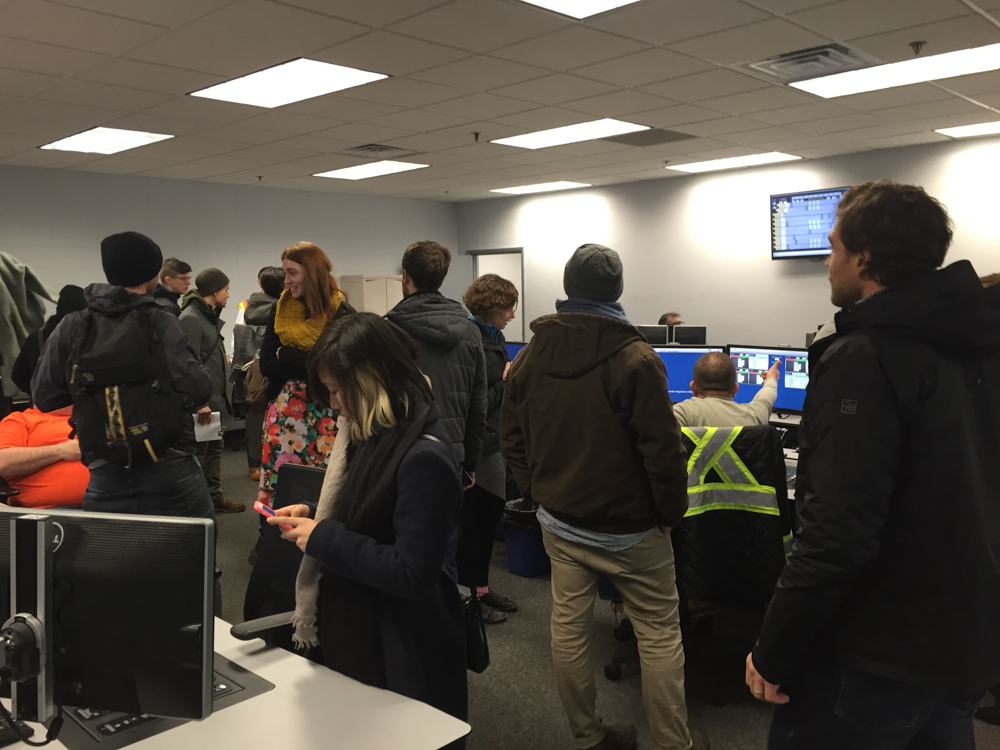

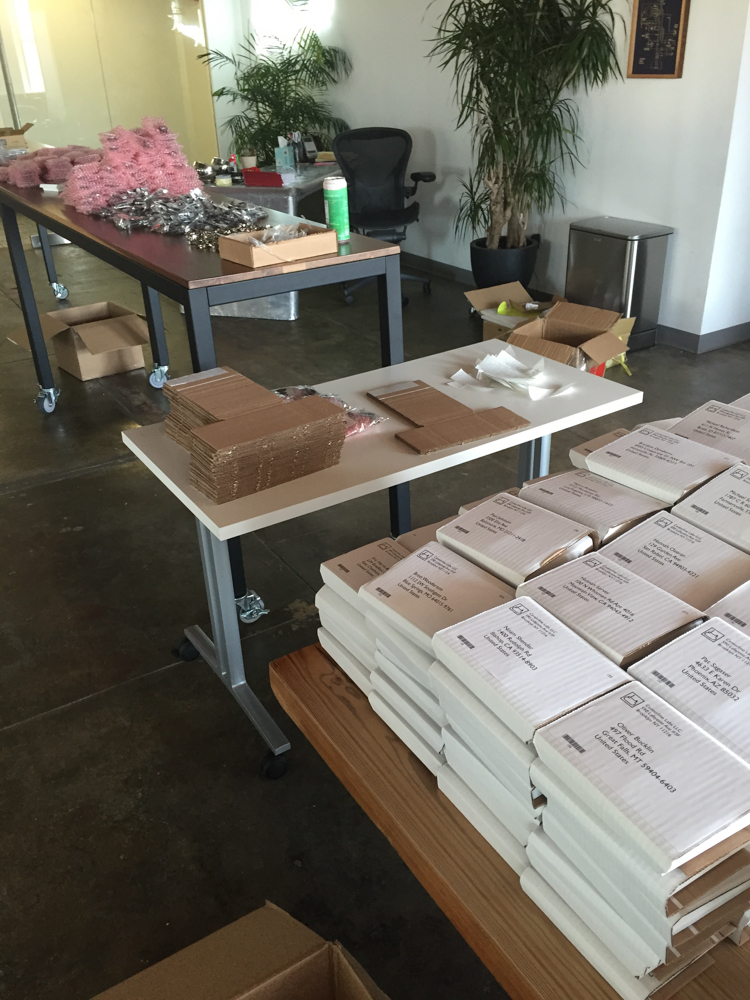

Yesterday Zach and I (with the *so* gracious help of Nick, Wing, Dara, Daniel, and Tracy) packed up about 300 of The Public Radio's Maker Kits and got them ready to ship to our Kickstarter backers.

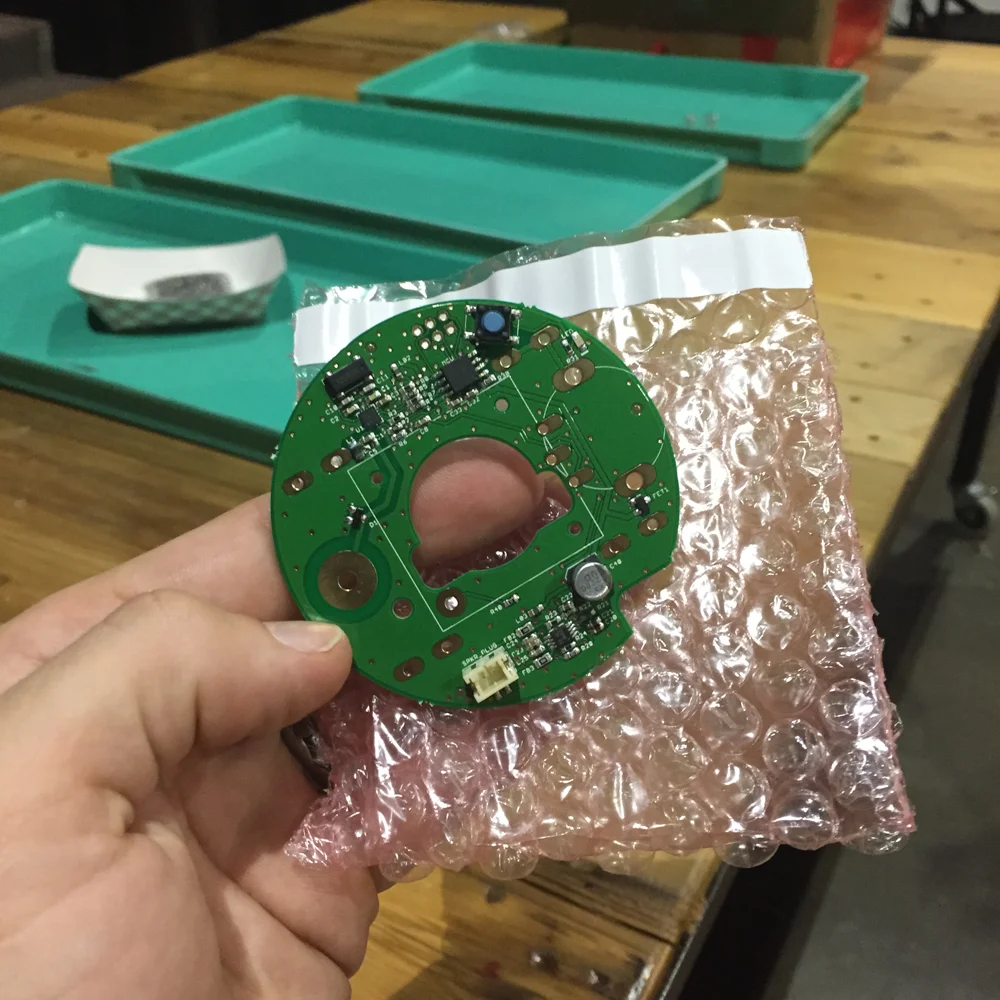

As the day progressed, the magnitude of effort it's taken to get here became more and more evident to me. We're about 5 weeks late shipping these kits, mostly as a result of last minute hangups in the production of our custom lids and speakers. While the lateness itself doesn't bother me *too* much, this milestone has been a big focus for both of us, and last night it struck me that I'm not sure I ever expected to reach it.

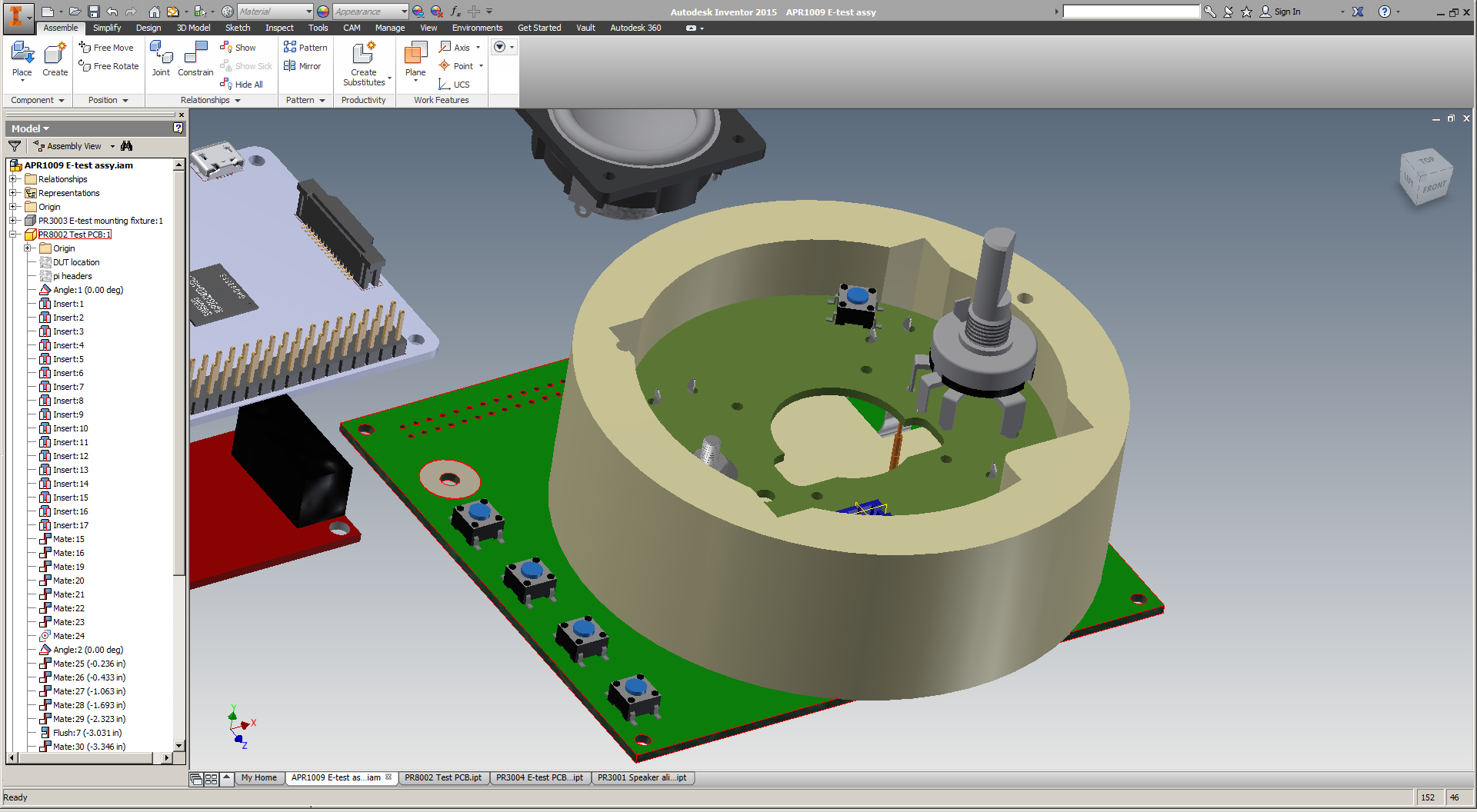

While I was packaging kits and wrangling our backer report into a format where our postage software could process it (at least for our purposes, Kickstarter's data management system leaves much to be desired), Daniel and Zach spent most of the day setting up our tuning script for the fully assembled radios. We'll start receiving those in about a week and a half, and the logistics around making sure they're tuned and shipped to the right backer is a pretty hefty task. We'll spend most of next weekend working on that, and in the meantime will continue to bug all the backers that never sent us their shipping info (if you're out there, HOLLER AT ME).

There is still a *ton* of work to do, but there will be a few more milestones like this in the next few weeks - and I'm *really* looking forward to them :)