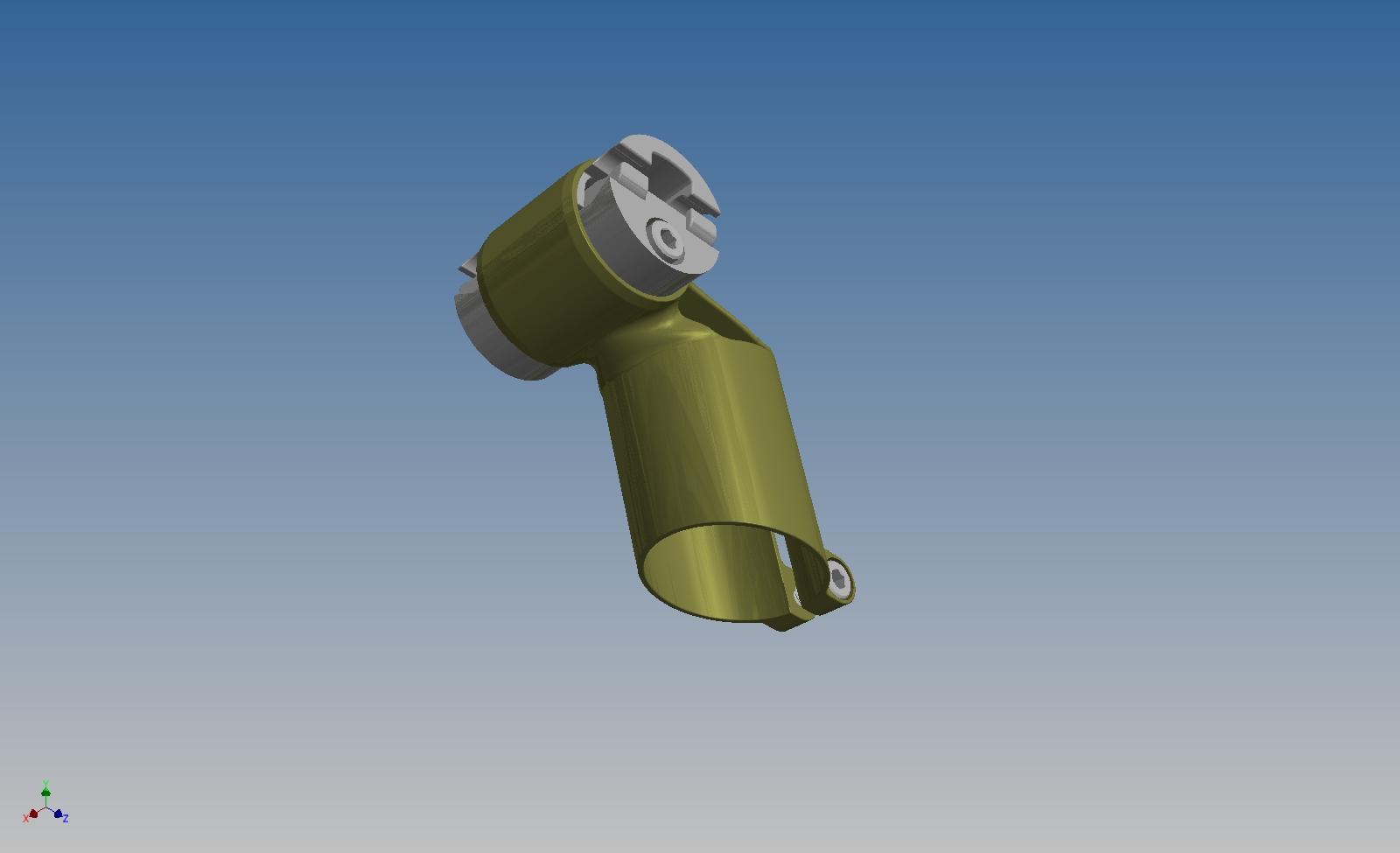

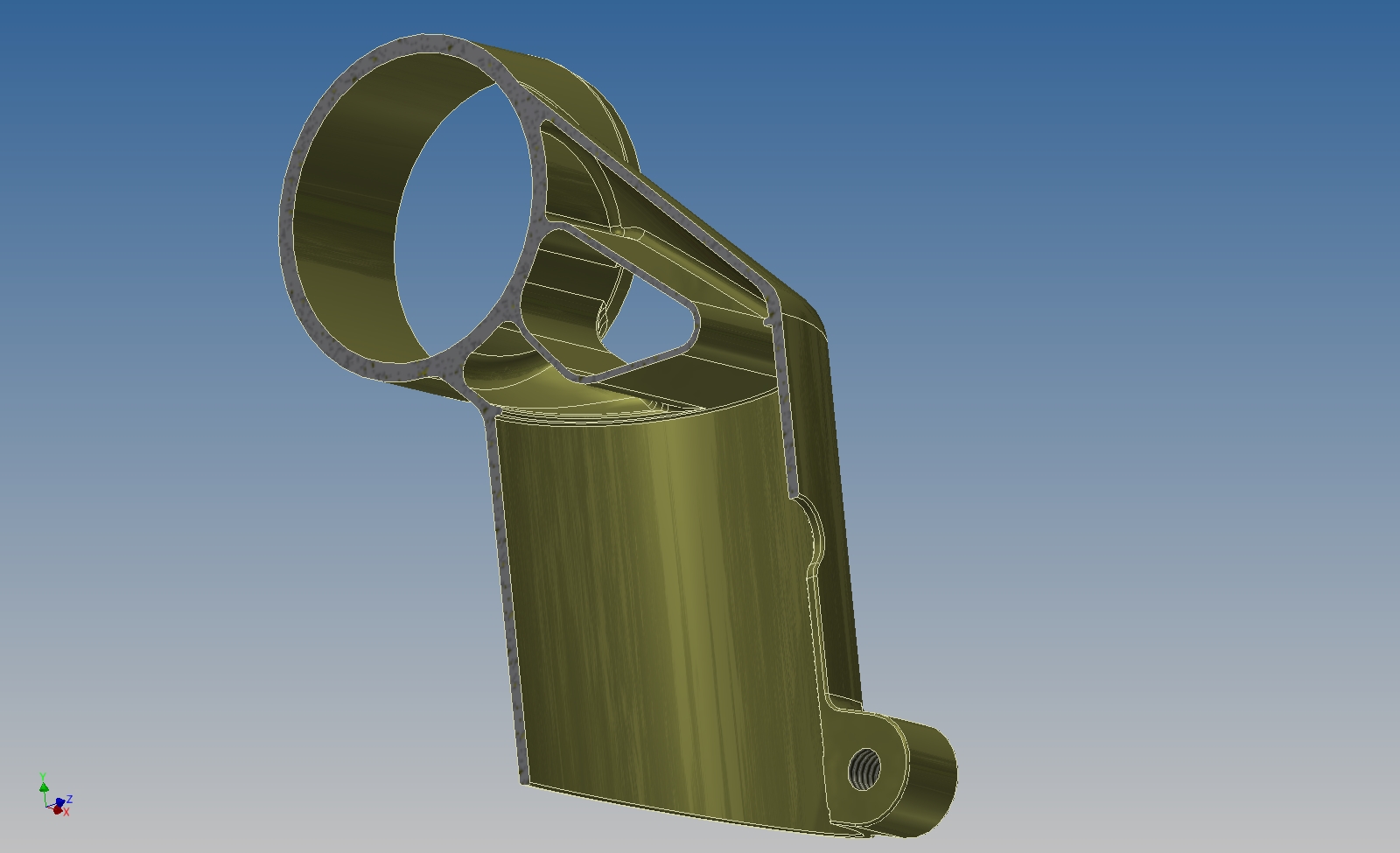

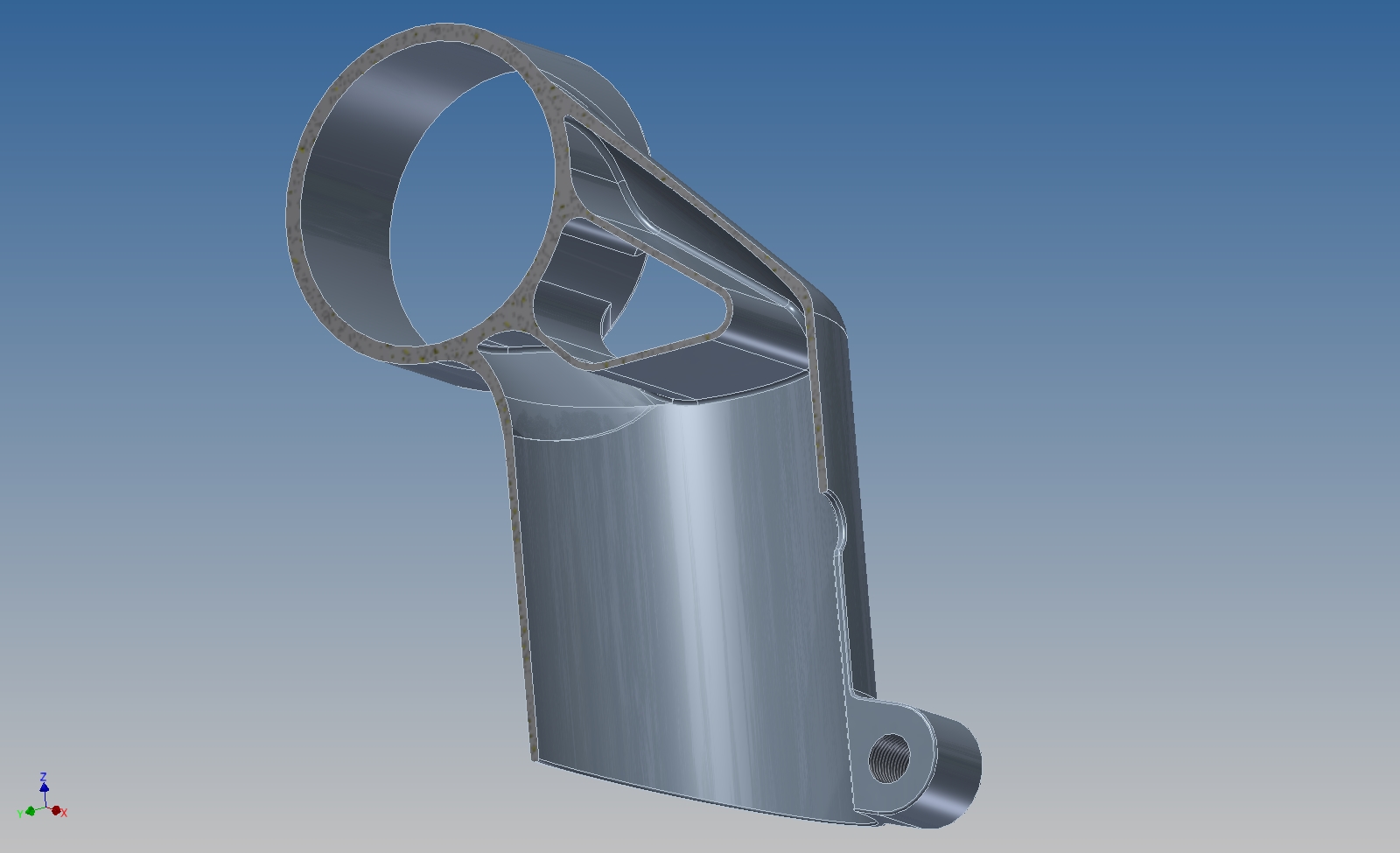

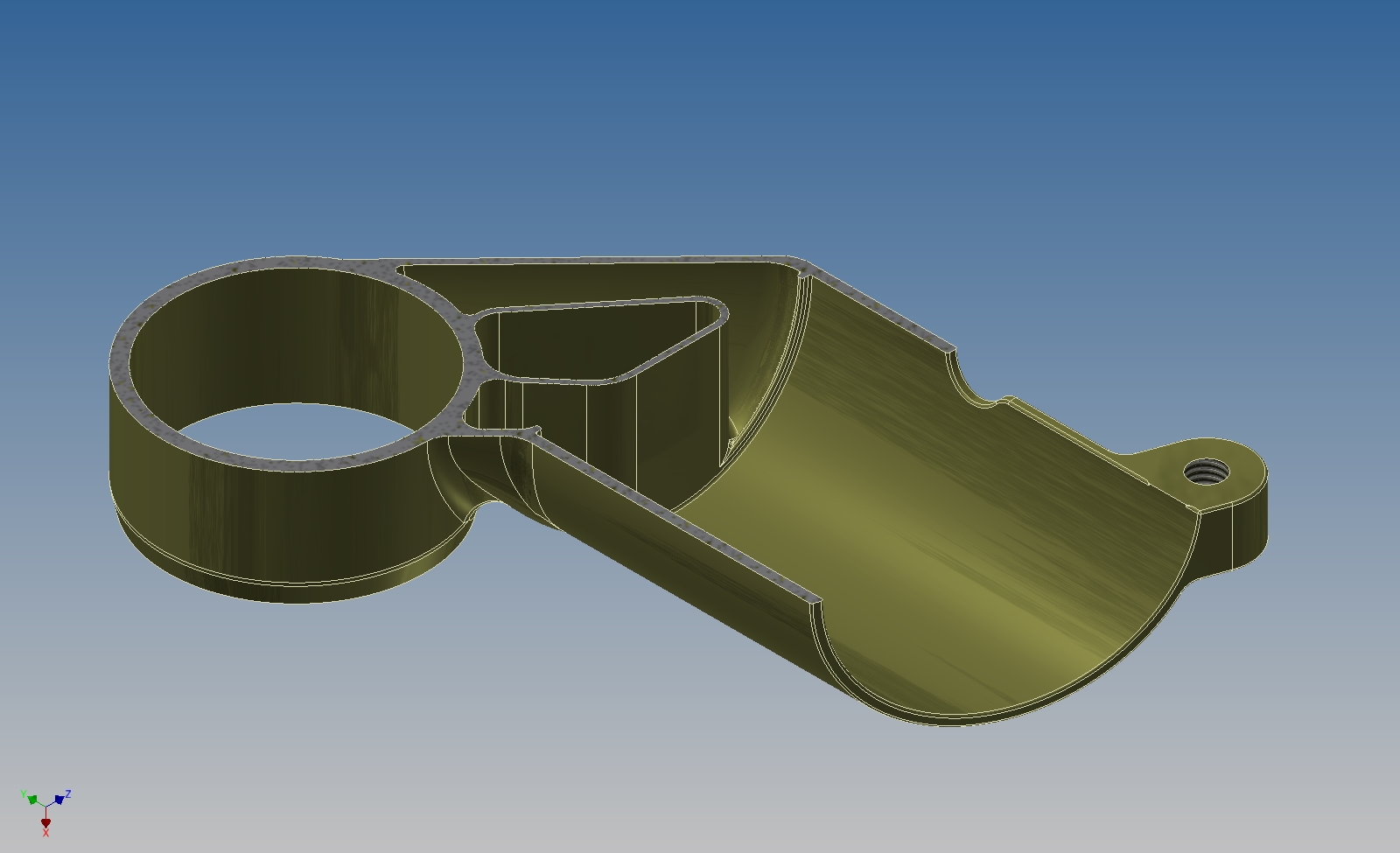

It's subtle if you haven't been looking at this the past few weeks, but this model has seen a bunch of improvement in the past two days. These interior surfaces, and the variable fillets connecting them, are pretty cool.

Update: The Public Radio

I'm not going to go into the details here - it'll be posted on the Public Radio Tumblr soon - but Zach and I have spent a bit of time reconfiguring our MVP in the past week. The result should be done next week (pending a new 3D printed lid prototype, etc) and will cover all of the functionality of the end product. Right now it's a protoboard, an Arduino Pro Mini, and a couple of (meh) Sparkfun boards.

The shitty thing is finding a potentiometer that will work well. It should be a 10K pot, logarithmic (audio) taper, with a switch. Unless I'm missing some hidden trove, there are about 7 parts in the world that fit those criteria and are stocked in quantities of more than a dozen. And then 5 of those have PC pins, when I think I'll end up needing solder lugs... it's a huge PITA.

Anyway, the project is moving along. More updates soon.

Also

Variable fillets are cool.

It's a little hard to tell, but I'm filleting an edge on the interior of the part here. Because of the particular geometry, I really want the fillet to be big in the middle and small on the sides, so I define multiple points on the edge and tell Inventor to blend fillet radii along the edge.

It's worth noting that all of this is some decidedly 21st century shit. Which I think is cool.

Less sketches, etc.

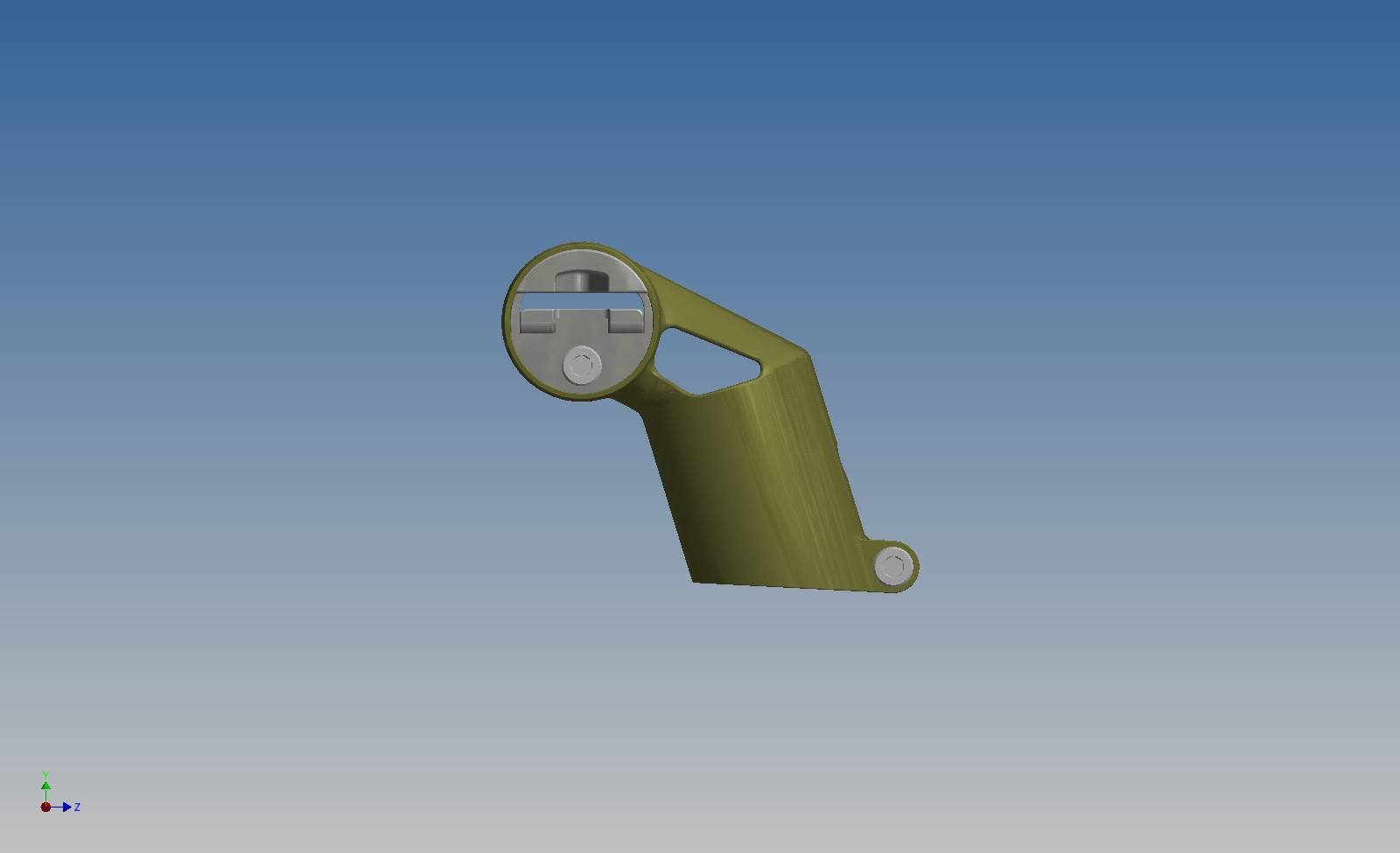

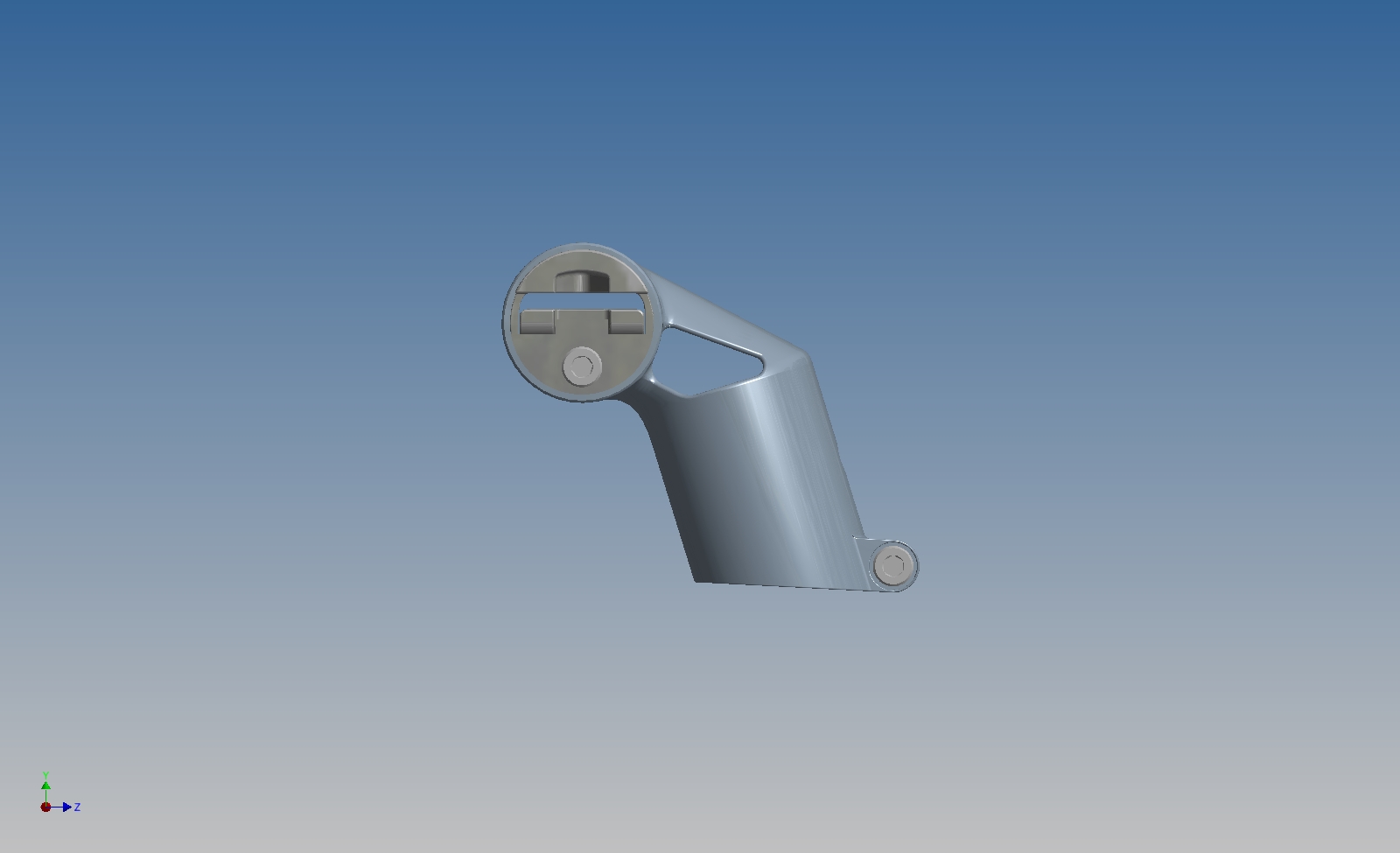

TOPPER PROGRESS UPDATE! Prettier, lighter, stronger.

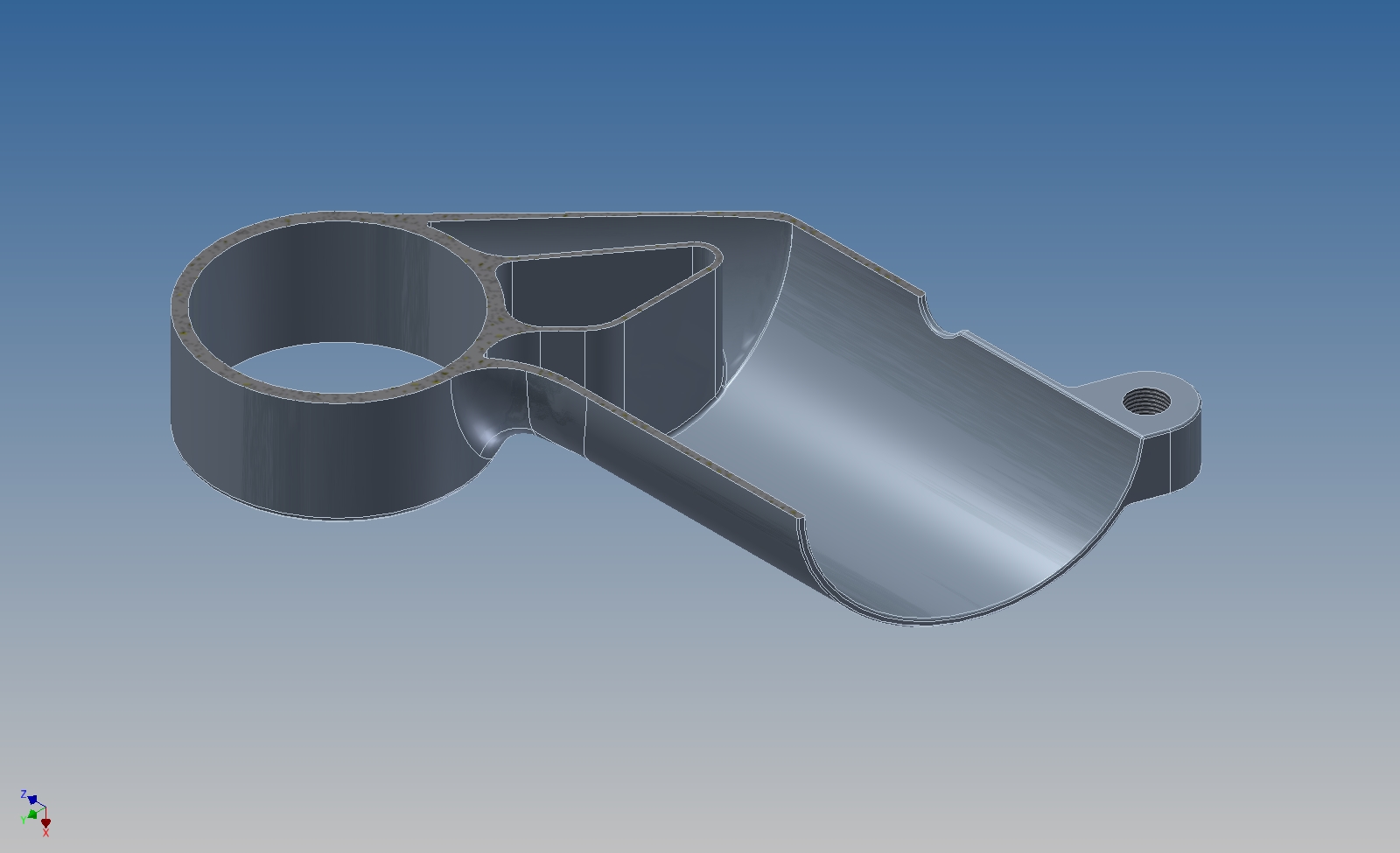

I ended up rebuilding this model completely today. This is 100% NURBS surfaces, and is about 80% of what I want it to be... which is just about right, considering where the product is at, lifecycle wise.

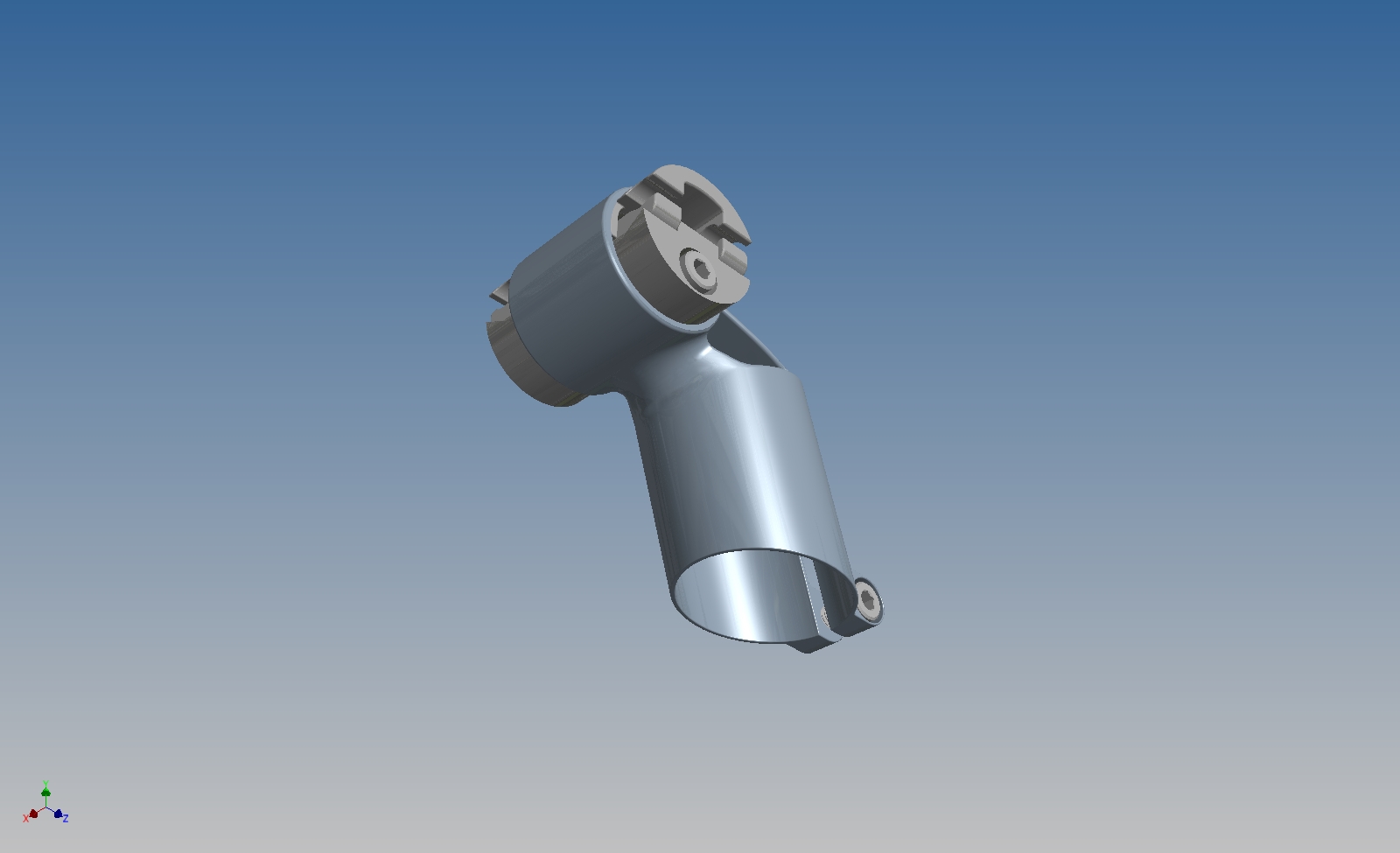

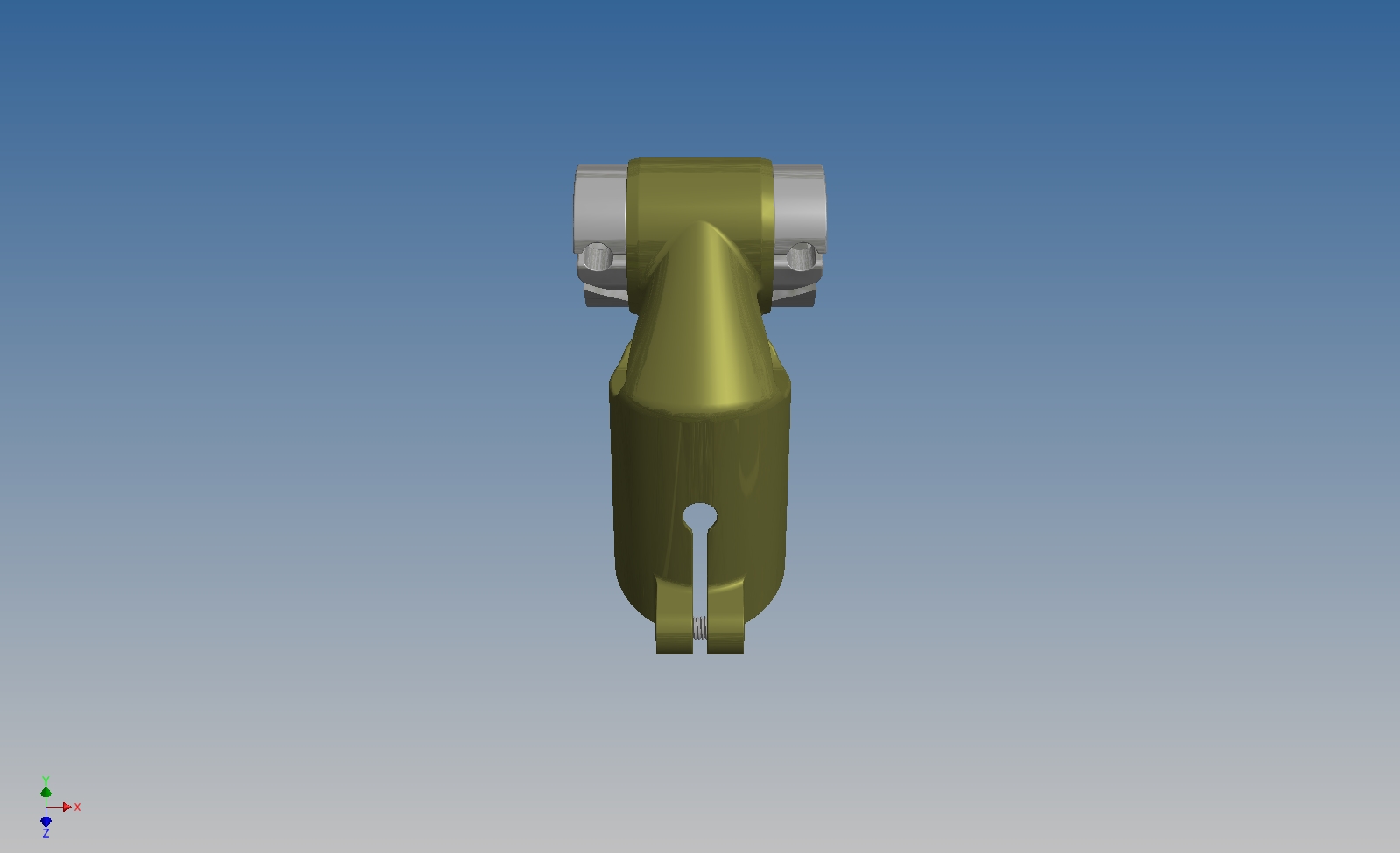

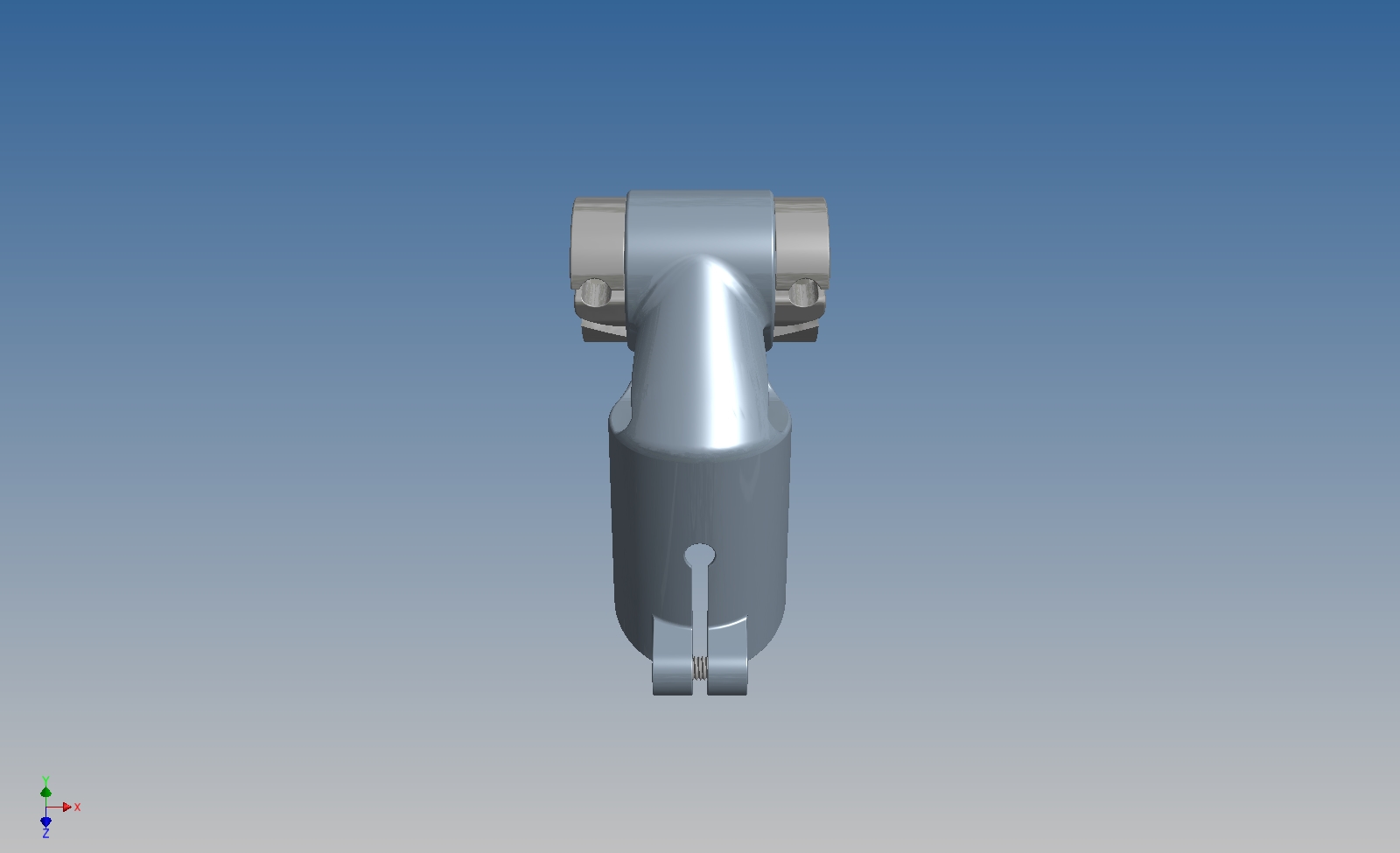

In all of the mini-galleries below, the new part is shown in blue-silver; the old model is gold.

The most noticeable change is in the bottom/rear of the lofted middle portion. I added a few rails to guide the outer surface, and worked to blend the loft more with the clamp body - and the barrel.

The front of the part looks pretty similar, but the bulge in the back is now gone, and a number of the transitional surfaces are more fully blended.

I also optimized the window shape a bit in order to reduce stress in the corners.

But the bigger changes are on the interior surfaces. There, I created fully tapered faces, which distribute material just where it's needed. The resulting structure is lighter and less prone to failure. It's a bit hard to see, but the new part has an arc-shaped inner wall on the top right, and the bottom left wall of the lofted transitional portion has a completely different - and much improved, I think - shape.

You'll also notice that I removed the little ledge around the perimeter of the inner diameter of the part. It was originally intended to be a hard stop for the seatmast to bottom out on, but I was able to eliminate it - while retaining the core function - but moving the window's bottom edge to the same plane.

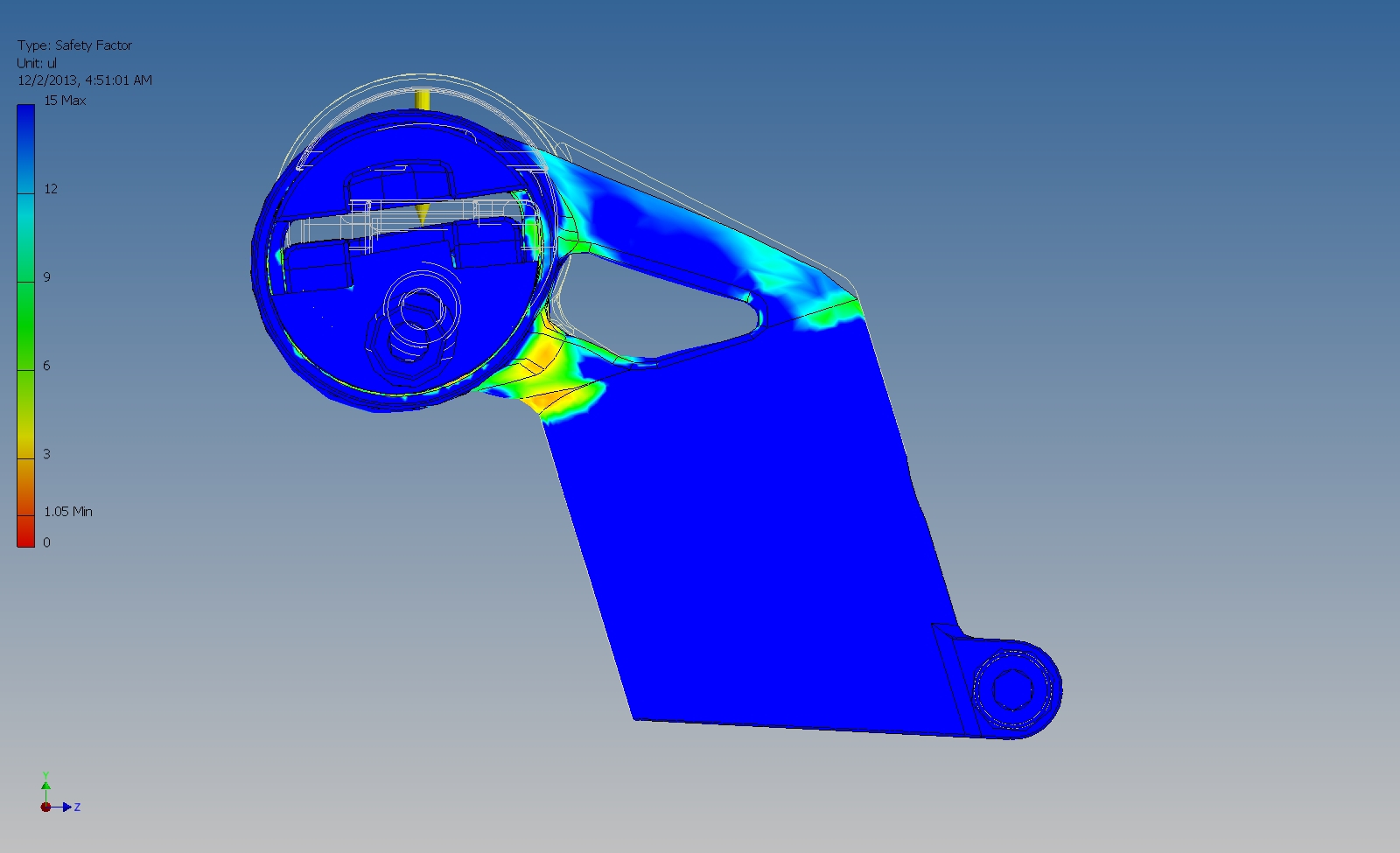

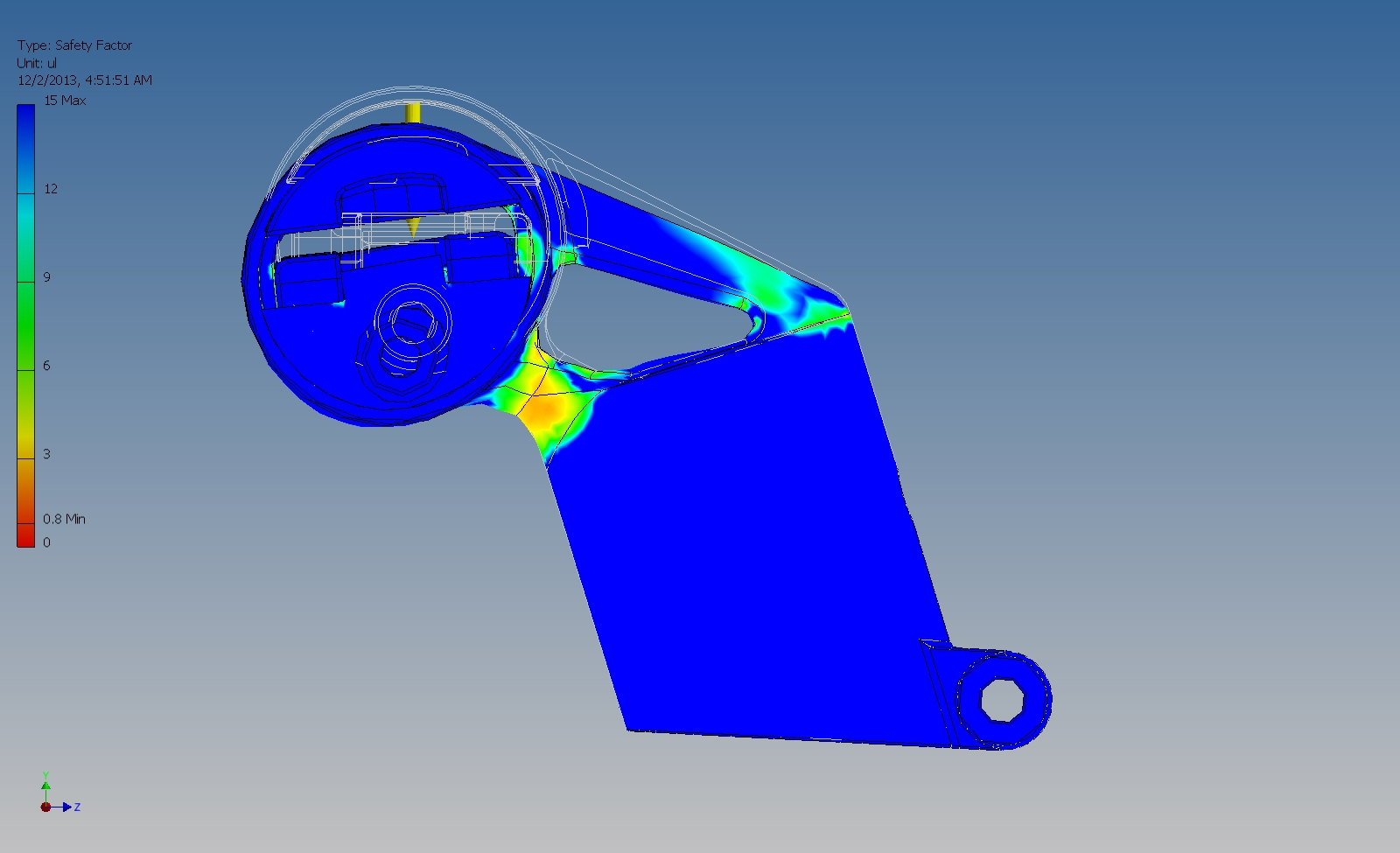

The result is much more organic, and distributes strain more evenly around the part. I'm not totally done fine-tuning it, but the initial FEA results are promising.

As you can see, the corners of the lower section are stronger now, and strain there is more evenly distributed. And because of the way I rebuilt the model, it shouldn't be too hard to beef up the necessary portions a bit.

Although I'd like to take another shot at some of the loft geometry, I've been thinking ahead a little too. I suspect that the clamp portion can be relieved a bit, and have been playing with some shapes... I rather like the result :)

Too Many Sketches

I've been working on optimizing the Topper a bit, which has involved starting from scratch and remodeling the loft a little smarter.

...But it's getting complicated. There's *way* too much here, and this is a stripped down version of what I had last night.

Basically, NURBS surfaces kinda suck - building this loft is a PITA. I would try this in Fusion 360 with T-splines... but I'm hesitant. Last week's version was pretty close to where I wanted it, and I thought that I could rebuild it quickly and move on. My work this morning will tell whether I was wrong.

Quick Pitch: Moves App for Time Tracking

I'm currently using Moves to track my physical activity. Moves uses motion & location data on my iPhone to see how far I walk, run, and bike during the day. It integrates with maps & the Foursquare API to add data about what locations I visit and my routes of travel.

I want the same thing, but for my desktop & mobile computer usage, with the end result being that I can track what projects and activities I'm working on. Let's call it Works. It's a tool for freelancers & employees to automate time tracking.

It's most important for me on my desktop computer. By tracking which processes are running and which windows are in the foreground, Works can tell me what work activities I'm engaging in. If I've got Inventor open, I'm 3D modeling; if it's Arduino, I'm programming. If my browser has Digikey and Mouser tabs open, I'm doing electronics research & procurement; if my Gmail tab is in the foreground, it's probably client relations. Etc.

Dig a layer deeper, and Works could start to analyze the displayed content of the applications I'm looking at. Using simple OCR, it could quickly determine part names of whatever I'm modeling; recipient names of the emails I'm composing; etc, and use that data to get an idea of what I'm doing and who I'm doing it for.

All of these datapoints are input into a time management spreadsheet with timestamps. Works could sample 'top' (the command line application) and a screenshot every couple of minutes, scan the relevant data fields, and return its guess as to what project & process I'm currently engaged in. At the end of the day, it could prompt me to confirm that it's on the right track - much like Moves allows me to edit location data from Foursquare.

Right?

Credit to Zach Dunham for most of this idea.

Charity

Felix Salmon, from an excellent post arguing that privately-financed public parks (as Central Park mostly is) are a bad idea; emphasis mine.

Indeed, more generally, the big problem with the charitable-donation tax deduction is that it’s effectively a multi-billion-dollar tax expenditure on the rich, even as charitable donations by the majority of the US population don’t get subsidized at all. If it were abolished, or scaled back, the amount saved by the government would dwarf any reduction in charitable donations: in theory, the government could simply make up the entire shortfall and then some, and still come out ahead. As a rule, it’s always easier and cheaper for a government to subsidize something directly than it is to try to fiddle around with laws which have the same effect but don’t show up on the official accounts.

Sebastian Thrun on Education

From Fast Company's interview with Udacity CEO Sebastian Thrun; emphasis mine:

Thrun's 5-year-old son, Jasper, is not yet old enough to be impressed by his father's work, but he's already starting his education. "In my son's kindergarten, they're telling us how to get him into Stanford," he says. "By their advice, I'm doing everything wrong, because I'm trying to make him happy rather than putting him through as many piano lessons as possible." He dreams that his son will take a less conventional view of education. "I hope he can hit the workforce relatively early and engage in lifelong education," Thrun says. "I wish to do away with the idea of spending one big chunk of time learning."

Stress

This is modified a bit from last night. Fillets, window dimensions, and a few wall thicknesses are revised. Overall effect is that it's lighter and stronger.

Still more work to go, but it's getting there :)

Oh - and this simulation is 2000 Newtons - about 450 pounds-force.

Topper taking shape

Made a bunch of changes to the seatmast topper last night.

I ended up rebuilding the entire lofted body, which is basically the whole middle section of the part. Doing so allowed me to modify it down the line, which is really useful when building NURBS surfaces. After making the outside shape, I ended up needing to tweak it a lot to avoid collisions with later features. Accommodating these changes is hard to do, though - you kind of need to know what the part is going to look like before you start. It's a real chicken-and-egg problem. What usually ends up happening is that you don't do it right until you've rebuilt the whole model three or four times, which is about where I'm at here :)

It's hard to describe, but the upper section is hollow. I also spent a while trying to optimize around shared surfaces, so the window upper & lower walls coincide with features that I already needed on the part. The one thing I'm not particularly happy about is the seatmast clamp at the bottom of the part. The details are a little different, but overall it's designed the same way it would be if the part was welded. This part is going to be 3D printed, though, and I'd prefer to find a way to build the feature in a way that directly addresses its manufacturing method.

But overall, the part is definitely forward looking. I'll post a section view later, but for now just take my word that most of the middle of the part would be impossible to make by any other method than additive manufacturing. Also, right now the topper body (just the gold part, not including hardware) comes in at 74g, and I suspect that with a little work I can shave that even more :)

Dog.

An old photo.

Next

True.

Couldn't have said it better myself.

Then there is something

via FFFound!

Aaaaand more T-splines.

:)

The Illinois

Frank Lloyd Wright in 1956 with his design for The Illinois, a skyscraper that would have been by far the tallest in the world. via A Conversation on Cool.

More T-Splines

This is pretty fun. The first shot is of the control frame view; the second is smoothed - which is how the part would be produced.

I'm new at T-spline modeling, and have a few issues with this model. Nonetheless, it's basically ready to be converted into a mechanical assembly. There, it would be split into a frame and arms; hinges would be installed; lens features would be designed.

Pretty fun.

Mailing List is Live.

And the signup is HERE.

A few questions:

Why am I starting a mailing list?

Because it's good.

Do people *do* mailing lists?

I don't know. Do people do RSS? Do they look at websites on a regular basis? If everything is going mobile (as it appears it is) then I'm guessing the answer to the above is "mostly no." I'm not sure email is the cure (cf. Paul Graham's "Frighteningly Ambitious Startup Ideas," point 2), but I'm trying not to try to change user behavior. And anyway, why *not* do a mailing list?

What's on this mailing list?

Oh, I don't know. Whatever. Something about behavioral psychology, something about probability. Something about design, or startup ideas. Maybe something from the Shouts & Murmurs section, or a link to an xkcd comic, or whatever.

Good stuff.

Are you gonna spam me?

Oh, give me a break. It's on MailChimp, it's standard operating procedure, etc. Plus I'm a decent person.

What else?

Is there anything else? I think that's it. Sign up, it'll be kinda fun.

Also @ Todd's

Progress: The Public Radio

Last night, Zach and I bribed Todd to help us jumpstart The Public Radio a bit. When we last worked on it, we had a short on the 3.3v line that we couldn't find. Well, that was fixed in short order, and we also were able to diagnose & fix a few other issues that we weren't aware of.

We left with a board that's still not quite ready, but it's getting a lot closer. We also had a few more thoughts about how we should be proceeding, and it seems likely that they'll brew into something more actionable in the coming weeks.

It seems likely that with another day's work, we could get this board tuned up and blasting HOT97 like it should be. At that point, though, we need to undertake a total redesign of the whole assembly. The PCB is the wrong size & shape; the speaker is too large; the potentiometer isn't long enough; the lid is the wrong thickness (and, ultimately, the wrong material).

It's also seeming likely that we end up redesigning the radio to be a simpler (and possibly analog) device... but that will only happen further down the line.