This is still happening.

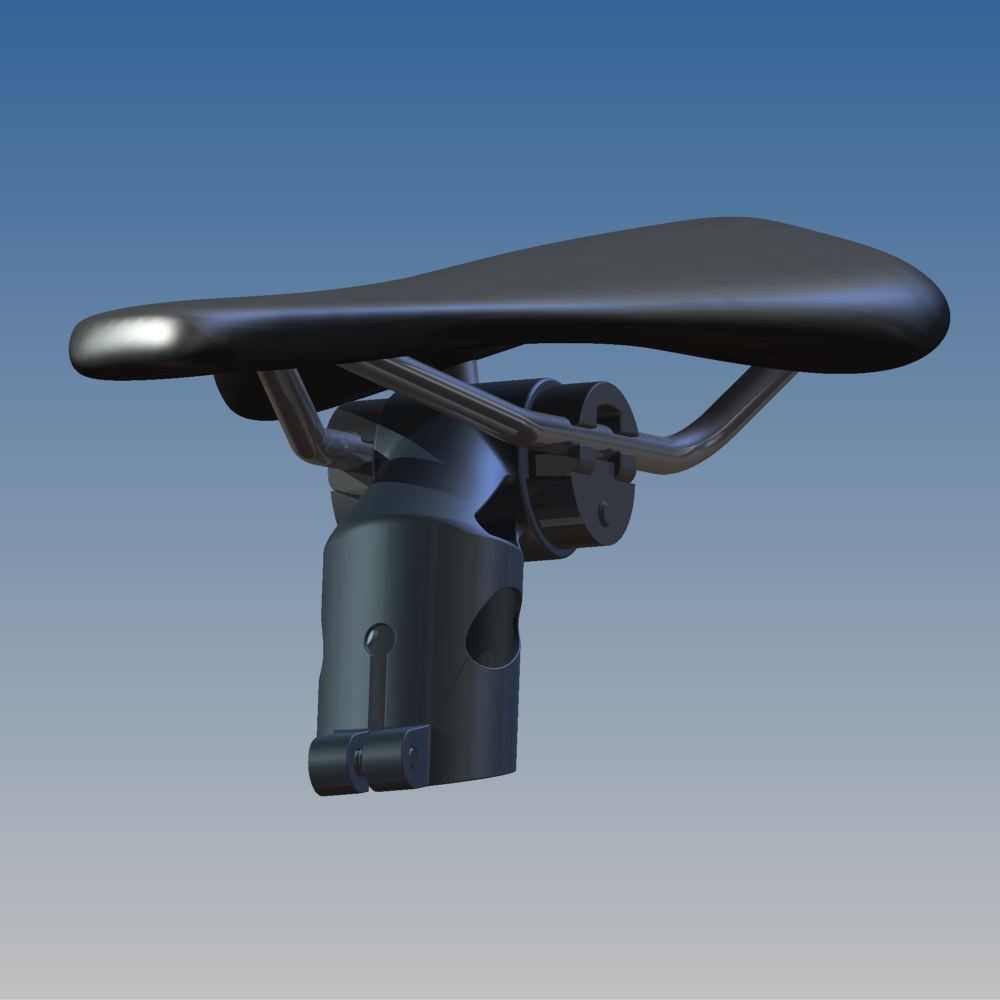

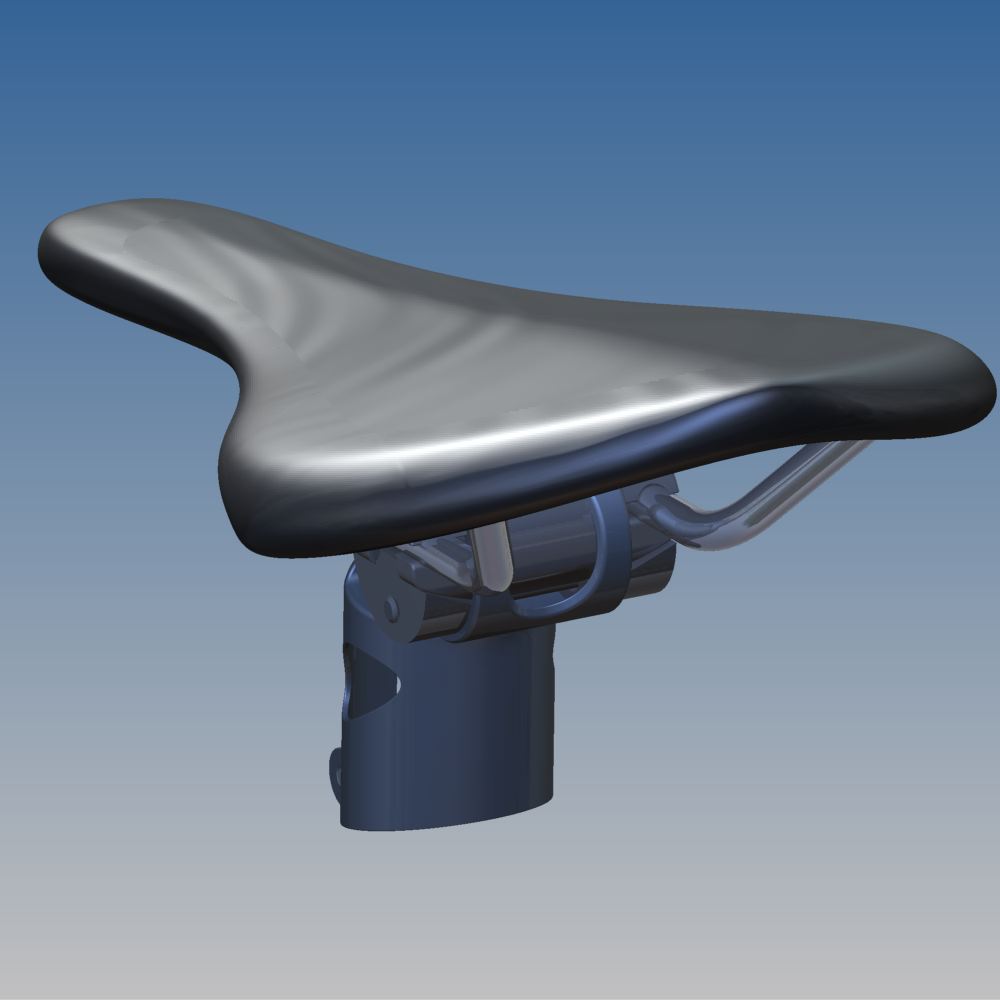

It's been slow, but my metal powder bed fusion (aka DMLS, LaserCUSING, selective laser sintering, etc.) seatmast topper is moving forward. With any luck, I'll have a part in production in a week's time.

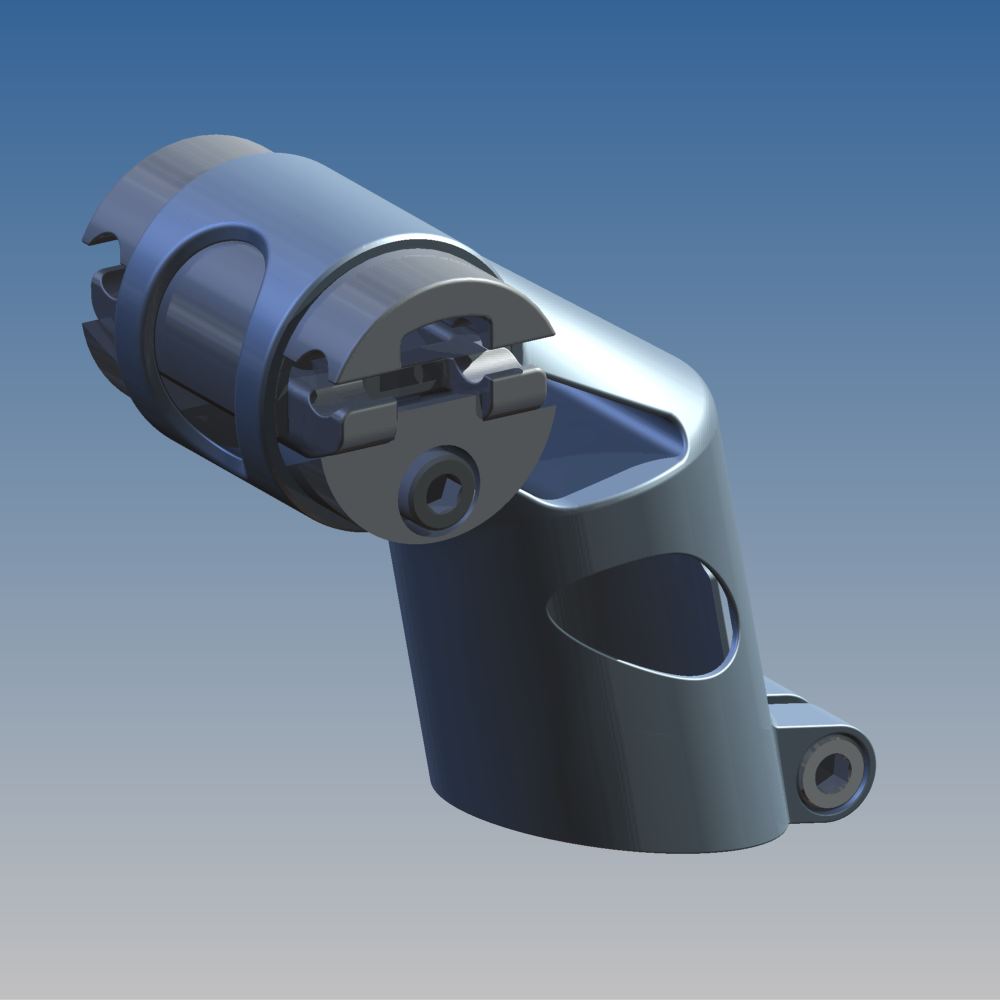

I've made some small changes to the design. The biggest thing is the hole in the back of the part, which is meant to reduce mass. I also modeled the threads in the clamp, which will help my manufacturer print the threads.

Choosing a job shop for this has been interesting. Since my post on DMLS pricing, I've had a bit of interest on my project. My hope has been that I'd be seen as more of a partner than a customer, but the extent of that remains to be seen. Selling a partnership is something I'm green at, and companies that deal mostly with corporate and institutional buyers don't necessarily think of investing time into a project that has an indirect upside.

Nonetheless, I think there's something to it. This project is partly product, partly experiment in advanced logistics. The information I'm learning on the subject is free for anyone to see, but the partners that I'll end up working with will develop unique experience working on a thin-wall, consumer facing part. There aren't a ton of people working on that kind of thing, but I expect that'll change in the near future. My hope would be that my partners would agree with me, and would see this project as an opportunity to develop additional capabilities at a relatively low expense.

Nevertheless, I'm determined. And I'm looking forward to having a piece of laser sintered titanium in my hands, too :)