I’ve been working a lot on the mechanics of how Gemba (my idea for a shared industrial 3D printing space in NYC) would work, and it struck me that I should probably write down why I want to do this in the first place. These are intended to be mostly personal reasons; here goes.

I like building stuff. Having a measurable output is a big motivator for me, and I find myself similarly drawn to people who are building stuff too.

In particular, I like building stuff that’s valuable. I’m being intentionally abstract here: my blog is valuable, and so are manufactured goods, and so is the process and craft that one learns by manufacturing things, and so is the management expertise that one develops through years of working on hard problems, and so is the social capital that one accrues by being a considerate, dedicated, hardworking person. Ideally, I’d structure my life such that I can focus on one of these things and still let the others flourish; the compound value would be exponential.

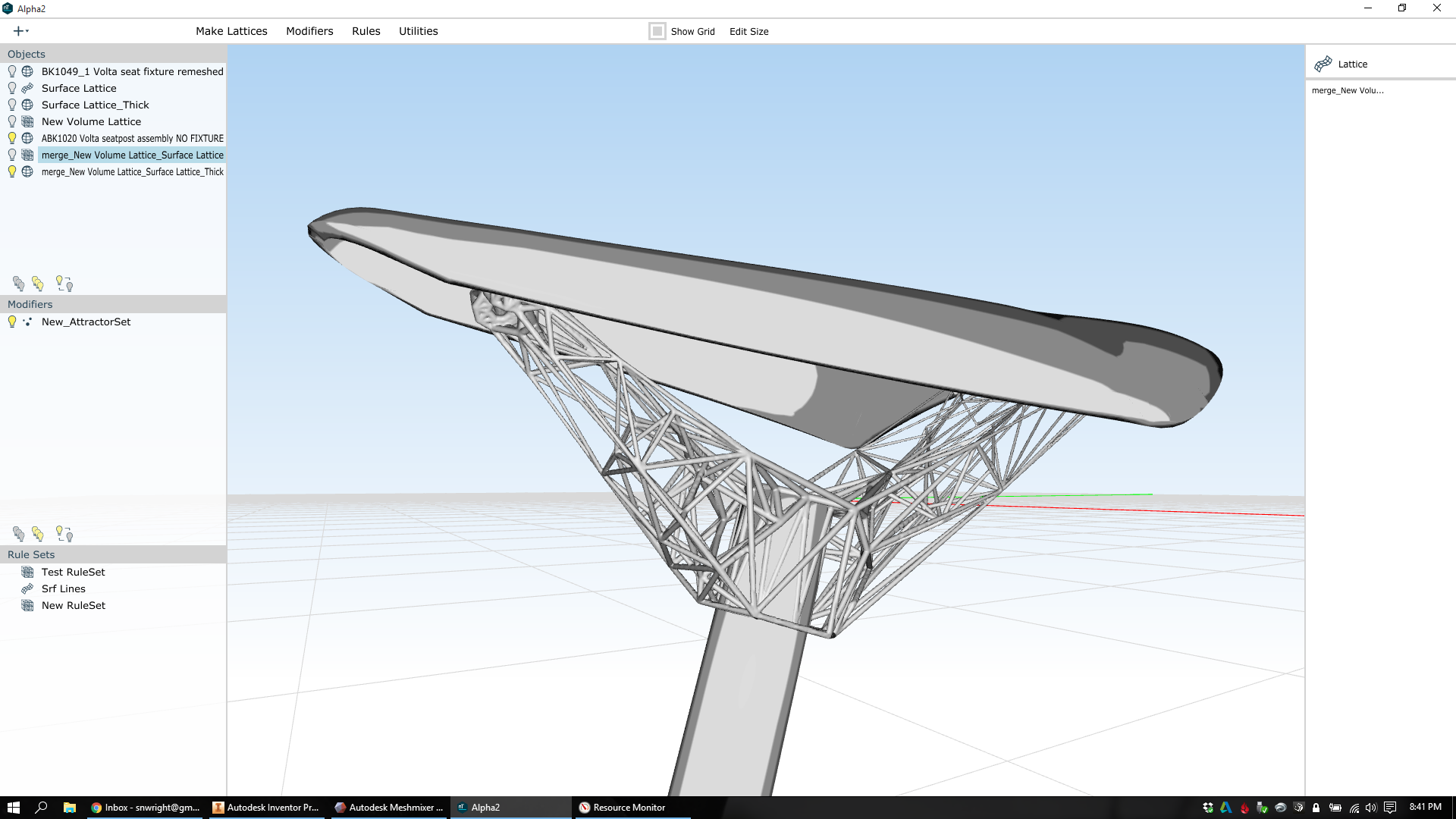

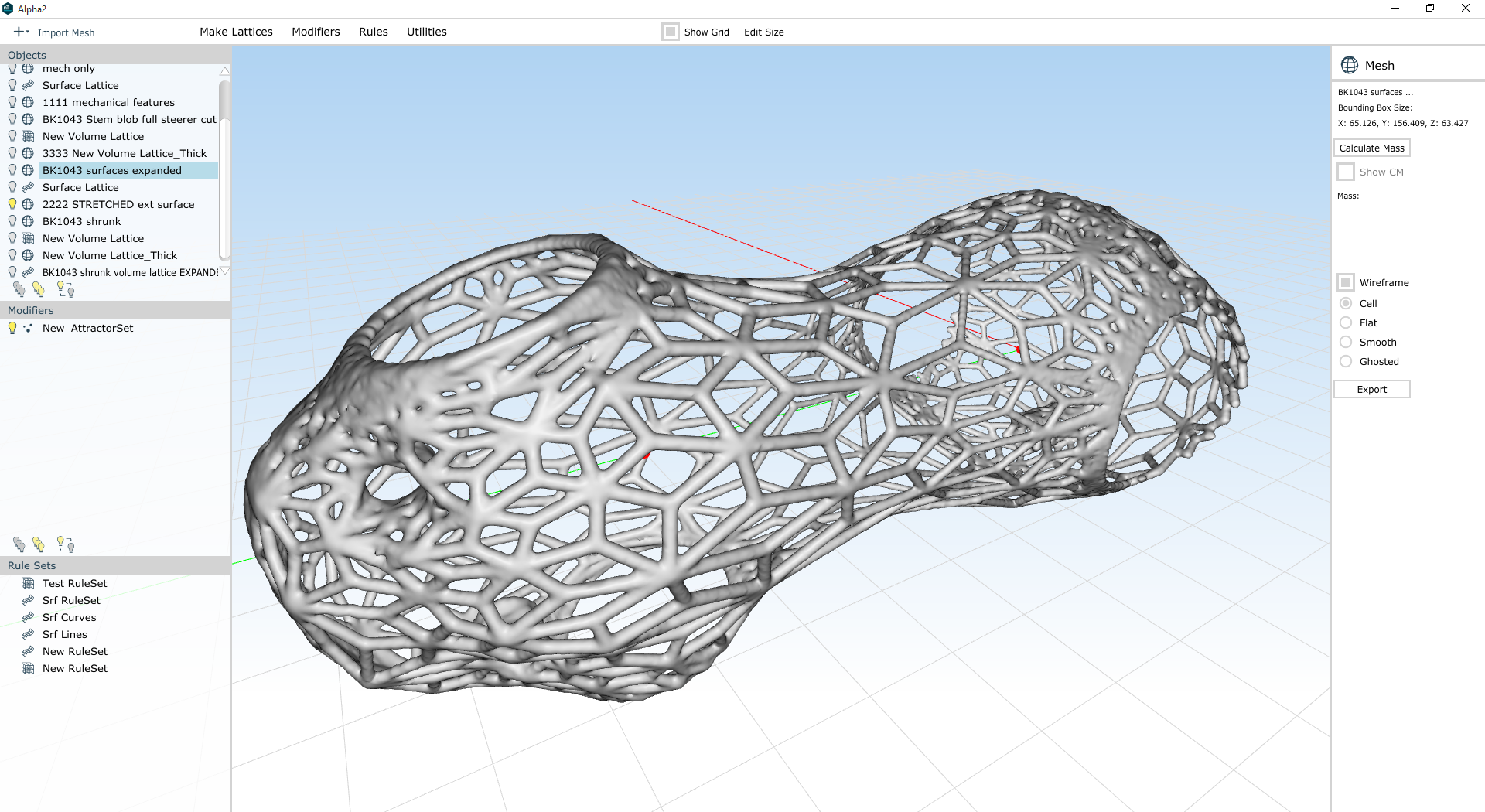

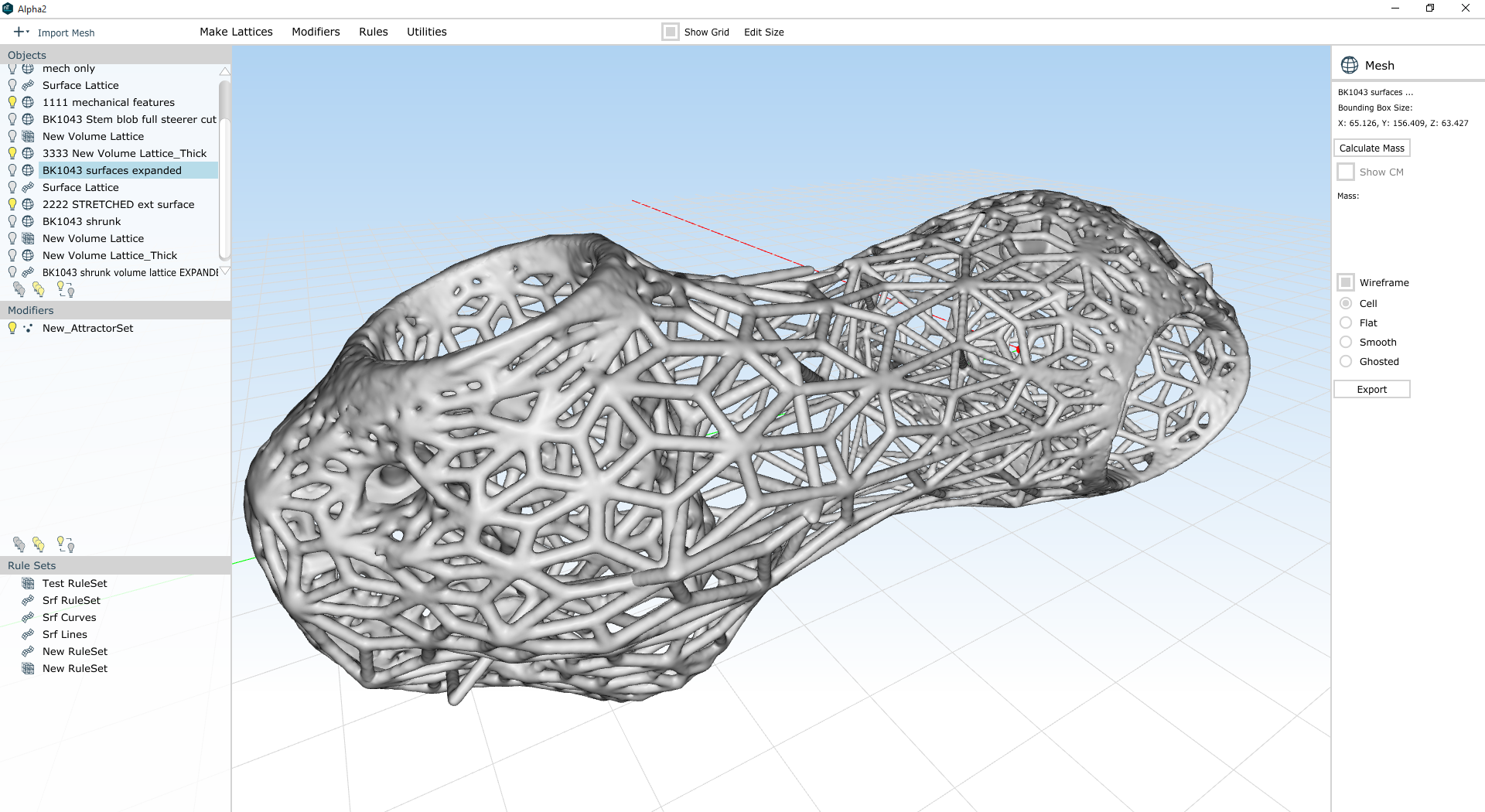

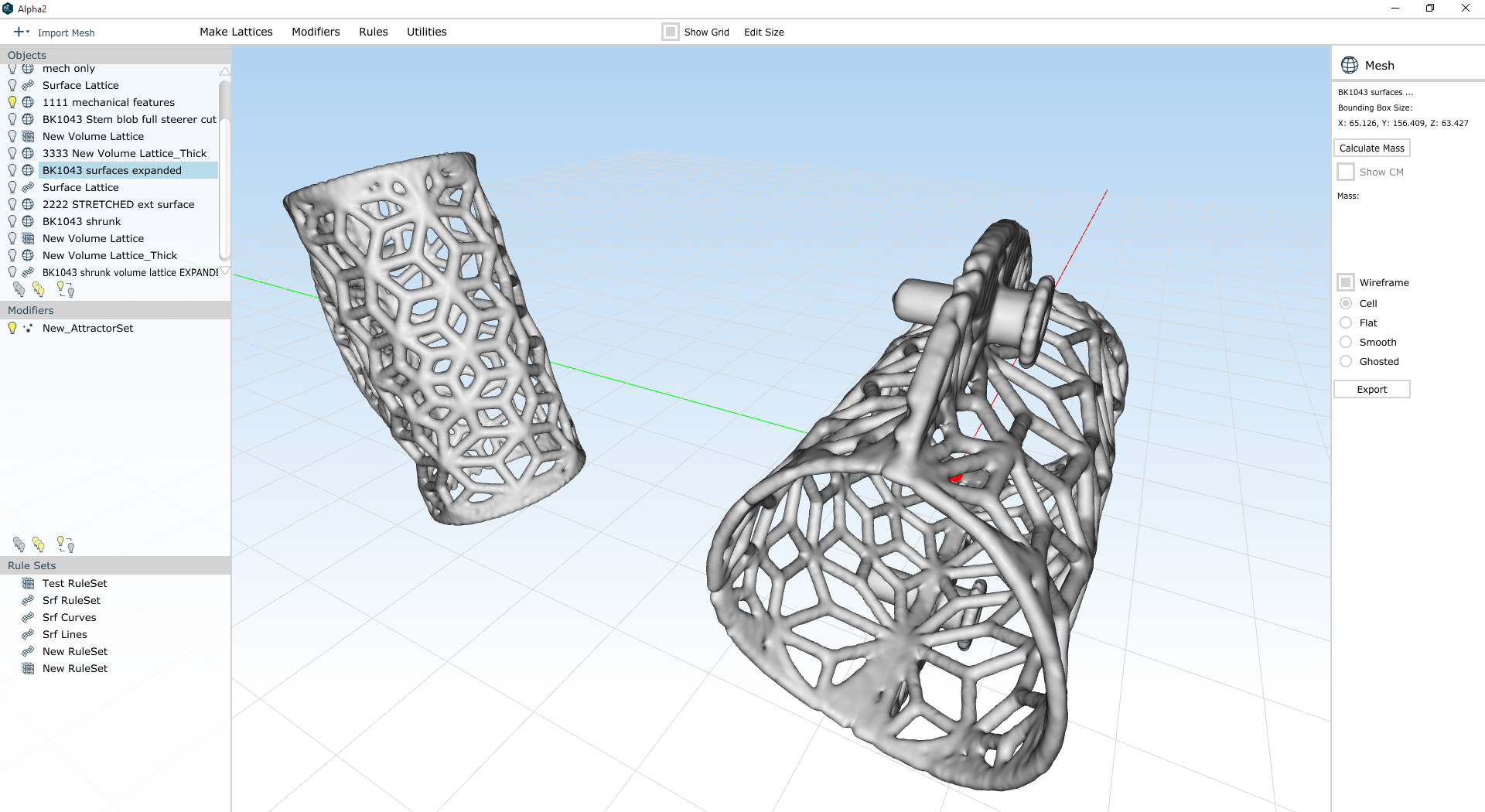

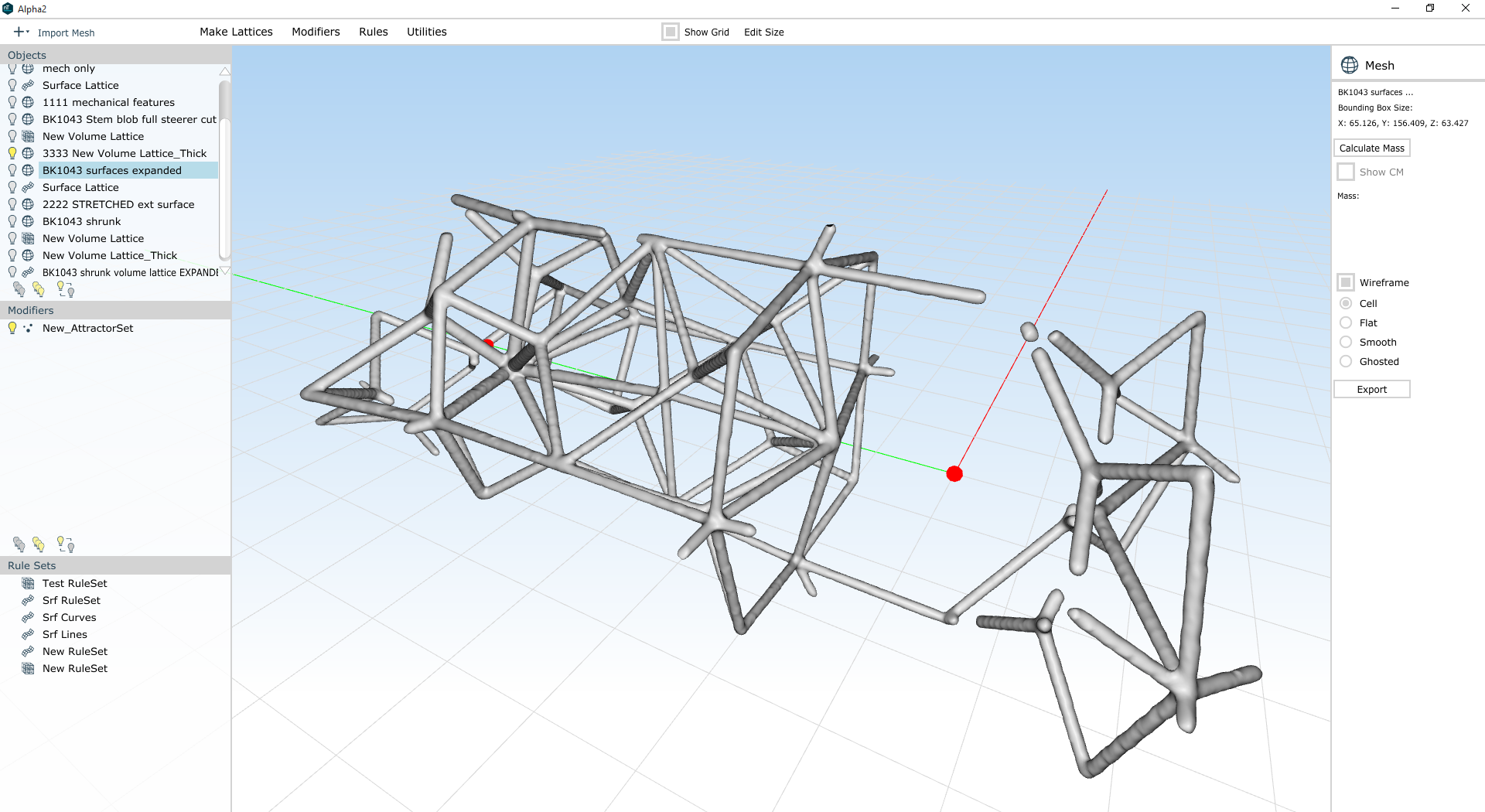

I also, for purely selfish reasons, want to make an impact on long term global problems. Like any new manufacturing method, I believe that metal AM has the potential to make a positive impact on our ability to make long term valuable products (lightweight transportation systems, patient specific orthopedic implants, etc) more effectively and efficiently. And given my experiences over the past two years, I think I can play a significant role in increasing its rate of adoption and maturity.

It’s possible I could do this in a private environment - working full time on a single, proprietary solution. But in order to create a larger impact more quickly, I feel it’s important to work alongside others. I want to work in the MIT Building 20 of advanced manufacturing. I believe that my own output - and my quality of life - will be much improved as a result.

It’s no secret that New York City is no longer the center of manufacturing that it once was. But at the same time we’ve got some of the nation’s top minds in architecture, engineering, and construction, and our 3D printing community is one of the largest in the world. We’re also the geographic center of a huge network of manufacturers (large and small) that populate the I95 corridor, and we remain *the* cultural magnet for young engineers graduating from any of the top tier schools in the Northeast.

These factors - and the anecdotal evidence that myself, and people like me, want a place to work on industrial grade problems - will give Gemba NYC a robust technical pipeline and talent pool. In addition, though, New York adds a significant edge when it comes to business model and marketing leadership. We (and by we I mean a combination of companies like Makerbot and GE) have been at the forefront of a total rebranding of additive manufacturing - one which has brought a huge influx of investment, talent, and ideas. New York also has a proven track record in developing and launching just in time, direct to consumer businesses (see Warby Parker, Casper, Blue Apron, etc) that shorten supply chains and are more responsive to end user needs. Additive manufacturing will need this expertise; New York will provide it.

In short: I believe in the technology; I believe in the power of working in close proximity with others in the industry; I believe in New York City’s ability to lead technical and commercial solutions to the problems facing industrial AM.

I want to increase the success rate of industrial additive manufacturing. I think it’ll be fun, and interesting, and will benefit both myself and humanity as a whole. And in order to increase my own success rate, I want create a space where dedicated, forward thinking companies and individuals can experiment with and develop solutions to the problems facing AM today.

This will require a big effort, and I’ll need the involvement of people and companies much more experienced than myself. I’m looking forward to hearing what their interests are, and developing a space and financial model that serves us all well. If the things above resonate with you, get in touch - I’d love to chat.