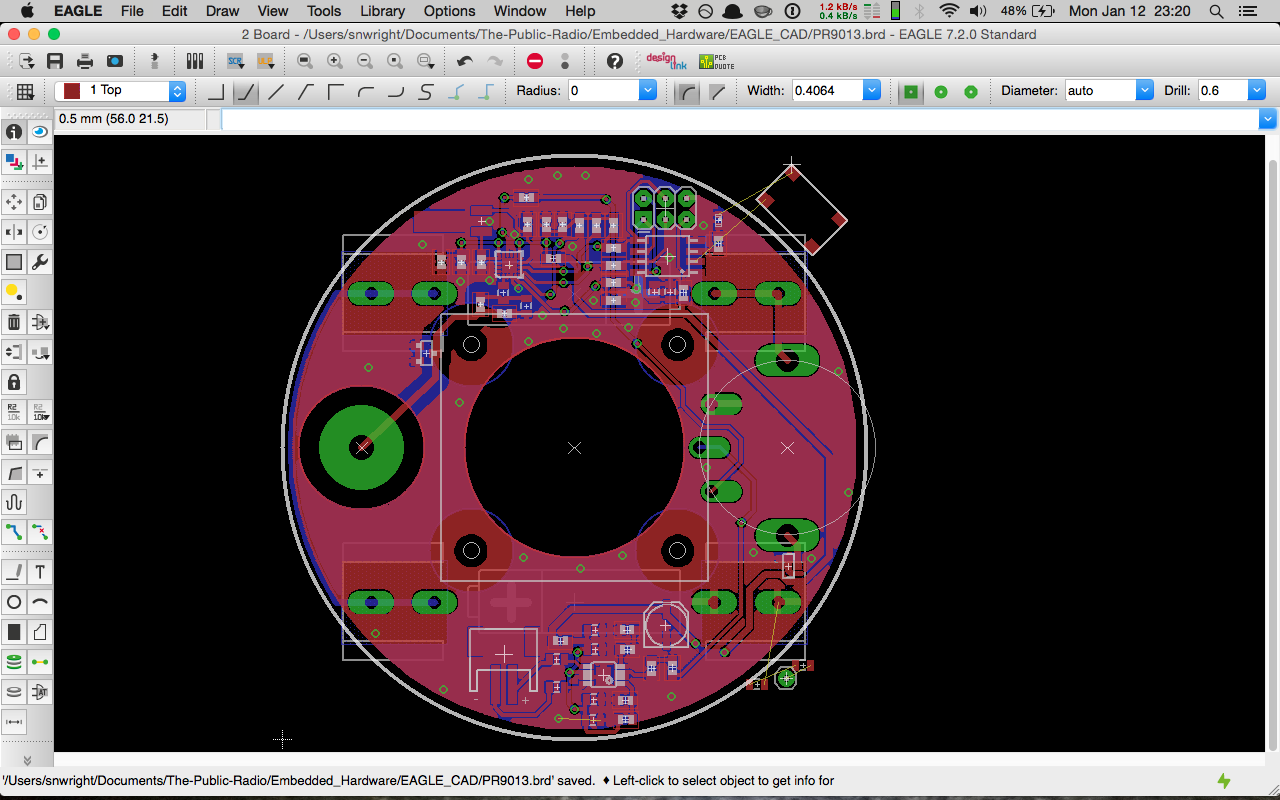

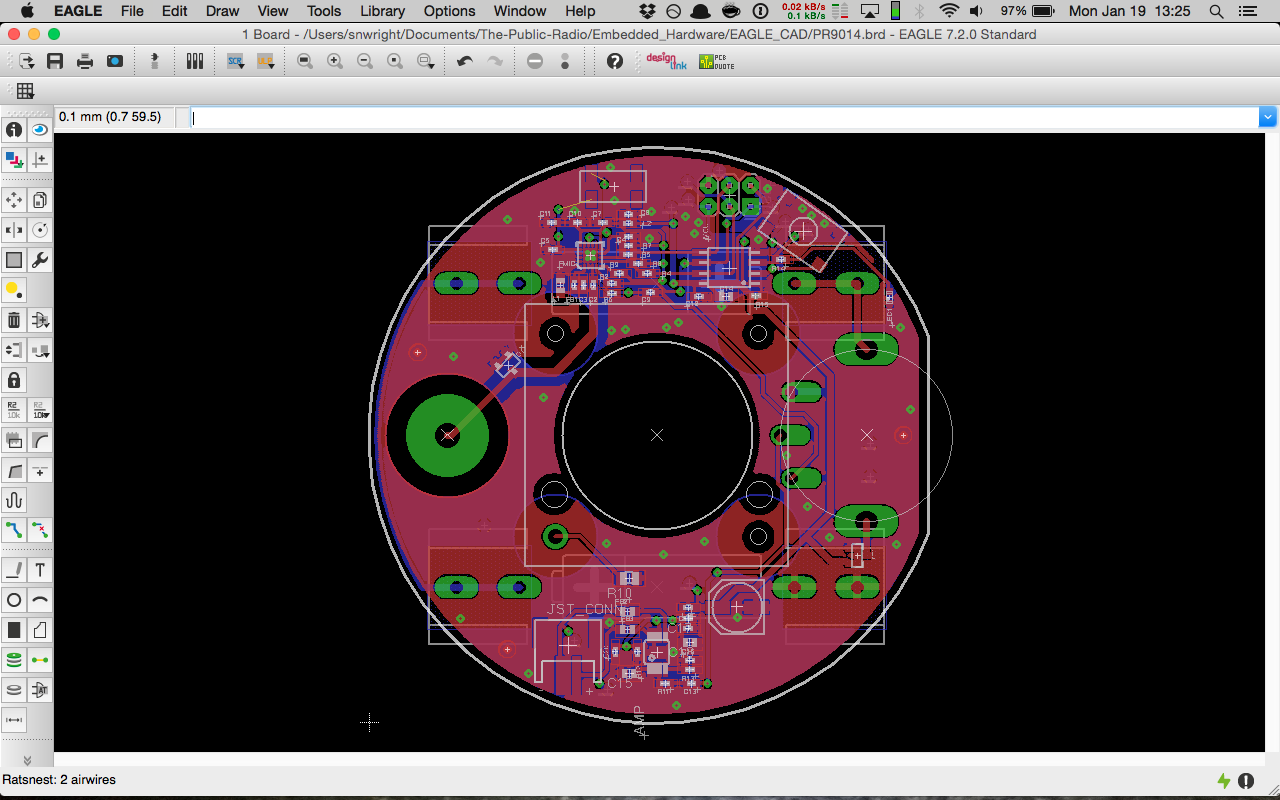

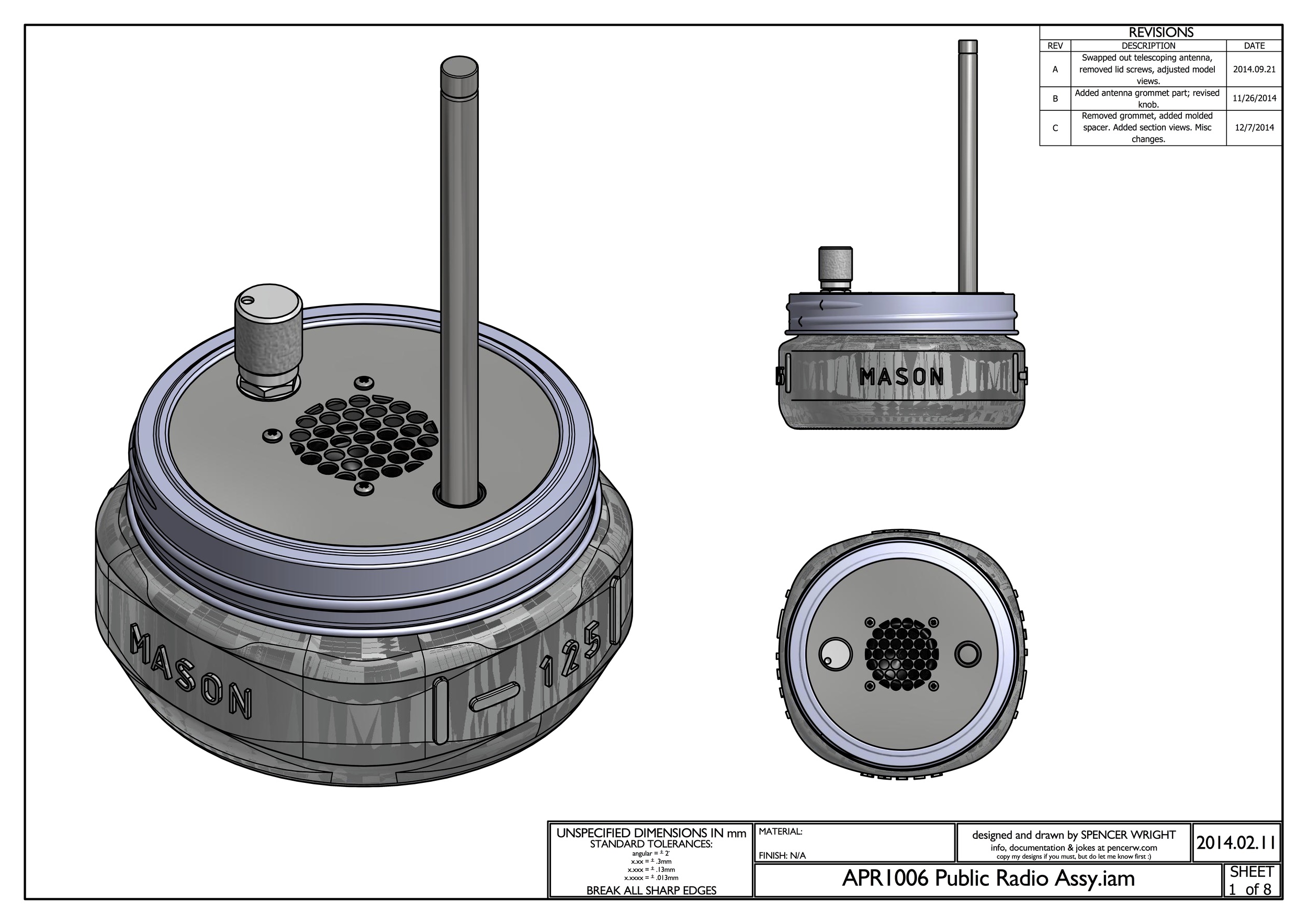

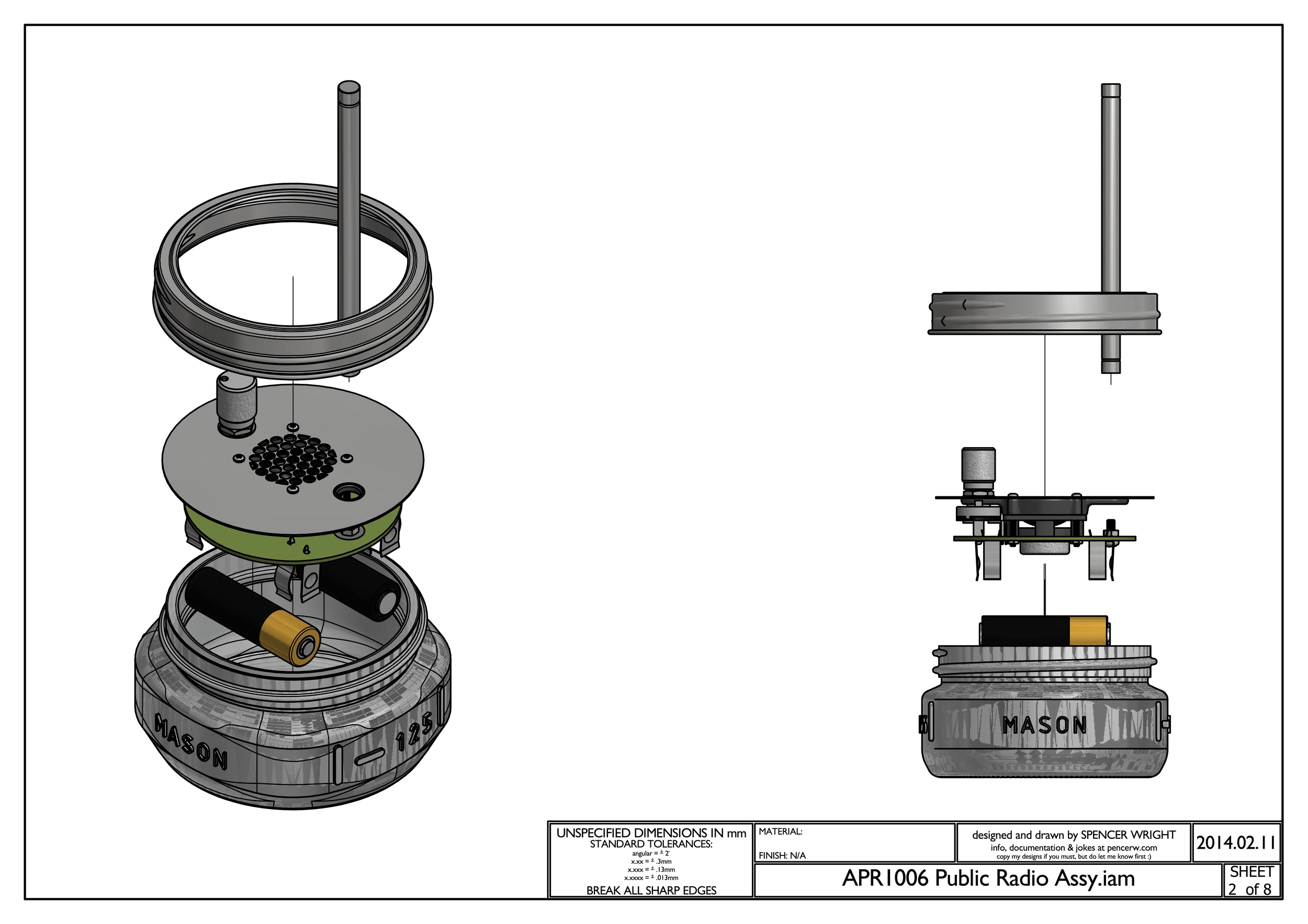

So, a few things have happened.

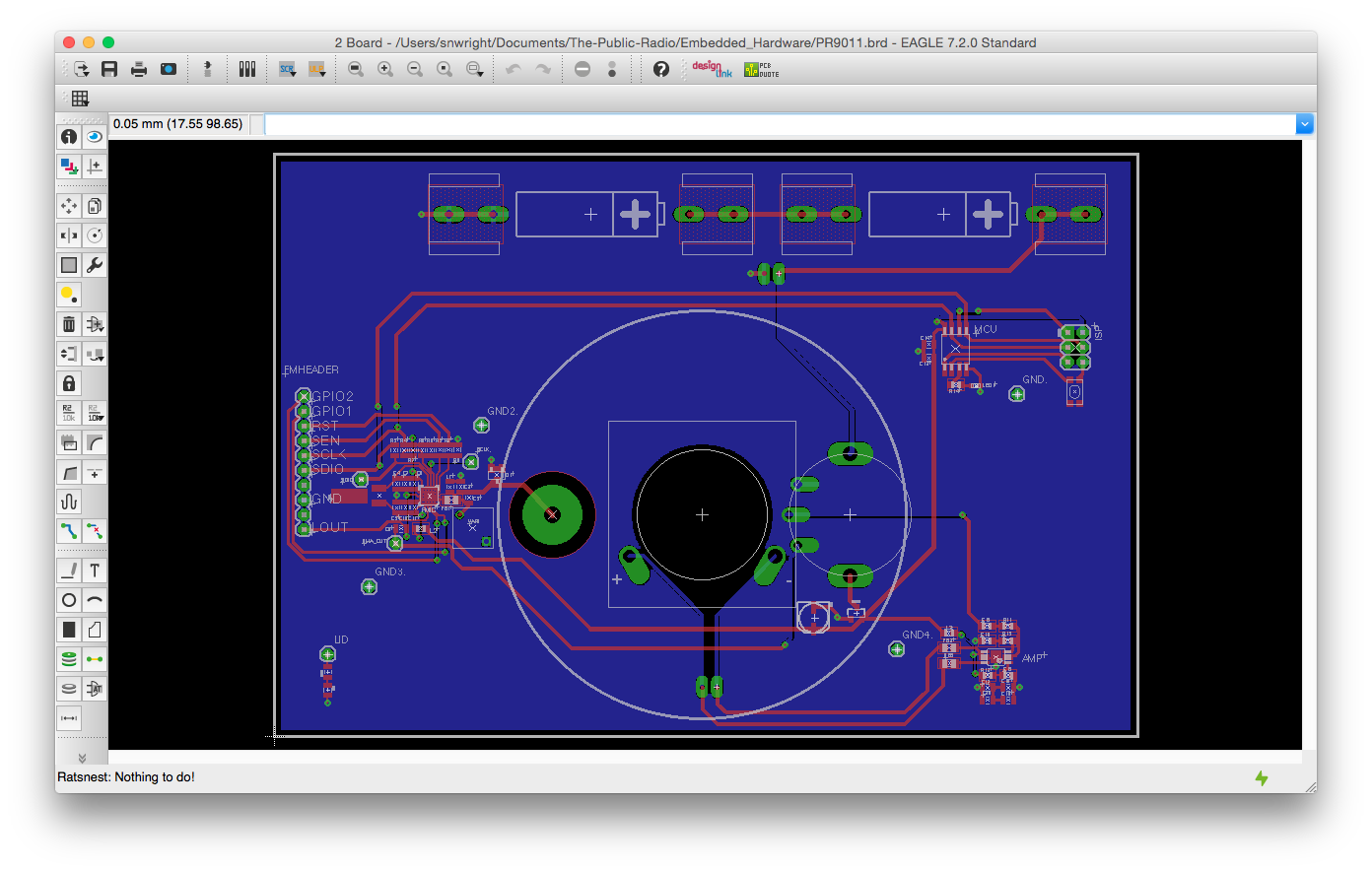

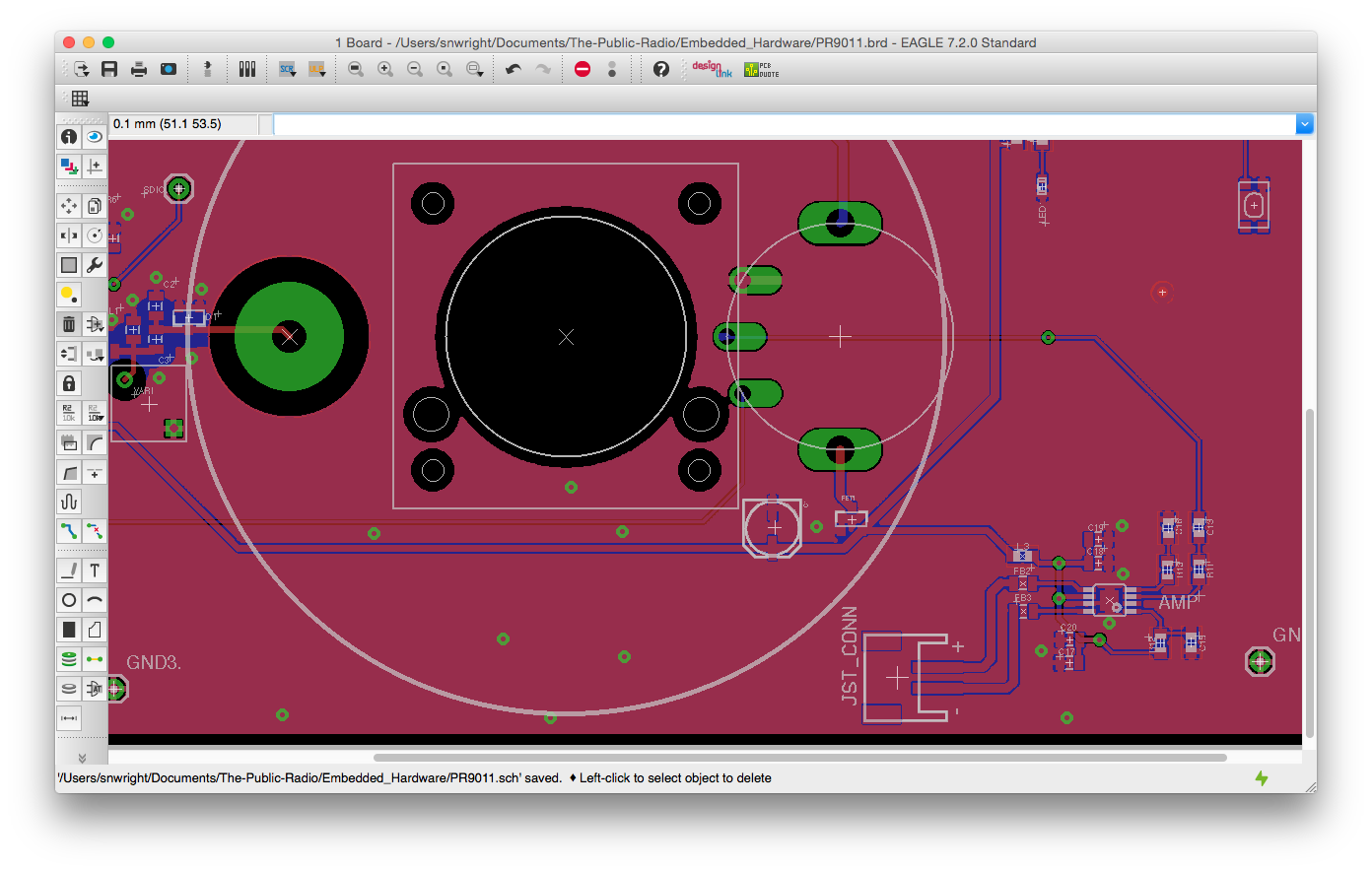

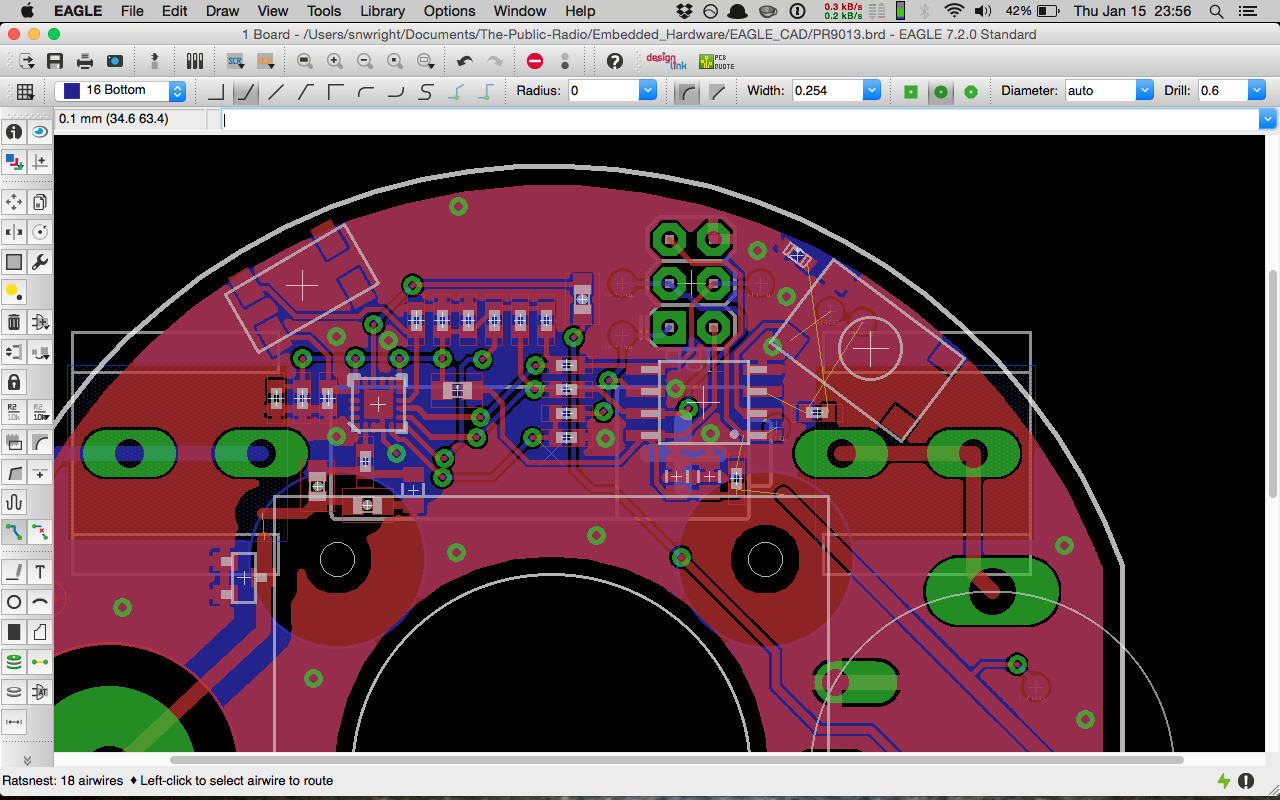

Over the past months, we've worked a ton on improving The Public Radio's reception. We want it to perform as well as any FM receiver on the market, but we were having trouble getting there.

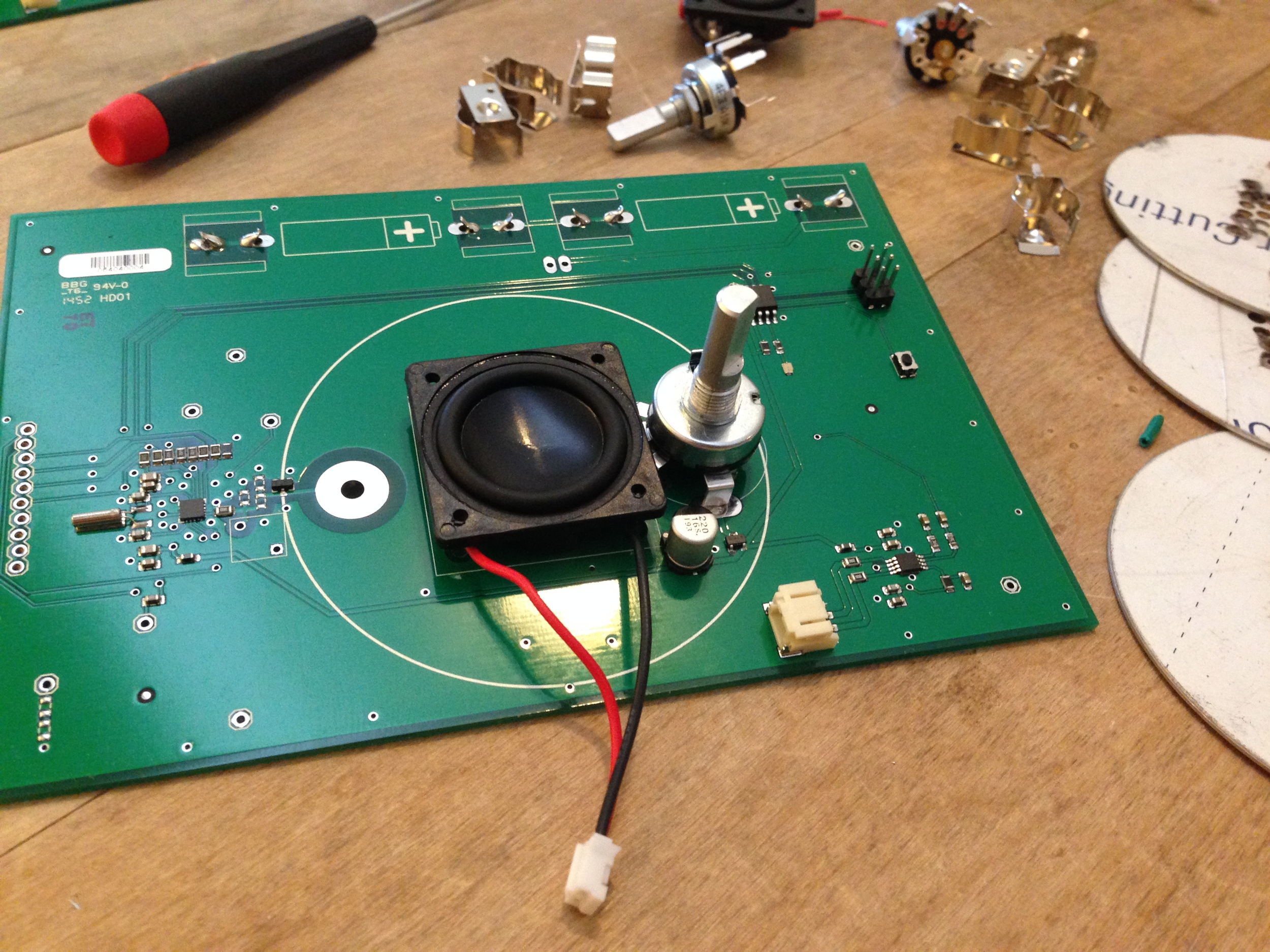

Finally, we spent a day with Todd taking The Public Radio apart piece by piece. And as it turns out, reception wasn't our issue - interference was.

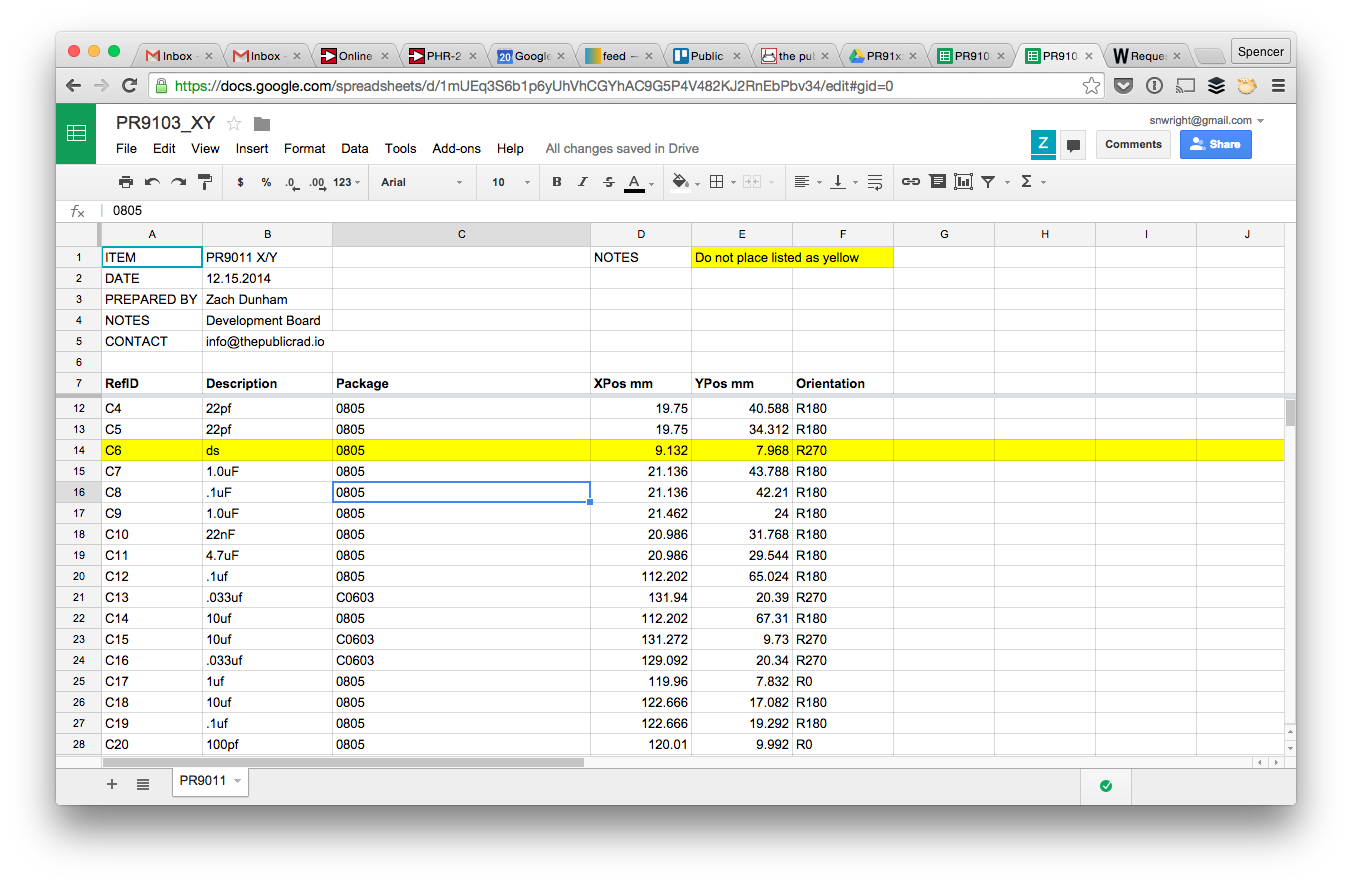

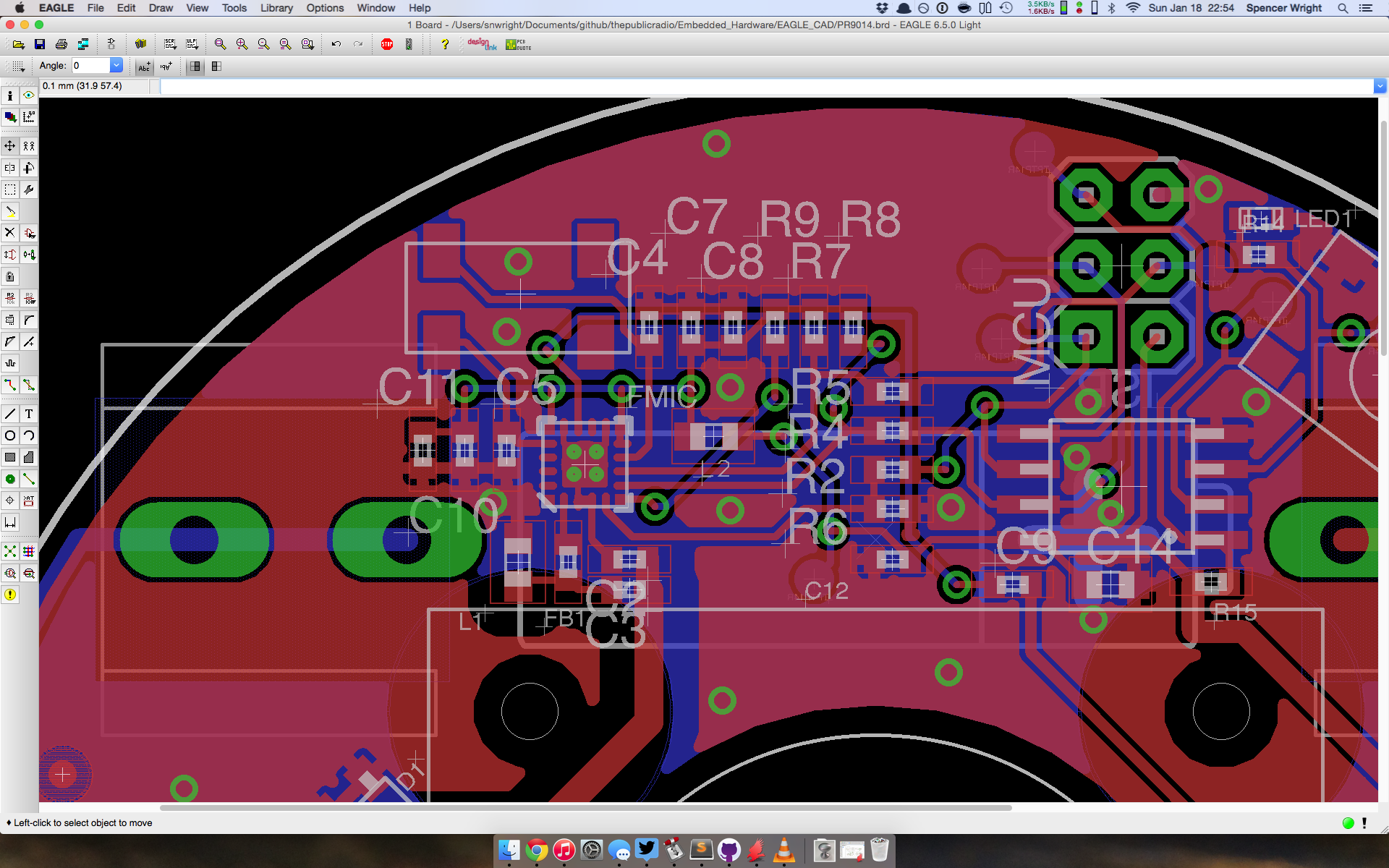

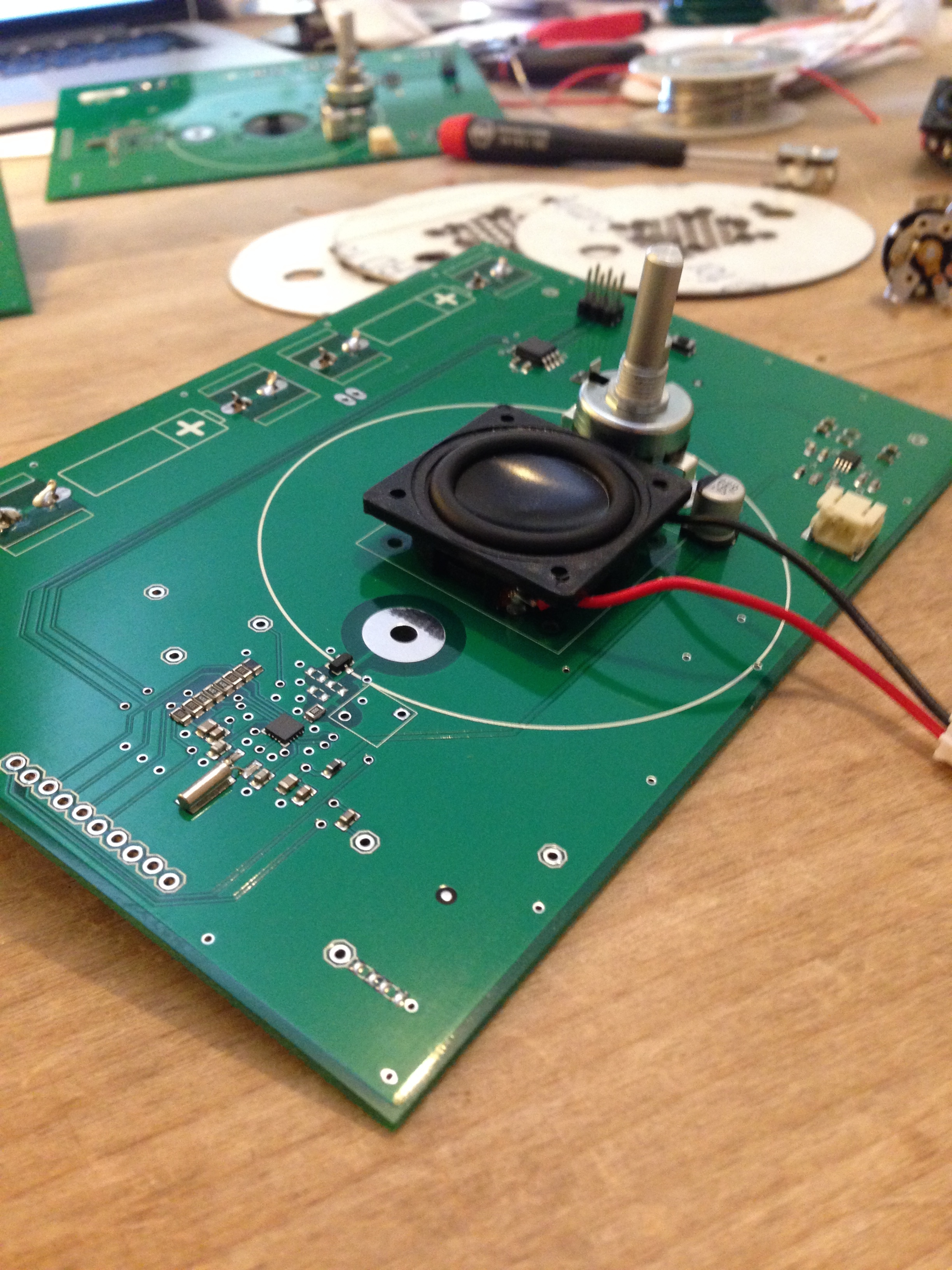

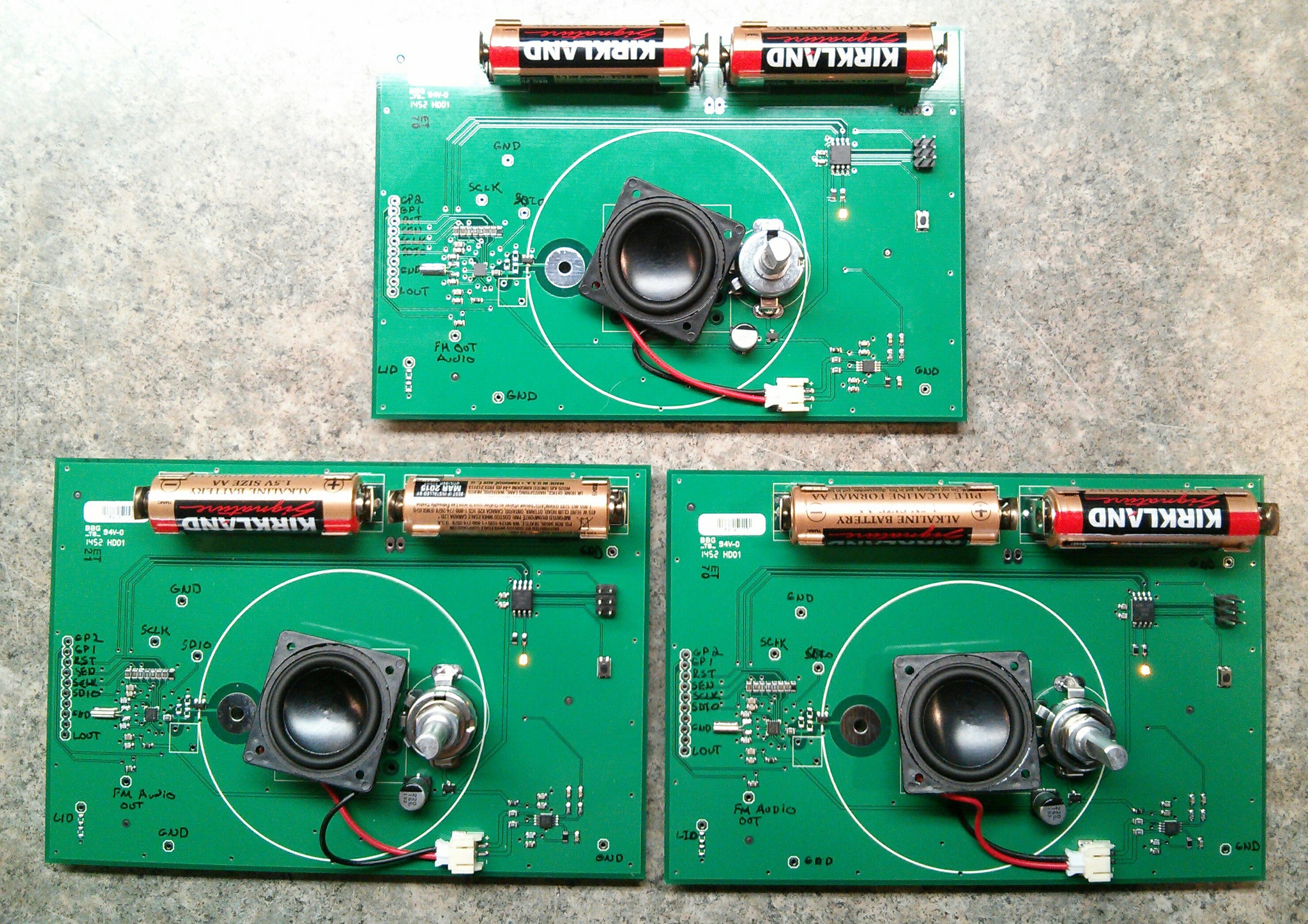

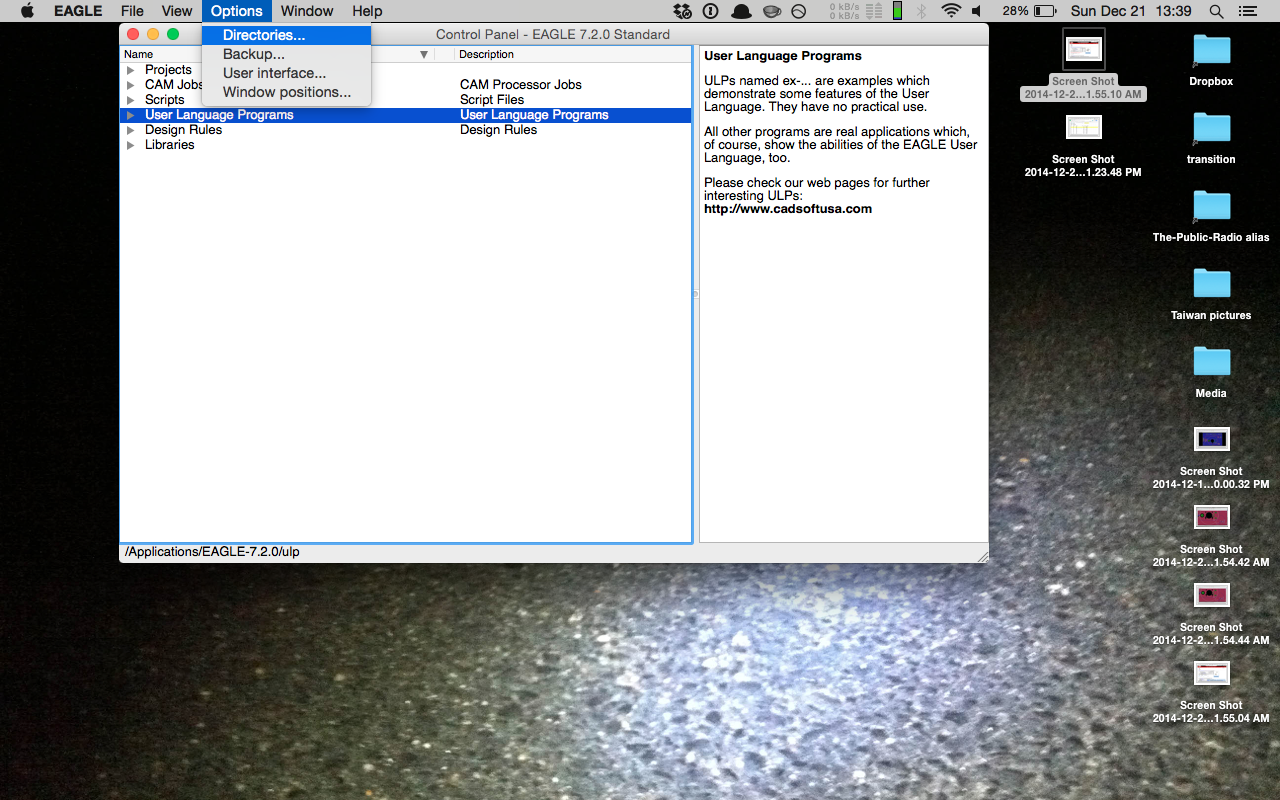

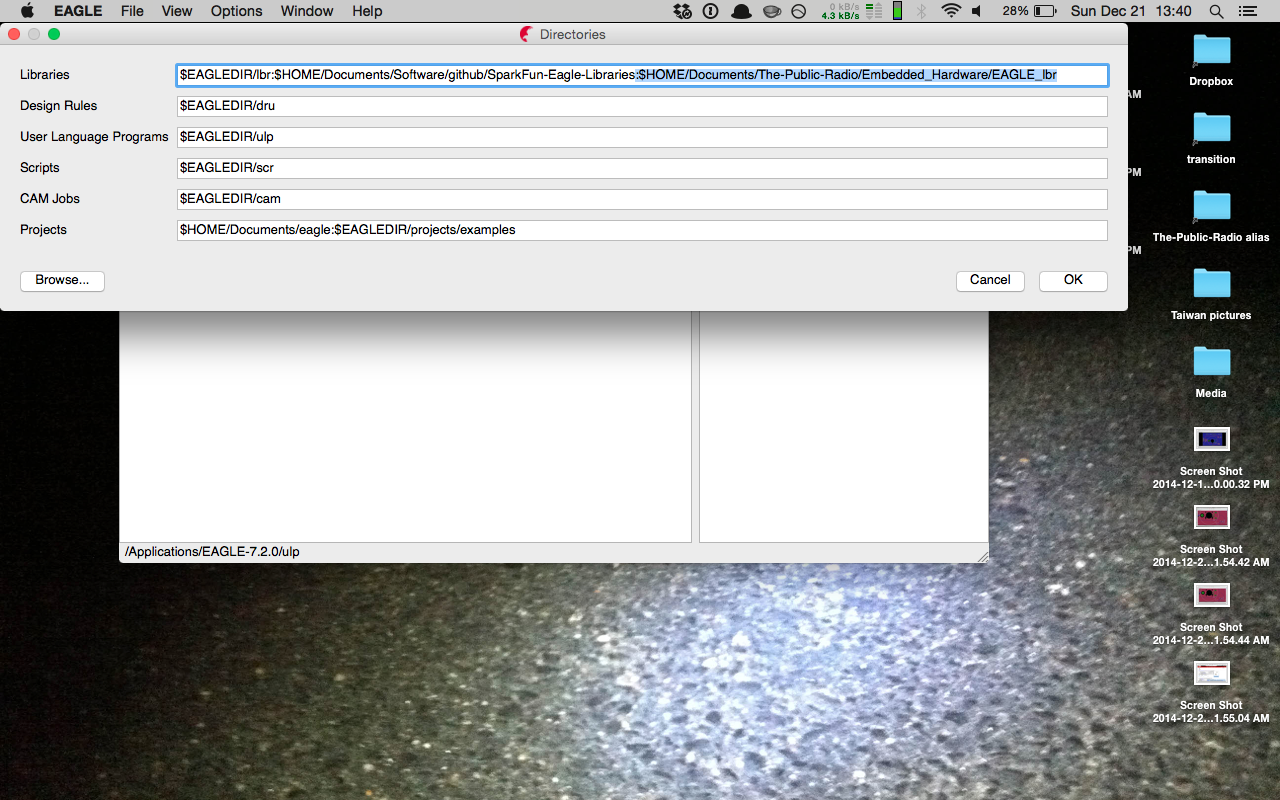

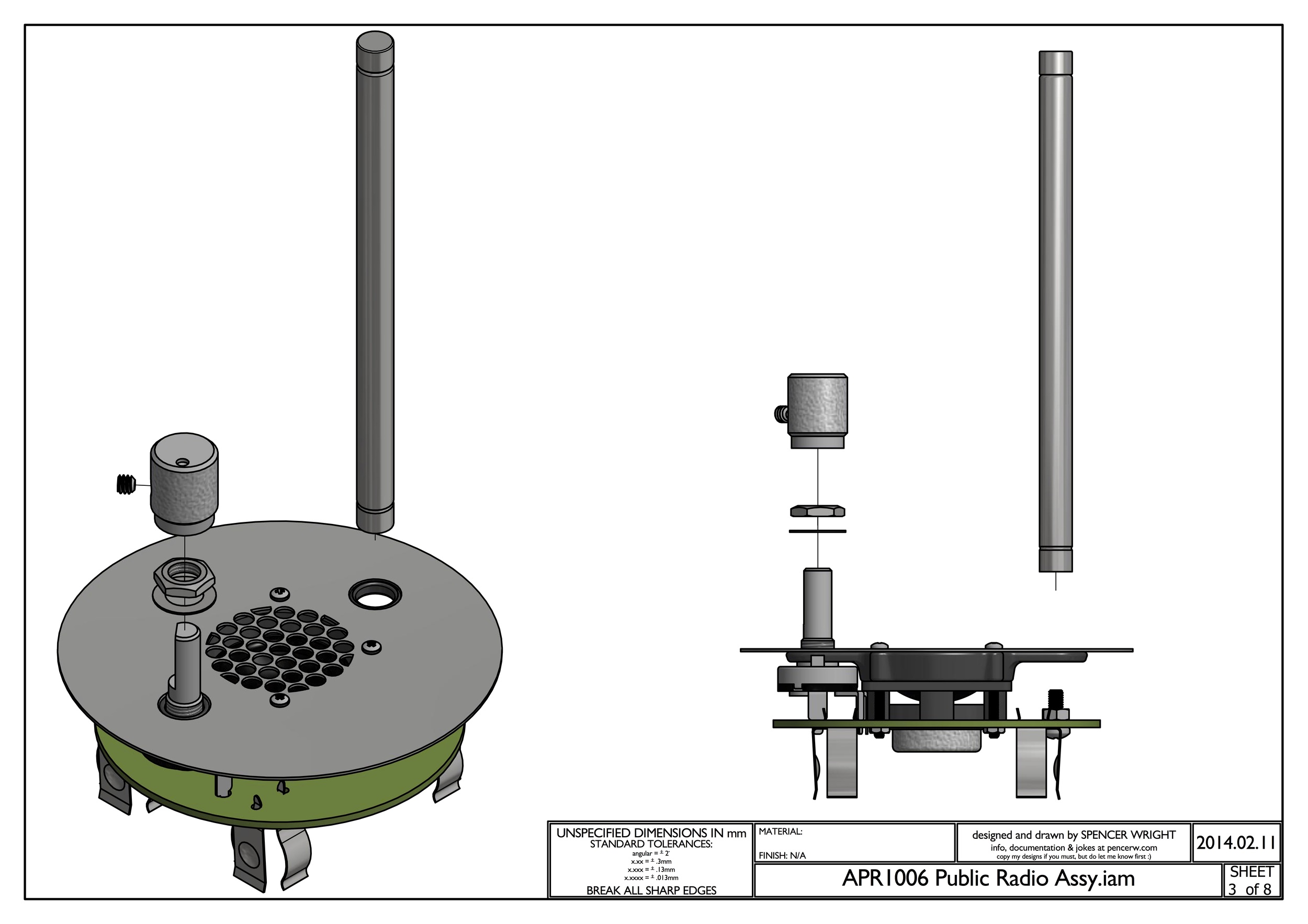

The entire time, we'd never looked critically at The Public Radio's amplifier - a TI TPA2005D1. We had chosen it mostly because it was available and easy to develop with (i.e. Sparkfun sells a development kit with it), but its efficiency was also a key selling point. The TPA2005 is a Class-D amplifier, which means that it amplifies the audio signal as a series of pulses. These pulses operate at a frequency of about 250kHz, and the whole device has a much lower duty cycle than Class-A, -B, or -AB amplifiers, all of which operate more or less continuously. Because Class-D amps have such low duty cycles, they're way more efficient than linear amps. We wanted the Public Radio to have as long a runtime as possible off of a single set of batteries, and so we stuck with the TPA2005D1 to minimize quiescent power consumption and increase life.

But that switching frequency... Once we pulled the amp off The Public Radio, the audio quality improved dramatically. The 250kHz stuff happening on the amp must have been creating harmonics into the mHz range, and that noise had been getting onto the rest of our board and making our lives *very* difficult. It's possible we could have gotten rid of it with some clever filtering, but the bottom line is that it didn't matter: the difference in power consumption is mostly when the input is low, which is never going to be the case when you're listening to HOT97. And anyway we're talking about dozens if not hundreds of hours of runtime regardless - and the difference isn't something that most listeners will ever notice.

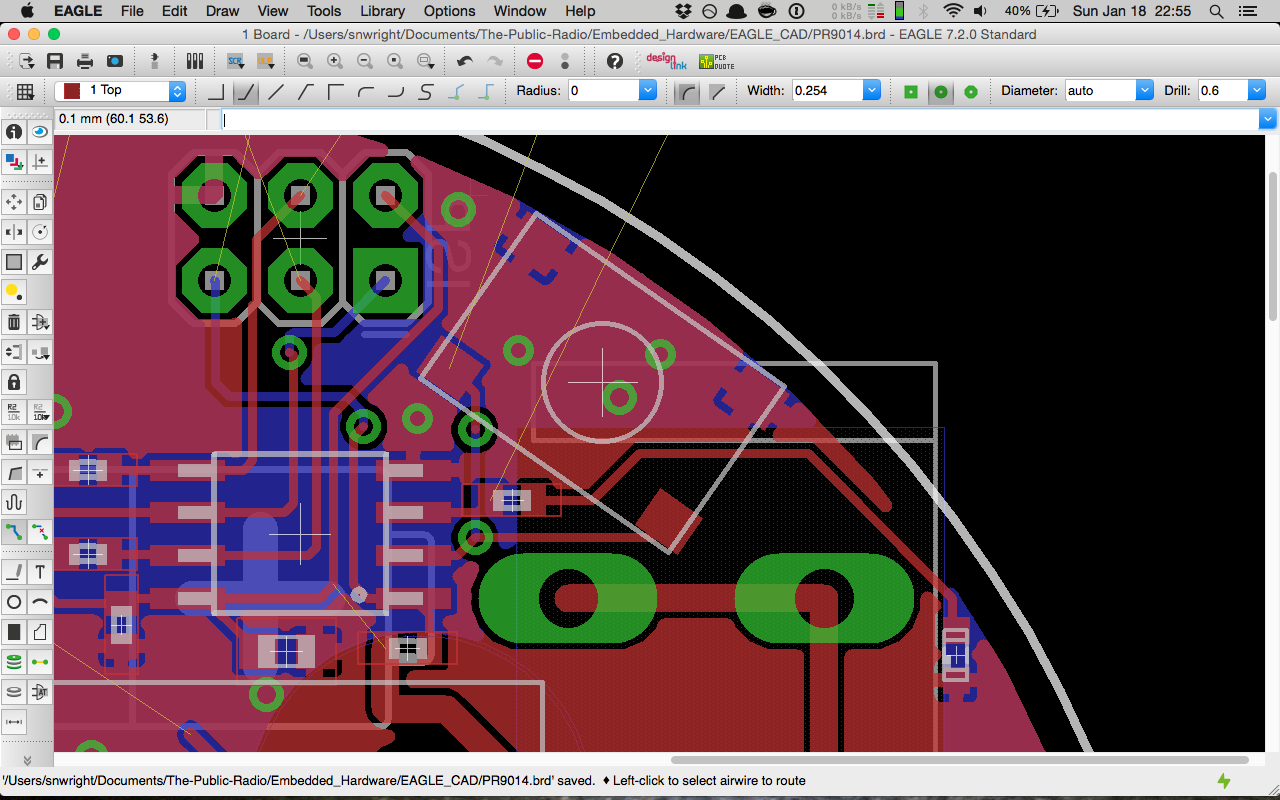

So: Class-D amp out. Class-AB amp in.