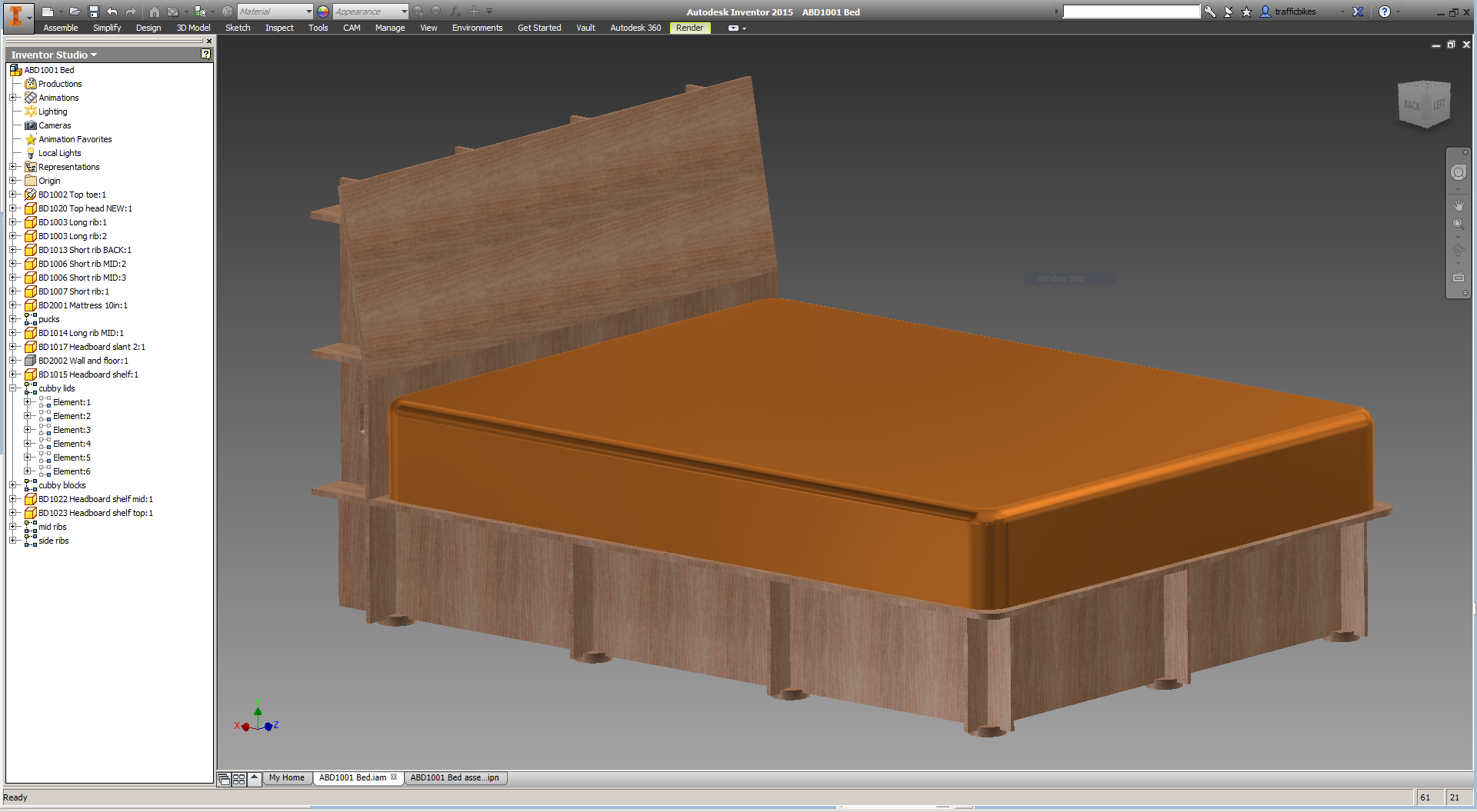

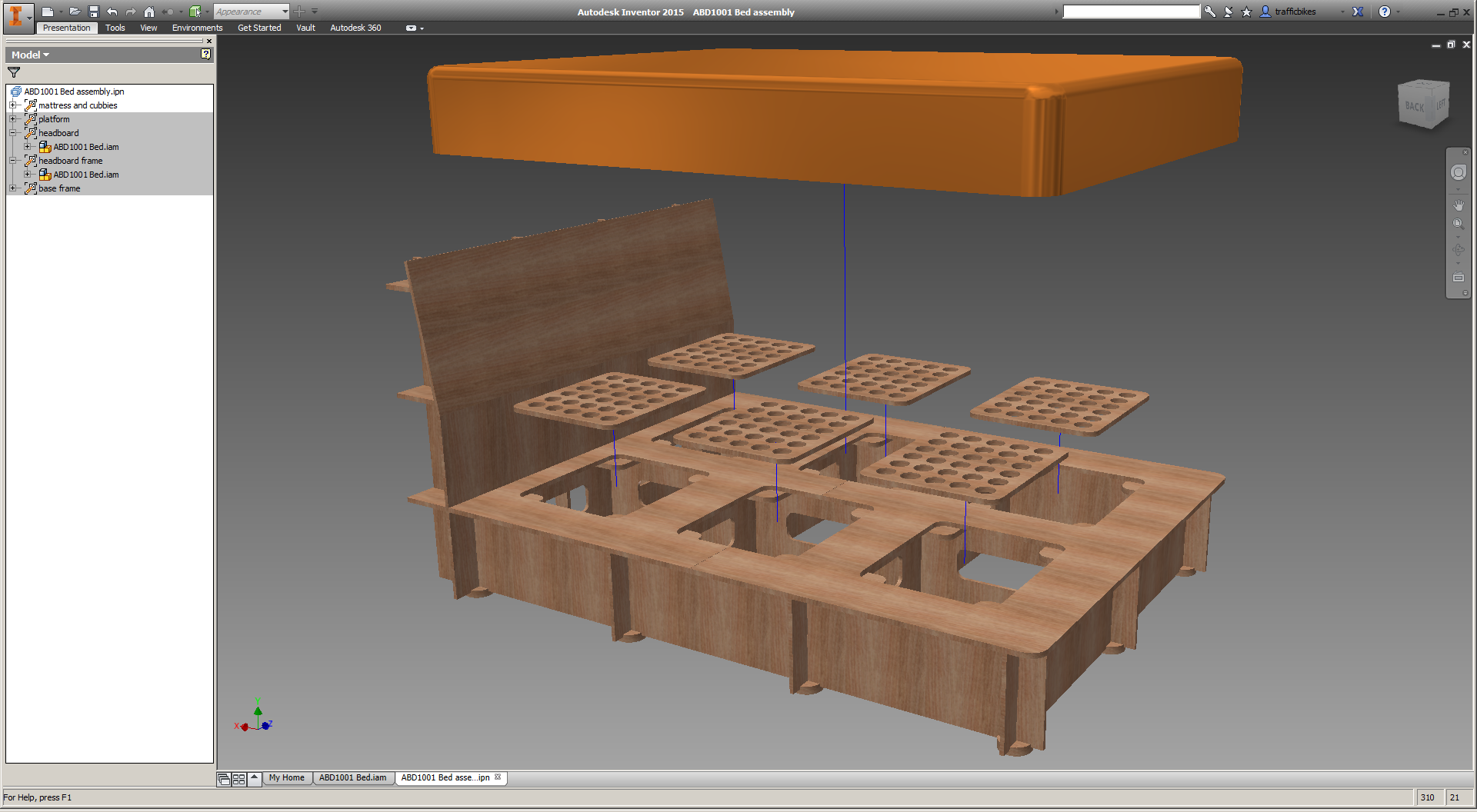

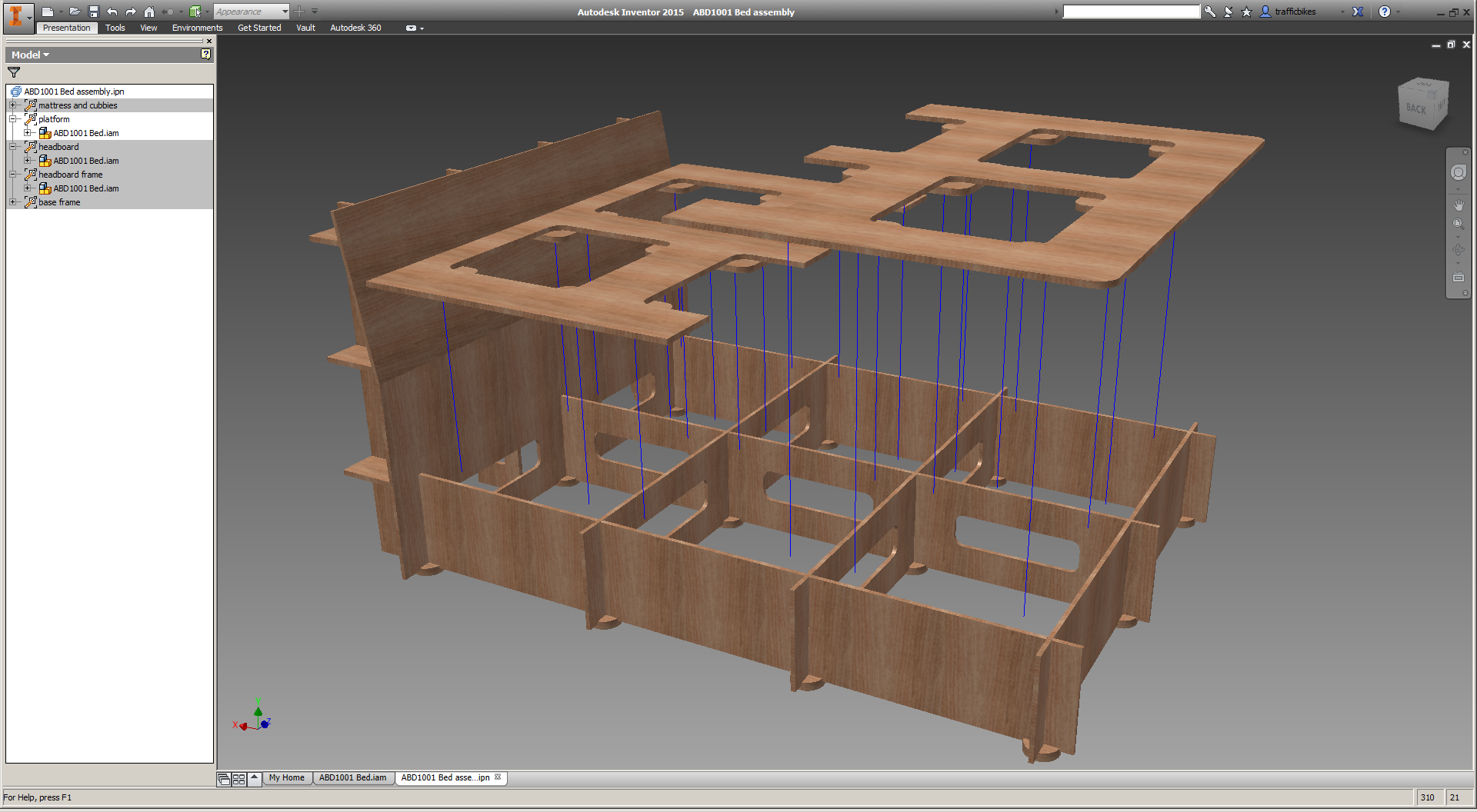

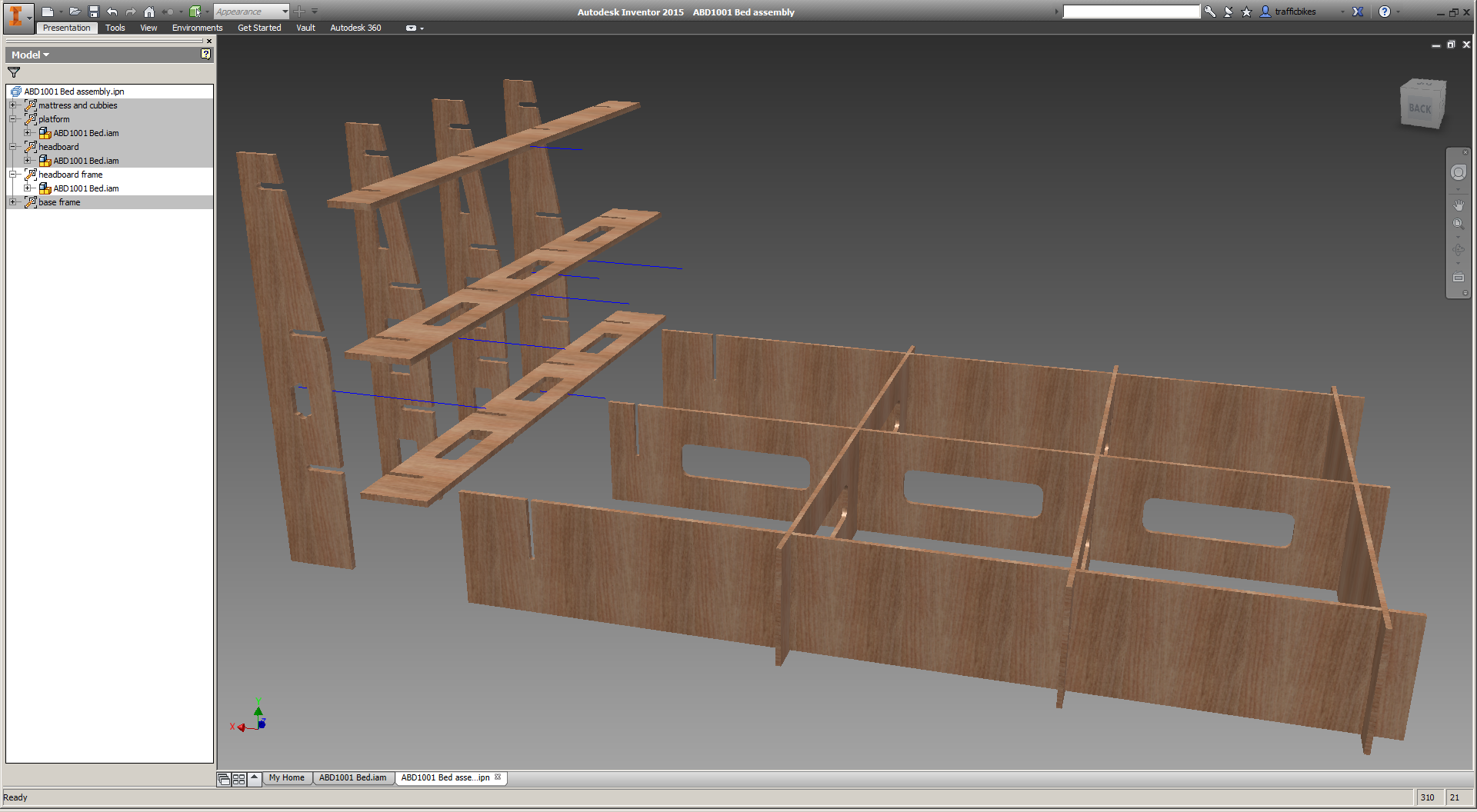

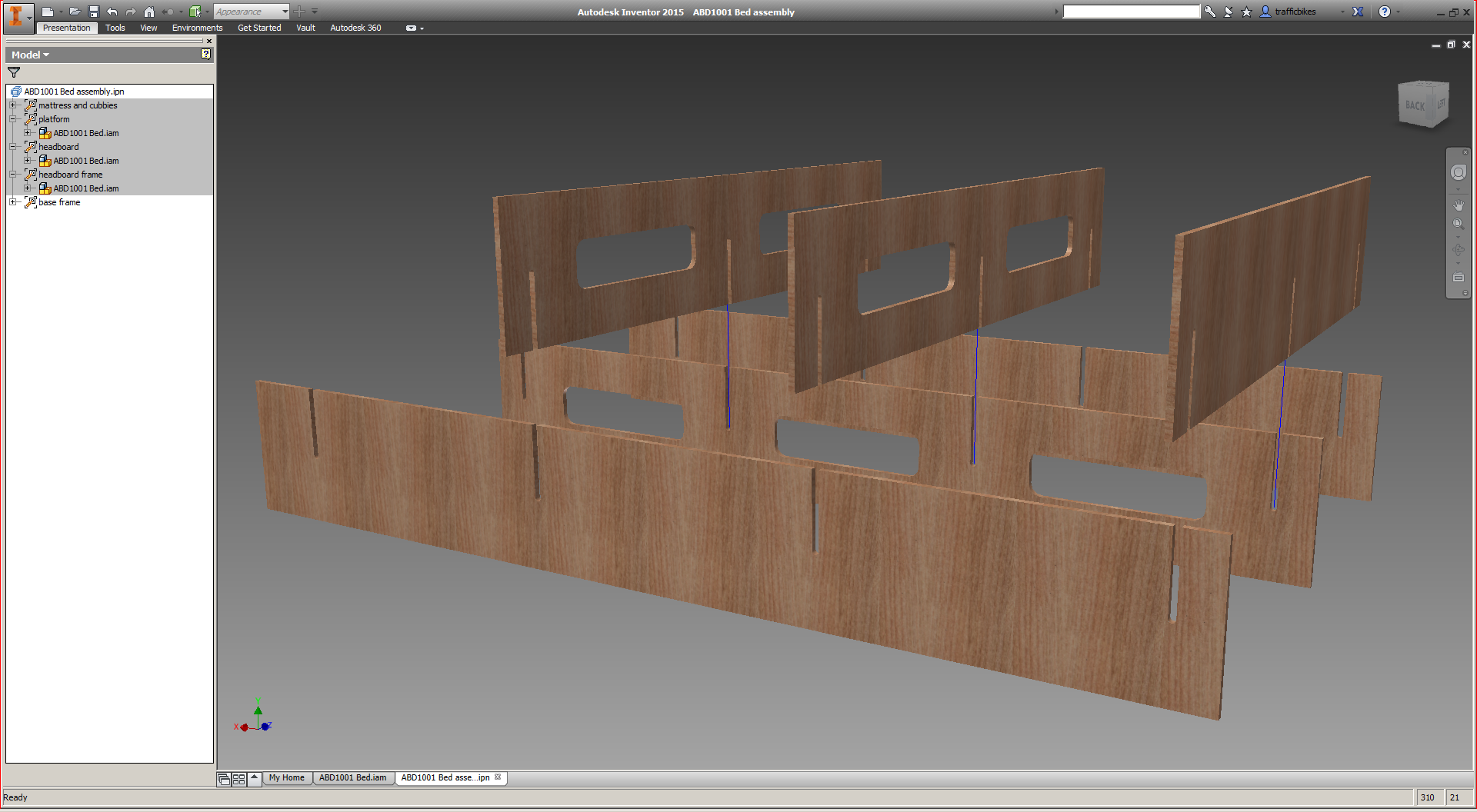

I spent basically all weekend putting my bed together.

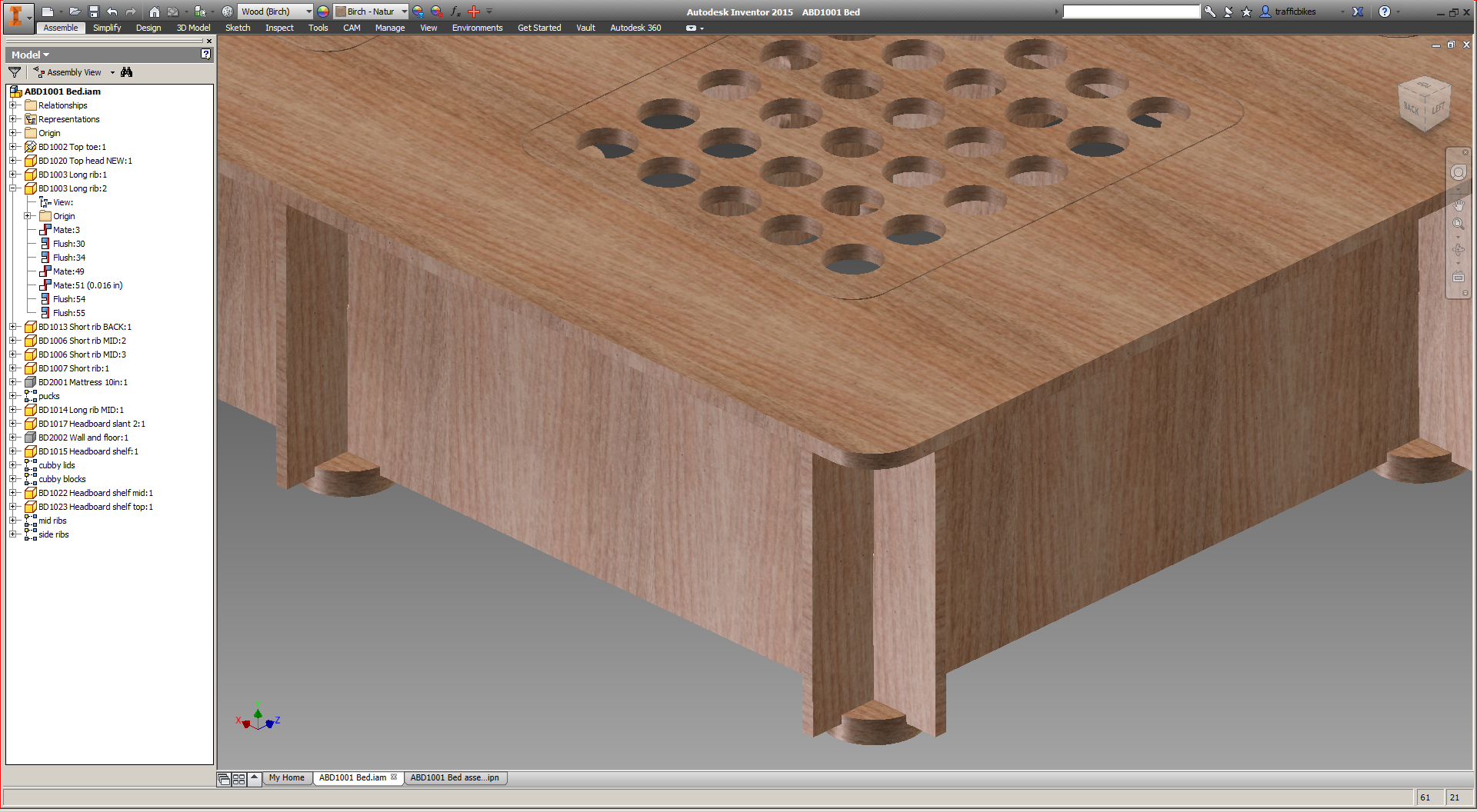

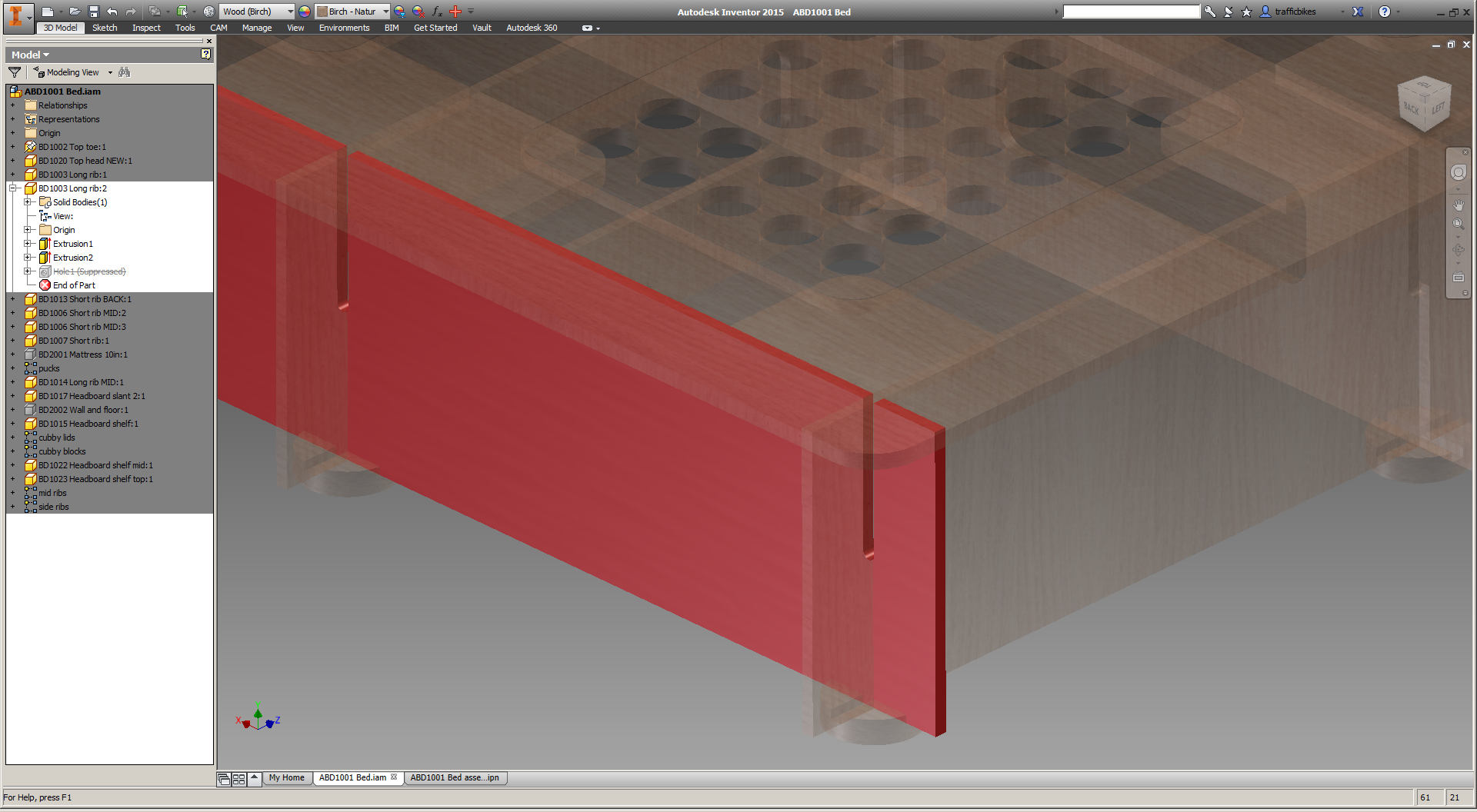

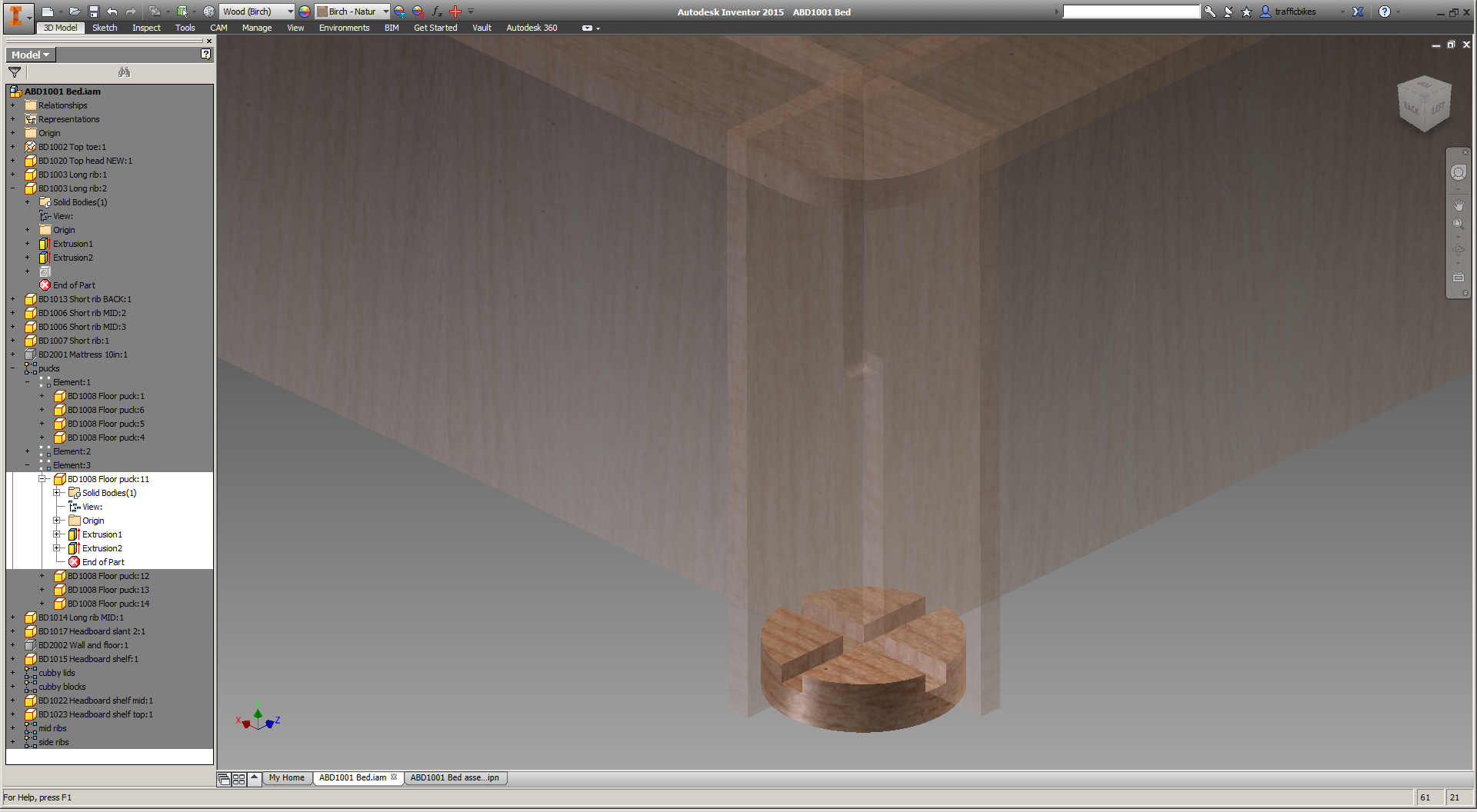

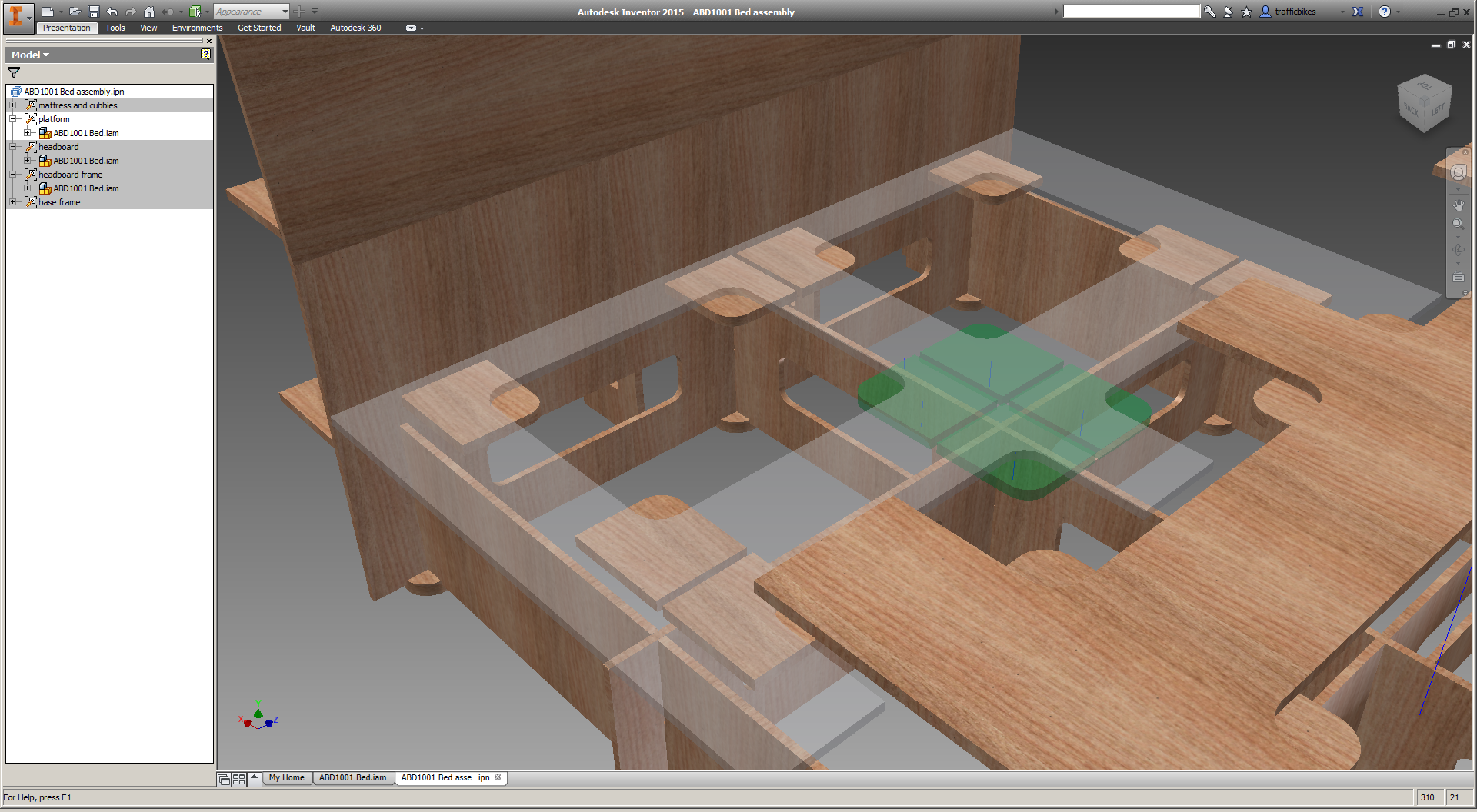

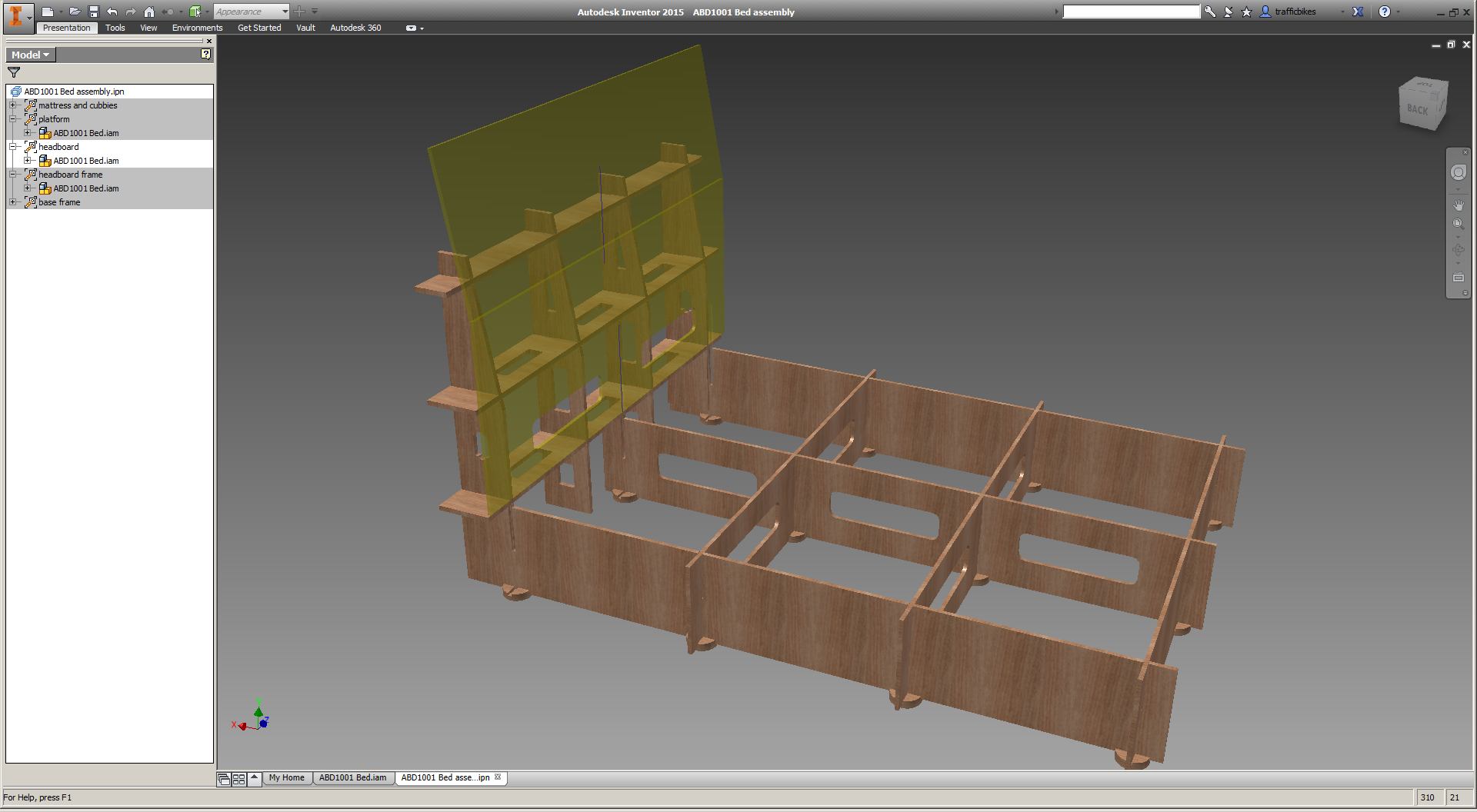

There are a few changes I'd make to the design. I hadn't thought the headboard hardware through completely, and need to add another set to the middle ribs. I also didn't get the slot depth exactly right - which doesn't matter for the platform but makes the headboard design non-optimal. This was kind of to be expected, as the endmill radius + a little slop + chamfered corners makes calculating it pretty tricky. It's *possible* that I'll redesign the headboard shelves to fix this, but so far it doesn't seem to matter too much.

Anyway, this project is mostly wrapped up at this point. Which feels great.

Plus, I got to put it to use immediately - and will be repeating that daily from here on out :)