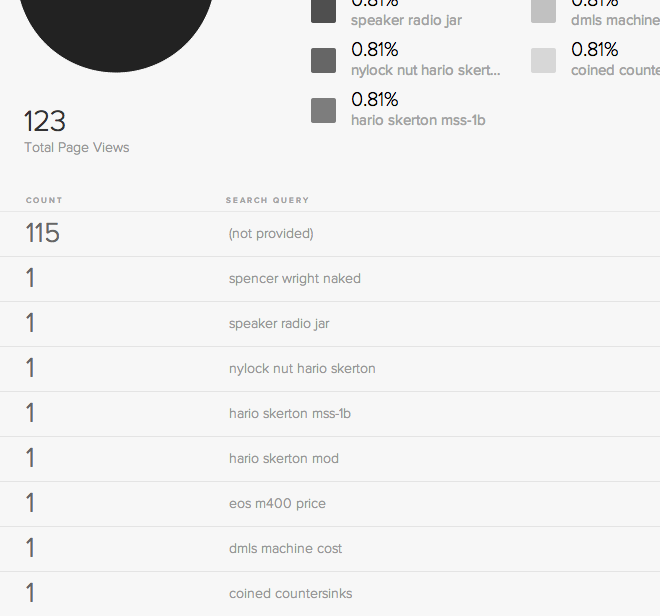

I can't tell whether to be flattered by this or what.

FWIW I am proud of most of these, especially "coined countersinks," for which I am *bafflingly* the top result. I also have reason to believe that a good number of the unprovided search results are for DMLS pricing, which is more exciting to me than the fact that someone wants to see me (or some lesser Spencer Wright) in the nude.