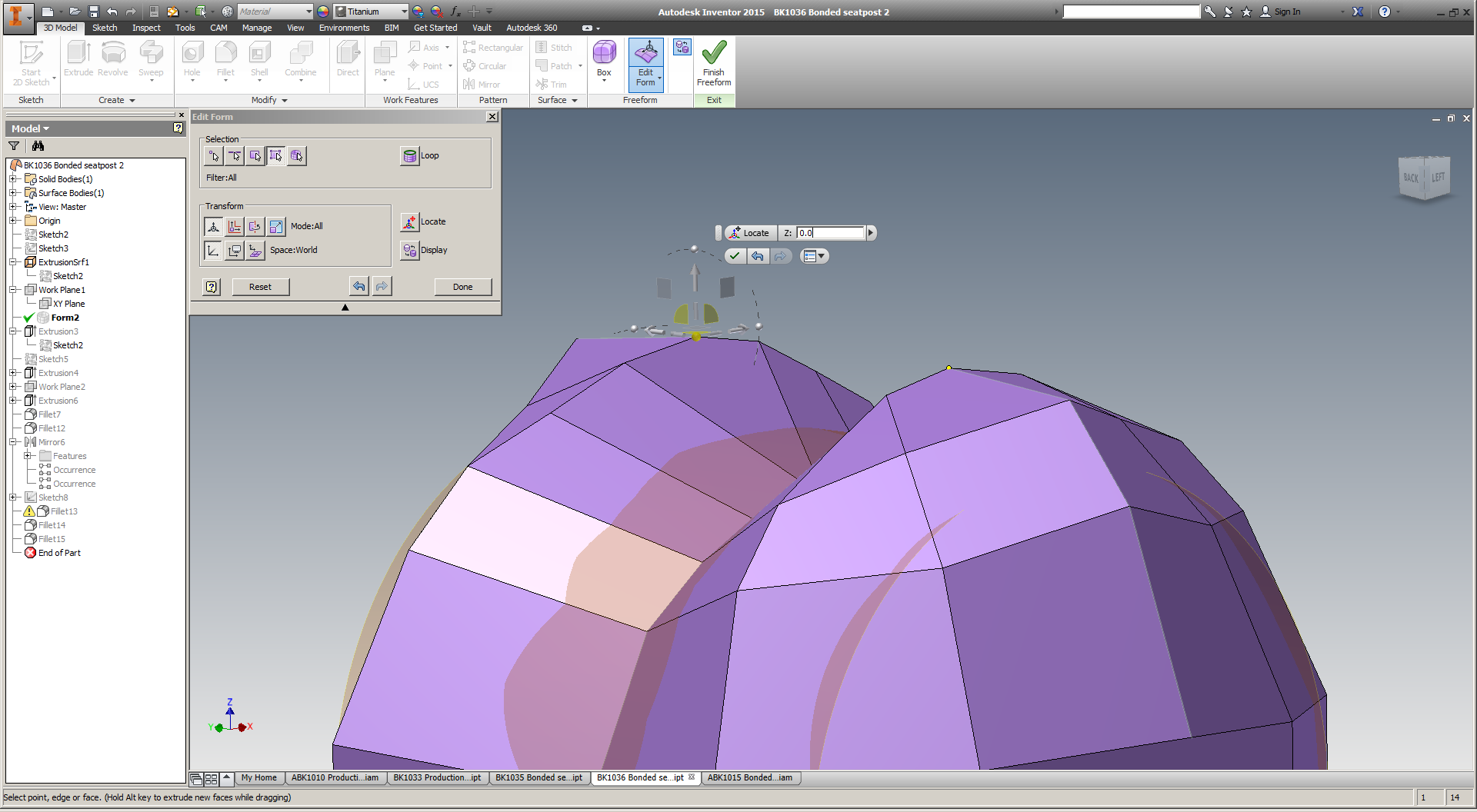

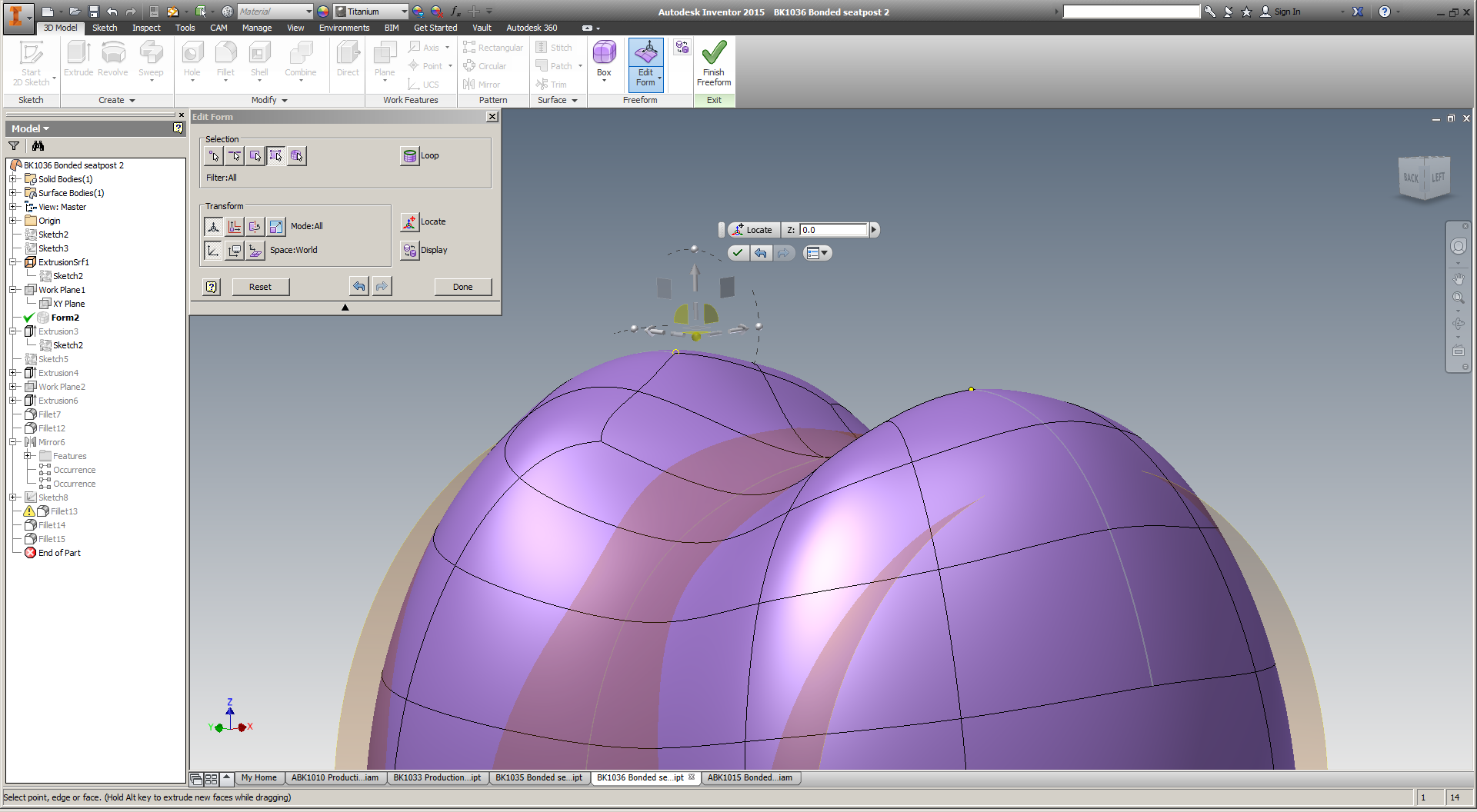

REM finished three parts for me, in two slightly different design variations. The first part went through their Extreme ISF process - a quick treatment that removes excess powder and some higher-order roughness. The second two parts went through Extreme ISF *and* an additional ISF treatment, removing .020" (about .5 mm) and producing a much smoother surface. In order to compensate for the material removal, one of the Extreme ISF + ISF parts was printed with .020" of extra stock on all of its surfaces (if you look closely, you can see the additional stock as a stair-stepping effect on the inside of the skirt edge). The results are below - click on the photos to enlarge.

Incidentally, I found REM's process nomenclature a bit confusing at first. As described above, all of these processes include some chemical agent and some media. The difference in the different processes has to do with the balance of those two factors: Extreme ISF uses aggressive chemistry but relatively little media interaction, whereas ISF is a longer process with less aggressive chemistry and more media interaction. REM also offers a Rapid ISF process, which is to ISF much as a lathe is to a milling machine. In it, the parts are fixtured and then moved through the chemical/media mixture. It's a much faster process, but one which requires more tooling and setup and hence is reserved for high volume parts.

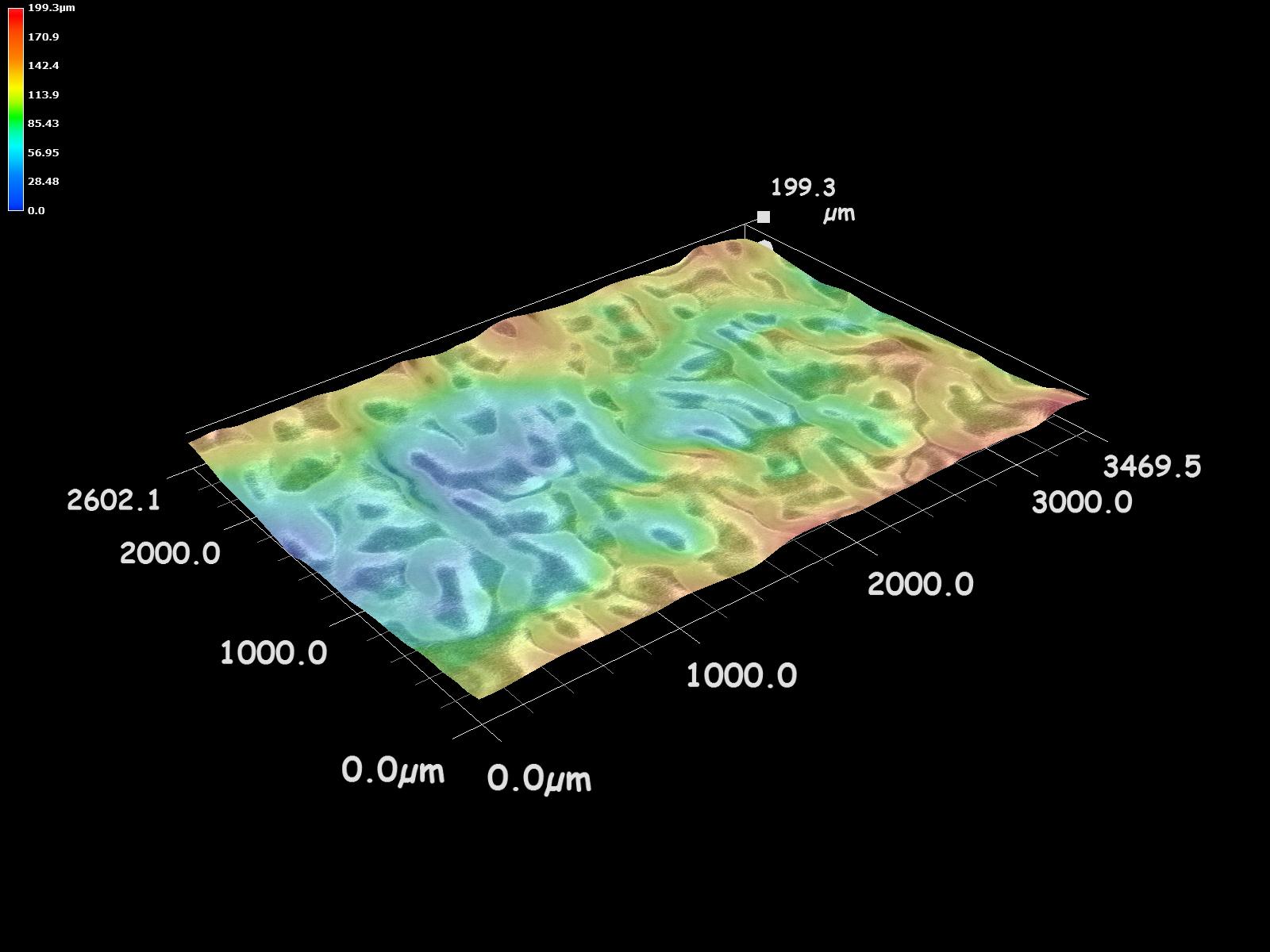

The surface character of the REM parts differs significantly from the parts that I had MMP'd. ISF interacts with the full surface of the part, with the result being that both peaks and valleys are rounded out. Note that the color scale in the images below are not constant; click on the images to see the color scale key.

The roughness values for the two methods are also quite different. The key metrics are below; full roughness profiles & filter data are here for Untreated, Extreme ISF, and Extreme ISF + ISF parts (thanks to REM).

Ra - Roughness average

Rq - Roughness, root mean square

Rsk - Roughness skewness

Rt - Roughness total

As with most things, the numbers above both a) capture interesting differences between these five finishing methods, and b) are abstractions which ultimately fail to capture the entirety of the physical parts. Such is the nature of data; in and of itself, it's not particularly insightful.

As I've described previously (and above), my interests are functional, aesthetic, and economical. The latter two of these sit more or less in balance, but the former is bound by the composition & arrangement of matter. To that point, Agustin referred me to a paper by Kwai Chan called "Characterization and analysis of surface notches on Ti-alloy plates fabricated by additive manufacturing techniques," which shows a correlation between notch depth and a shortened fatigue life in EBM parts. To quote:

The presence of surface notches is likely to promote crack initiation and reduce the fatigue performance of LBM and EBM materials. Since the depths of the surface notches correspond to the maximum valley depths on the surface, fatigue life of the various Ti–6Al-4V materials is expected to decrease with increasing maximum Rvm values...

To improve fatigue performance, the surface notches on the EBM and LBM materials must be removed by machining.

Of course, those last two words - "by machining" kind of begs the core question that I'm asking here. To wit, see the Rvm numbers from REM:

Rvm - Maximum valley depth

The goal, here, is to improve fatigue life - and avoid the fate that my last parts met during testing. My hope - and one that's balanced by my lingering concerns about my glue joint design - is that the much reduced Rvm numbers here will help significantly.

More soon.