This has been a long time coming.

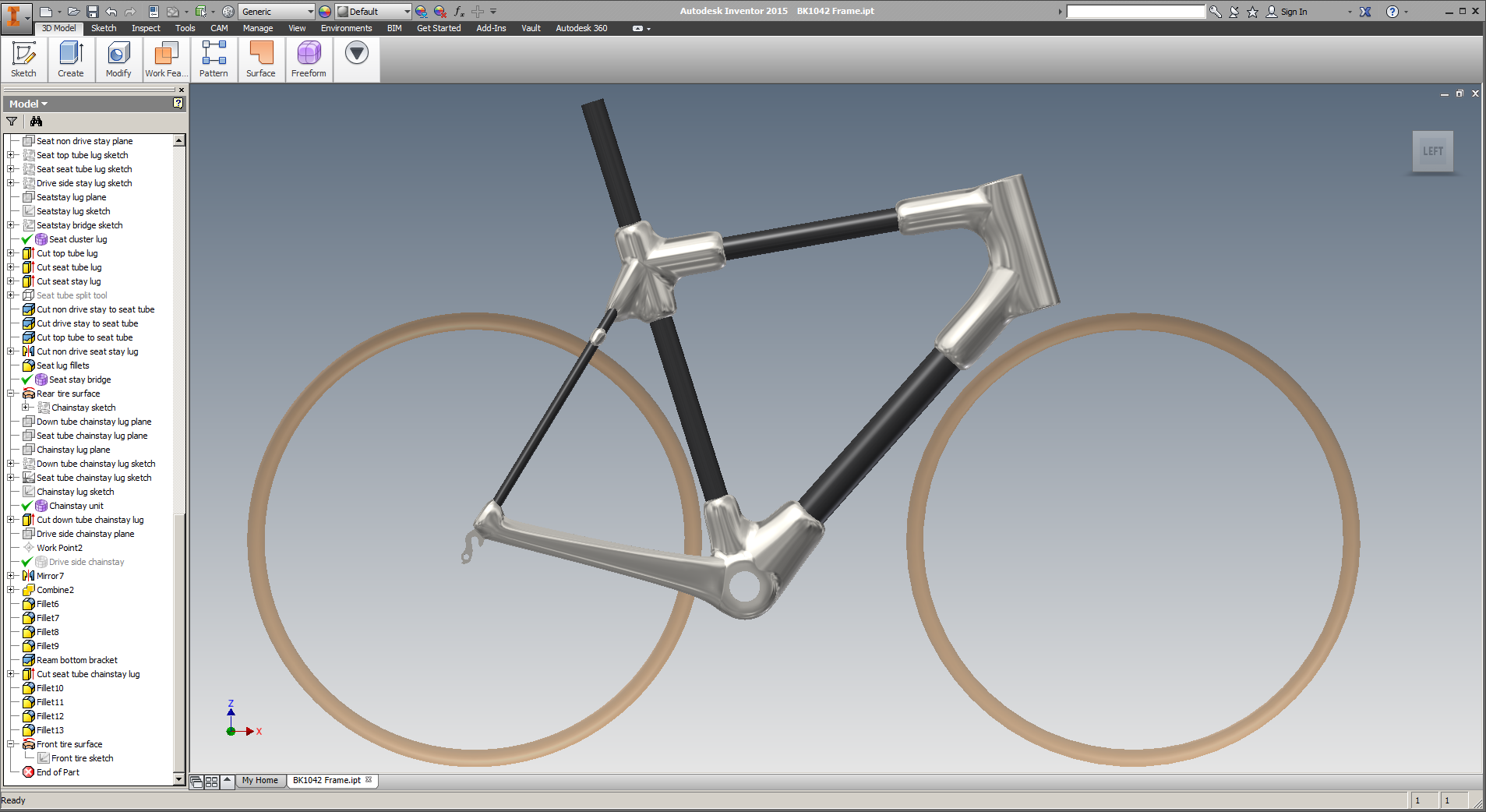

For what it's worth, I had the idea before either Triple Bottom Line or Bastion launched - but I'm fully aware that that doesn't buy me shit. At its core: build titanium 3D printed bike frame components, and use carbon fiber tubing for areas that are too big to practically print. This avoids the crazy crowded build chamber (and inefficient glue joints) that Renishaw/Empire's bike required, and utilizes AM for what it's good at - making customizable, low-mass parts that fit easily on a build plate.

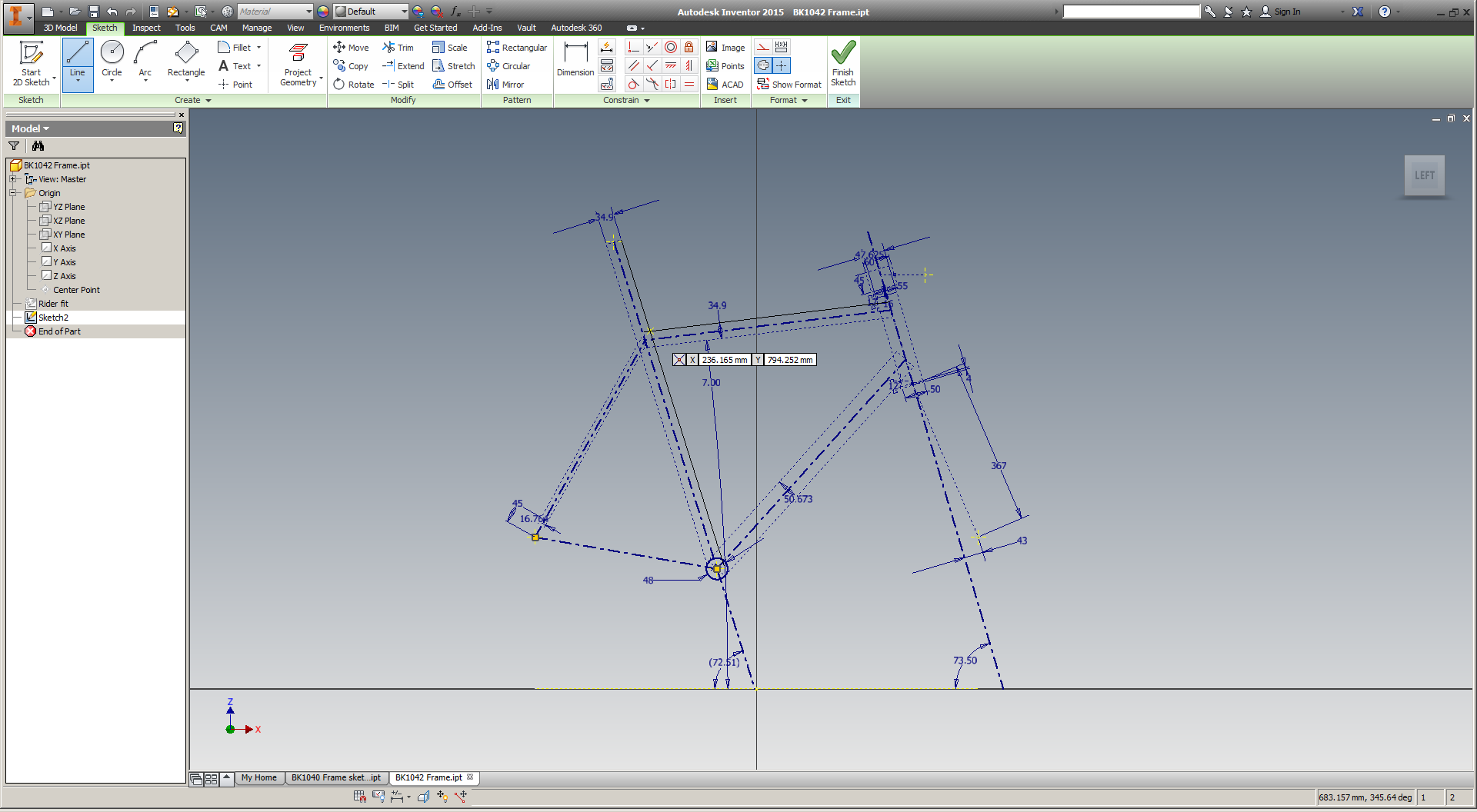

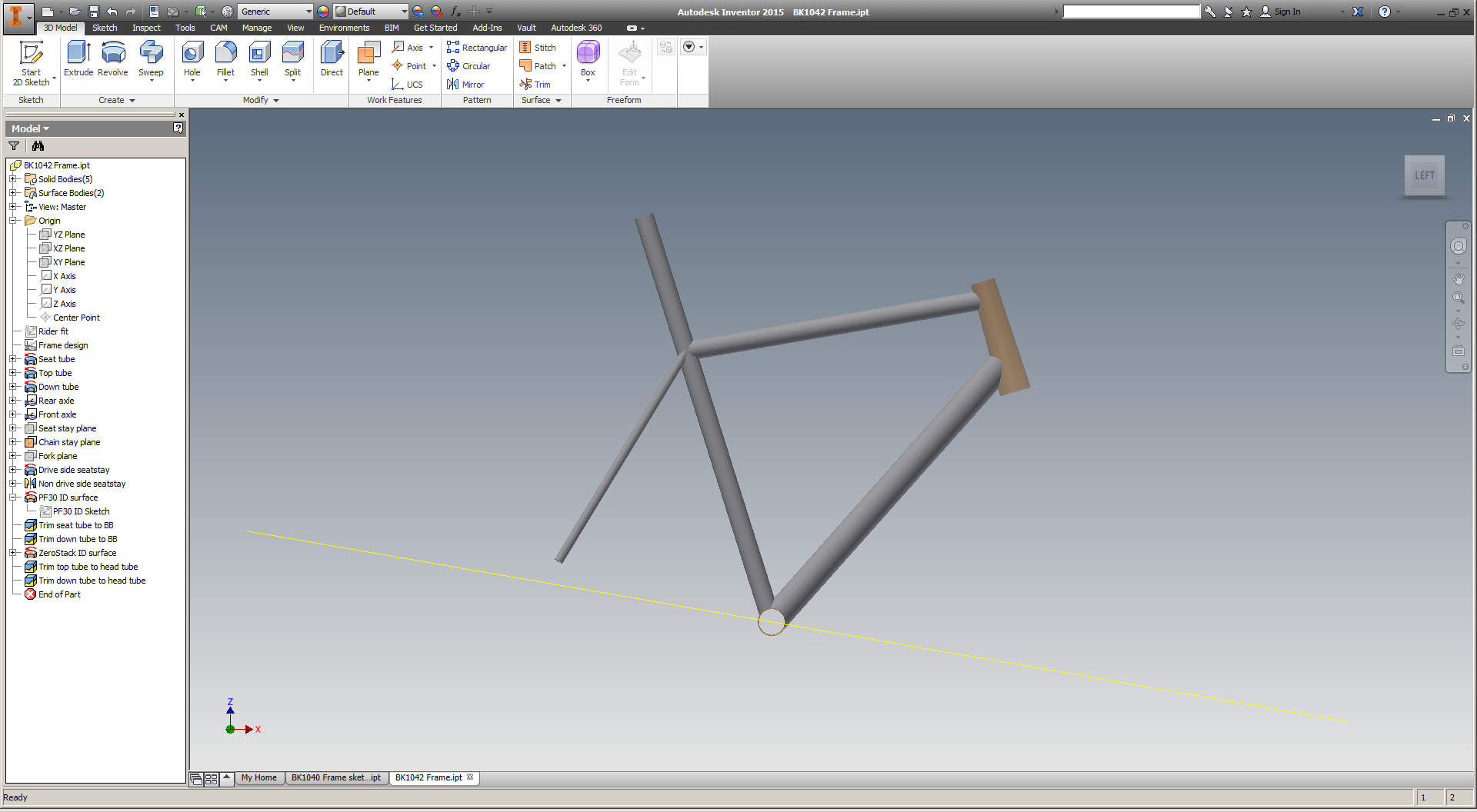

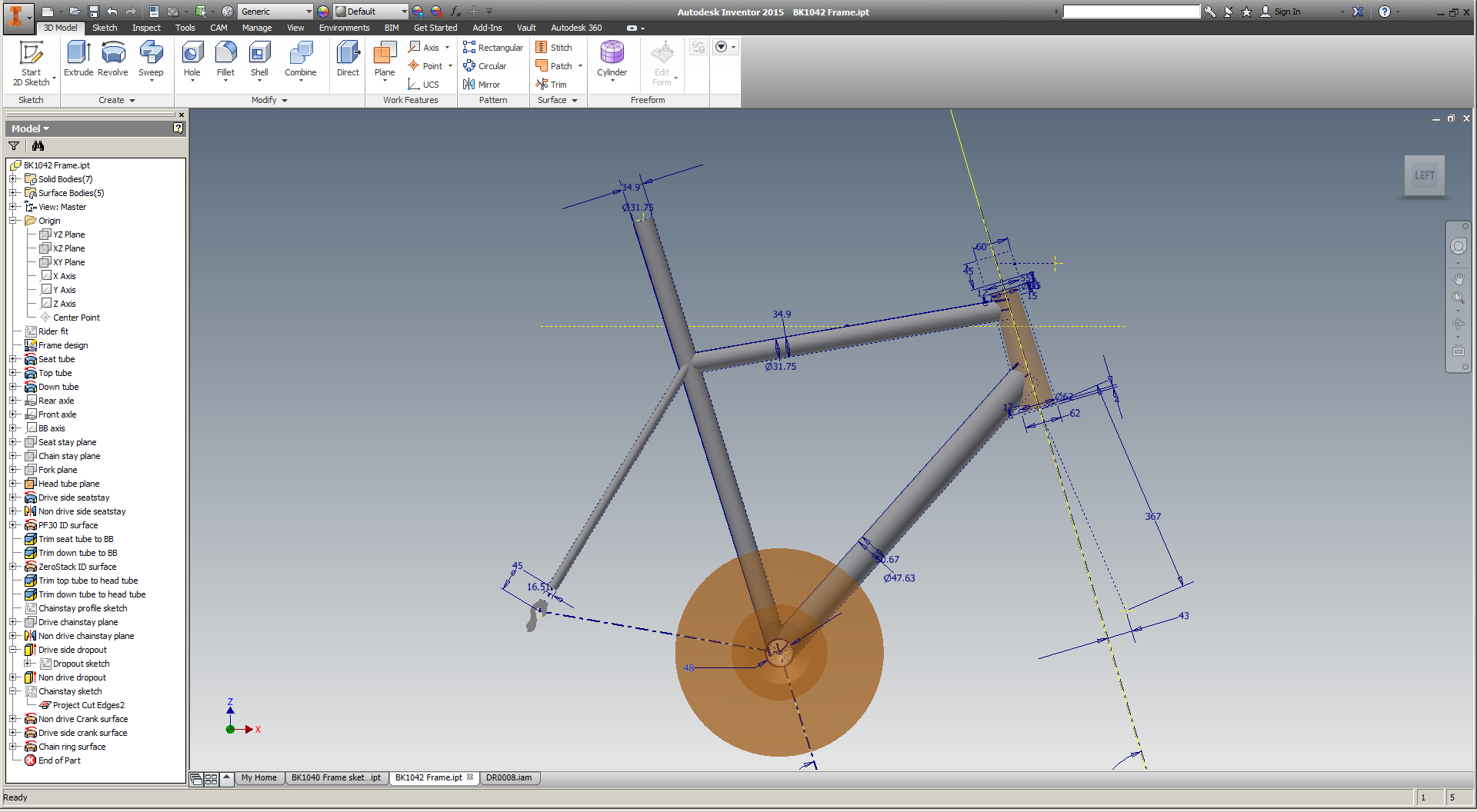

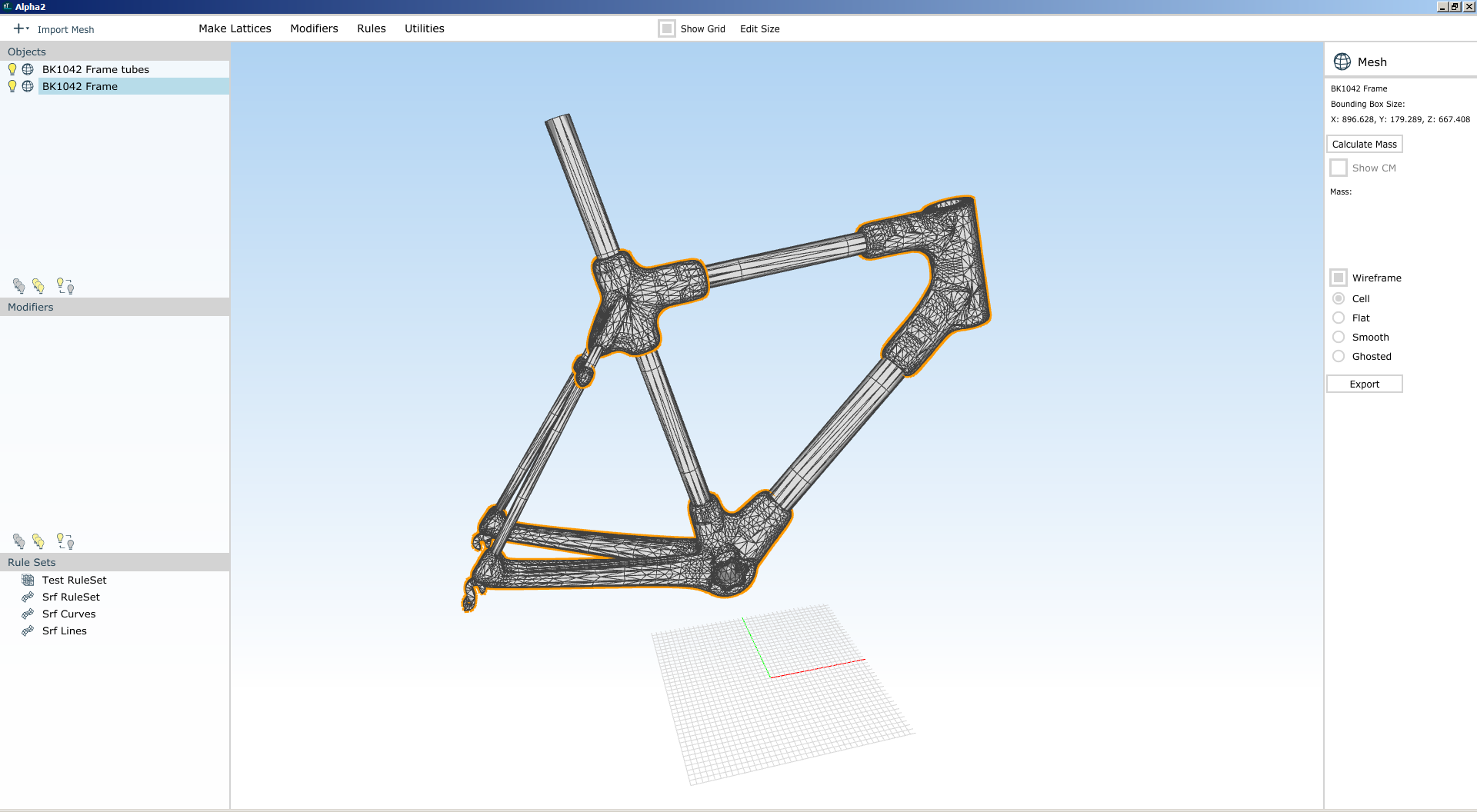

I thought about this for a *long* time, but only this week spent some time modeling my design spaces in Inventor and poking at the lattice generation process in nTopology Element. This is still far from manufacturable, but it was great to spend a day working through how to design and customize each design space in a way that was repeatable and simple.

In short, the frame would have four (or possibly three, if I integrate the brake bridge into the seat lug) printed titanium components; the rest is carbon fiber tubing. I'll likely also add a printed seatmast topper (probably with integrated saddle rails).

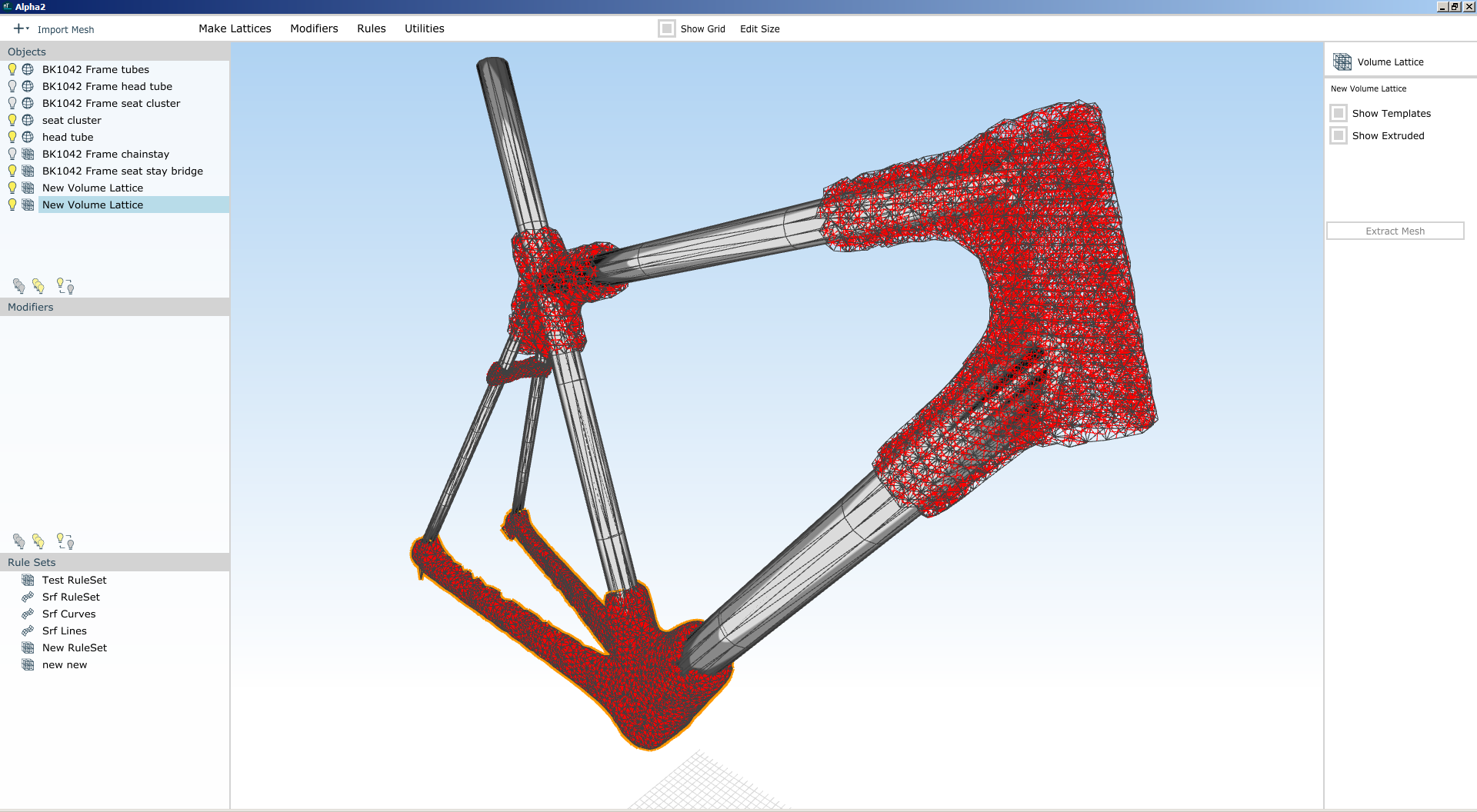

I spent a *tiny* amount of time setting up lattices for each printed component in nTopology Element today. This is extremely preliminary, but I really like the look and think that the basic idea - that the printed components are optimized for lattice shape and thickness, but in general never reach 100% density - is a good one.

You can *bet* that I'll be working on this more in the next week. Stay tuned :)