This is a fairly big deal to me. The overall numbers are small relative to what can happen when web startups launch, but the quick jump in viewership of our product - this fucking *thing* that we've been working on for so long - is real a kick. In the past, my web presence has taken a much longer time to develop. TCD spent years in the dark corners of the internet, and this site has bumped along as well, growing slowly over time. But The Public Radio is a product that a certain type of person just gets, and we've stumbled upon a handful of those people.

The best part has been seeing the Mailchimp roster grow, and noticing "@npr.org" pop up way more than we had expected. It makes sense, of course - we got a few public radio folks checking us out, and they must have shared it with colleagues - but it's still a bit of a trip to see it actually happen.

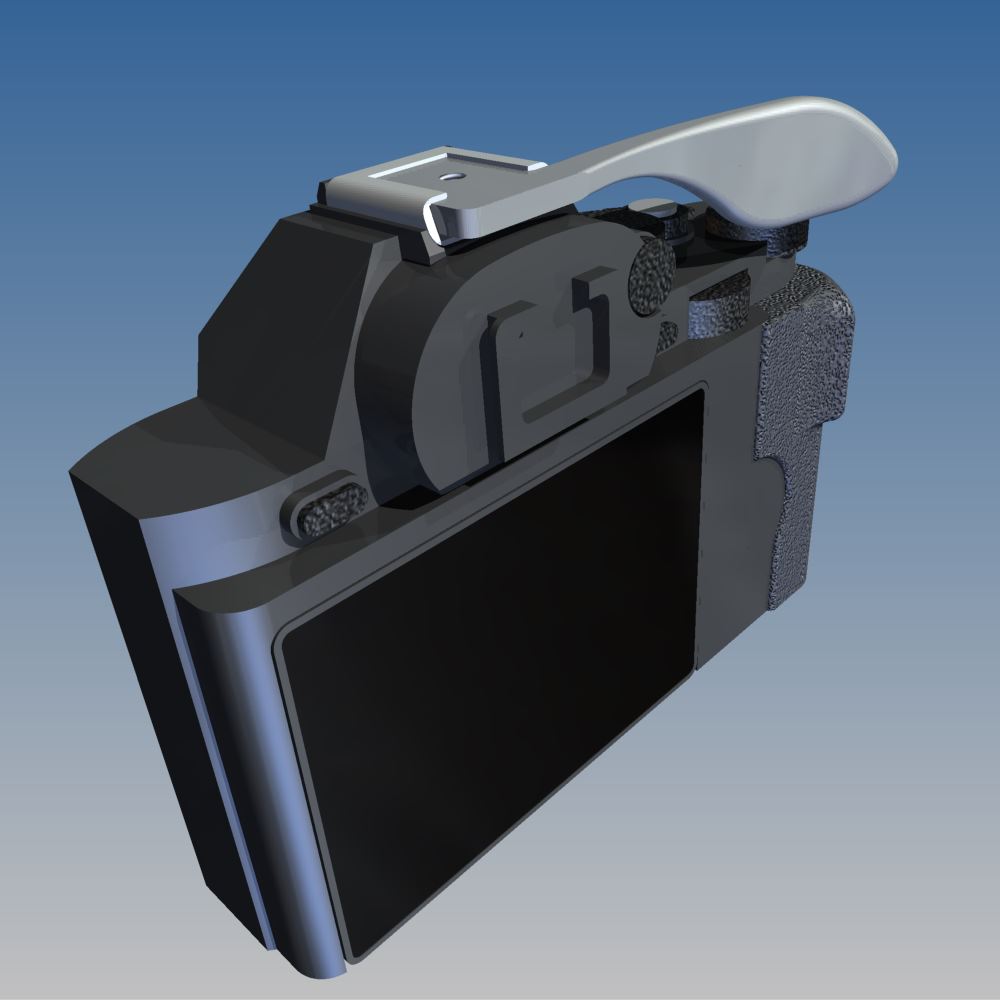

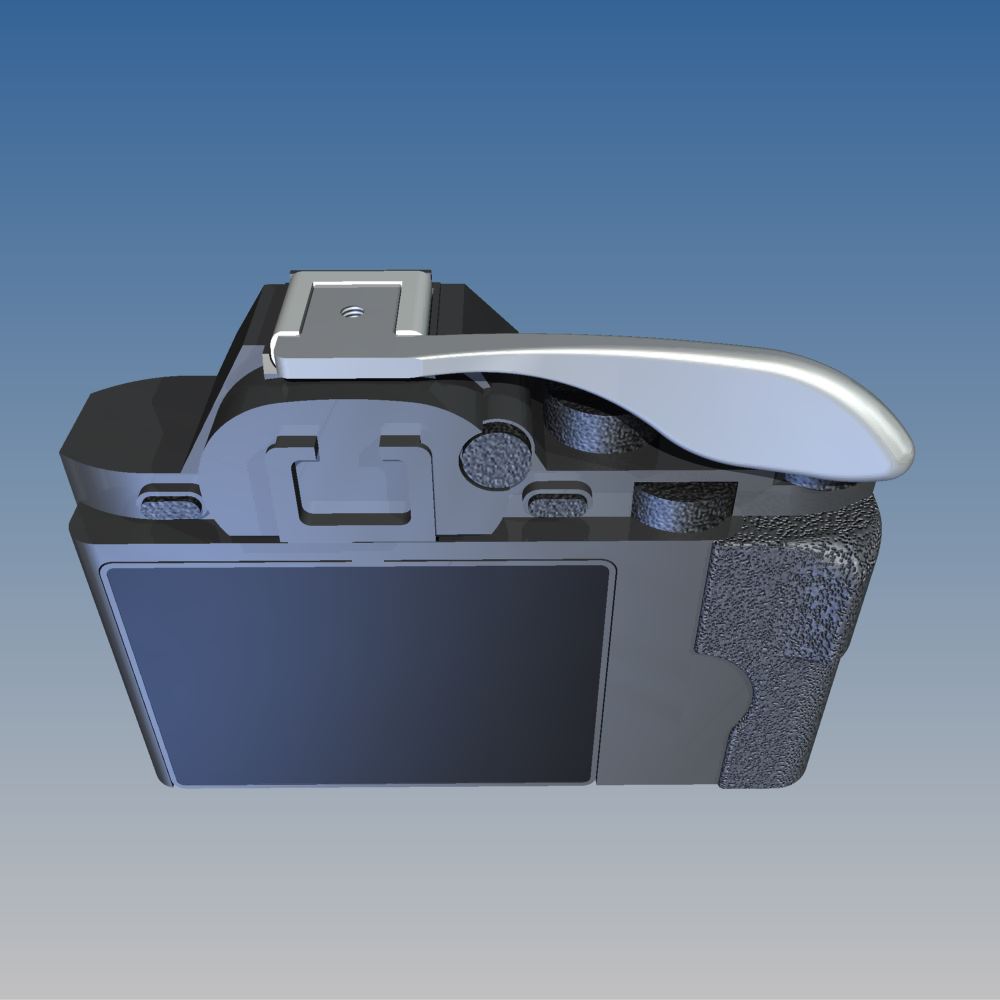

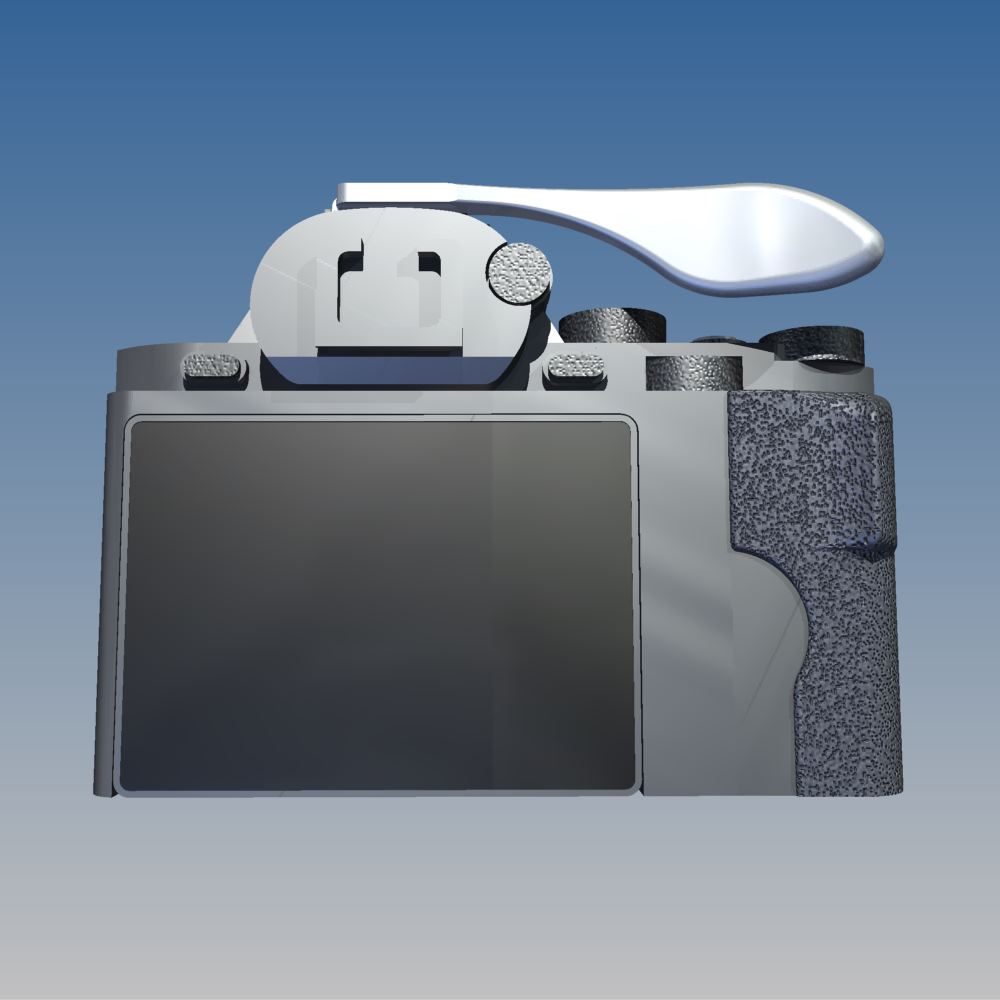

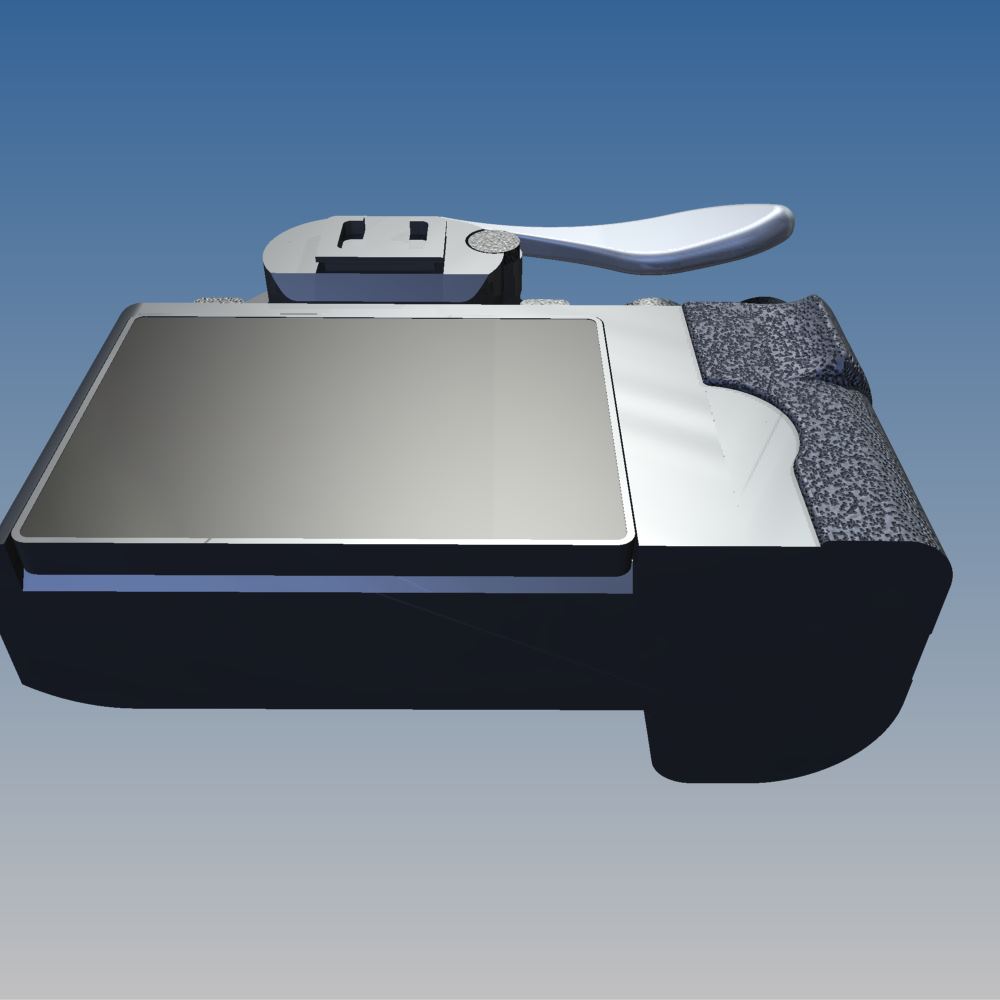

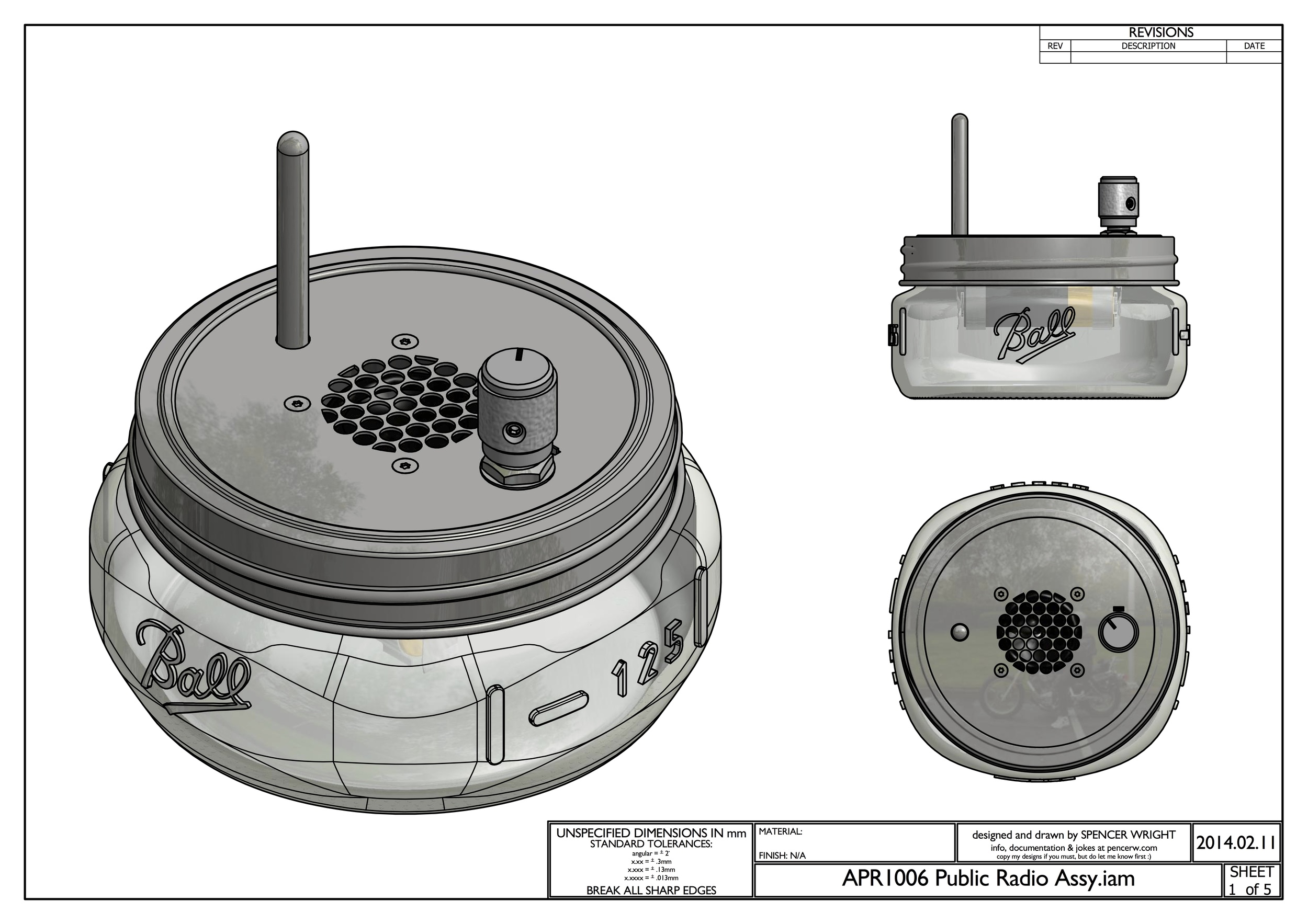

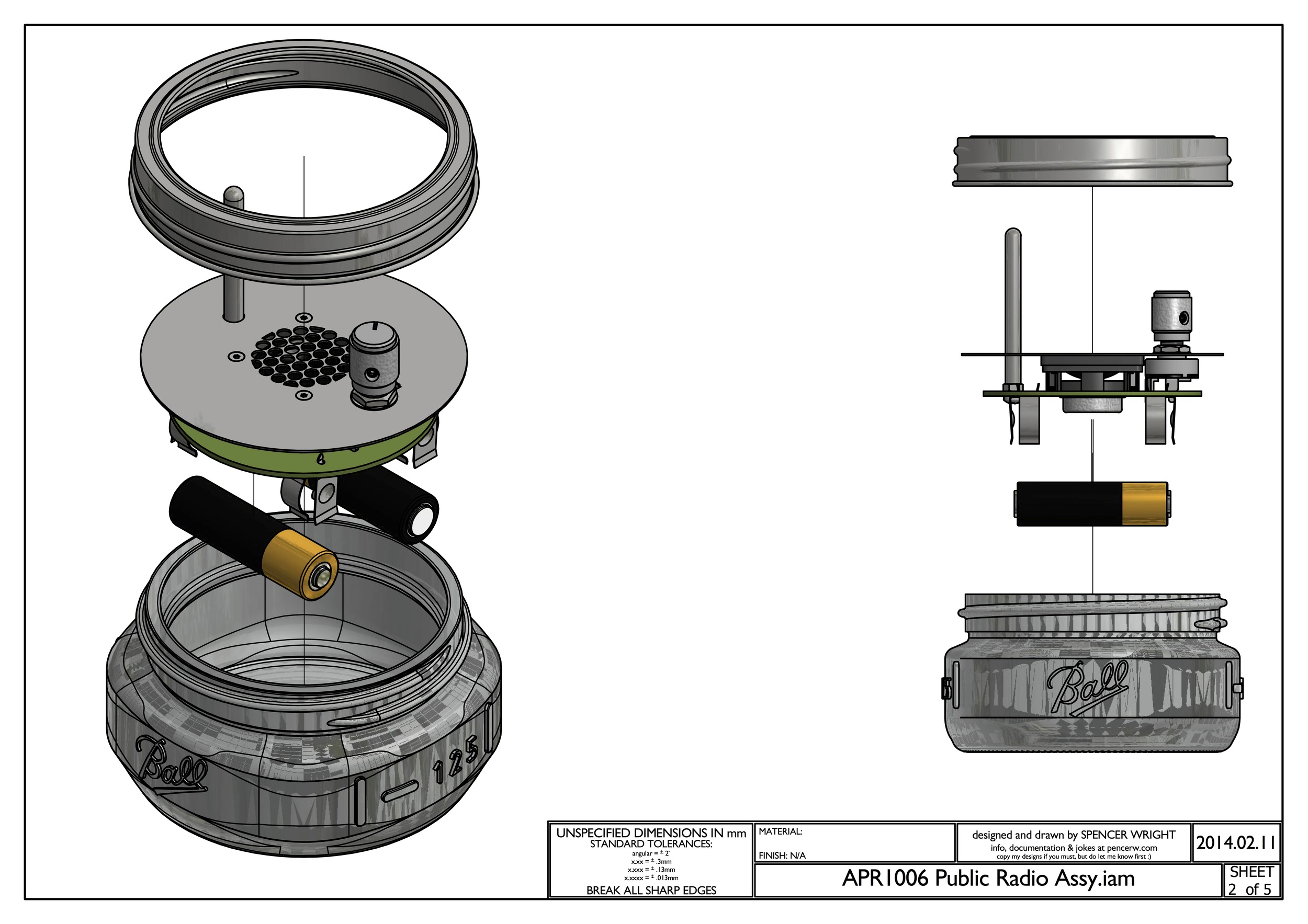

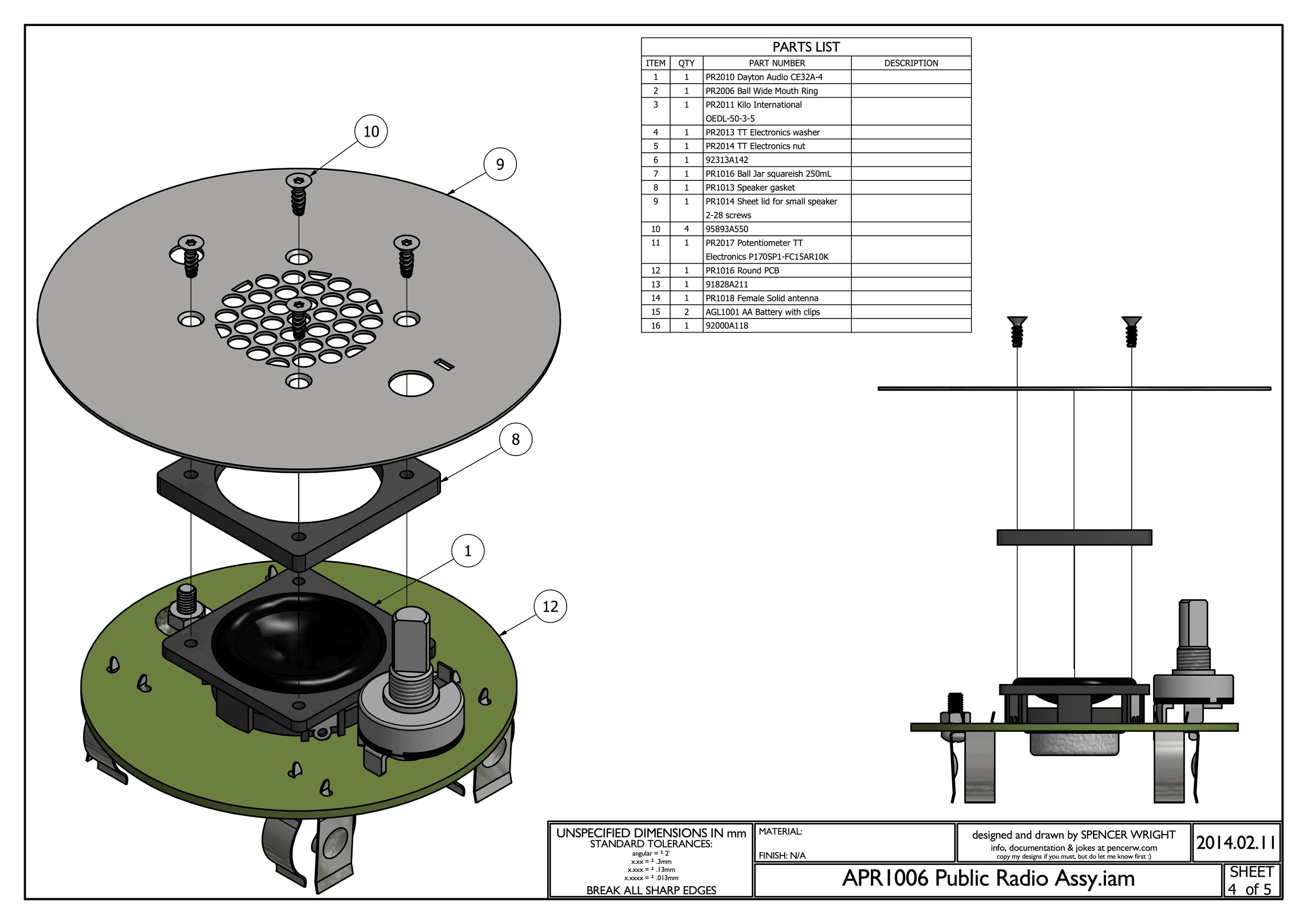

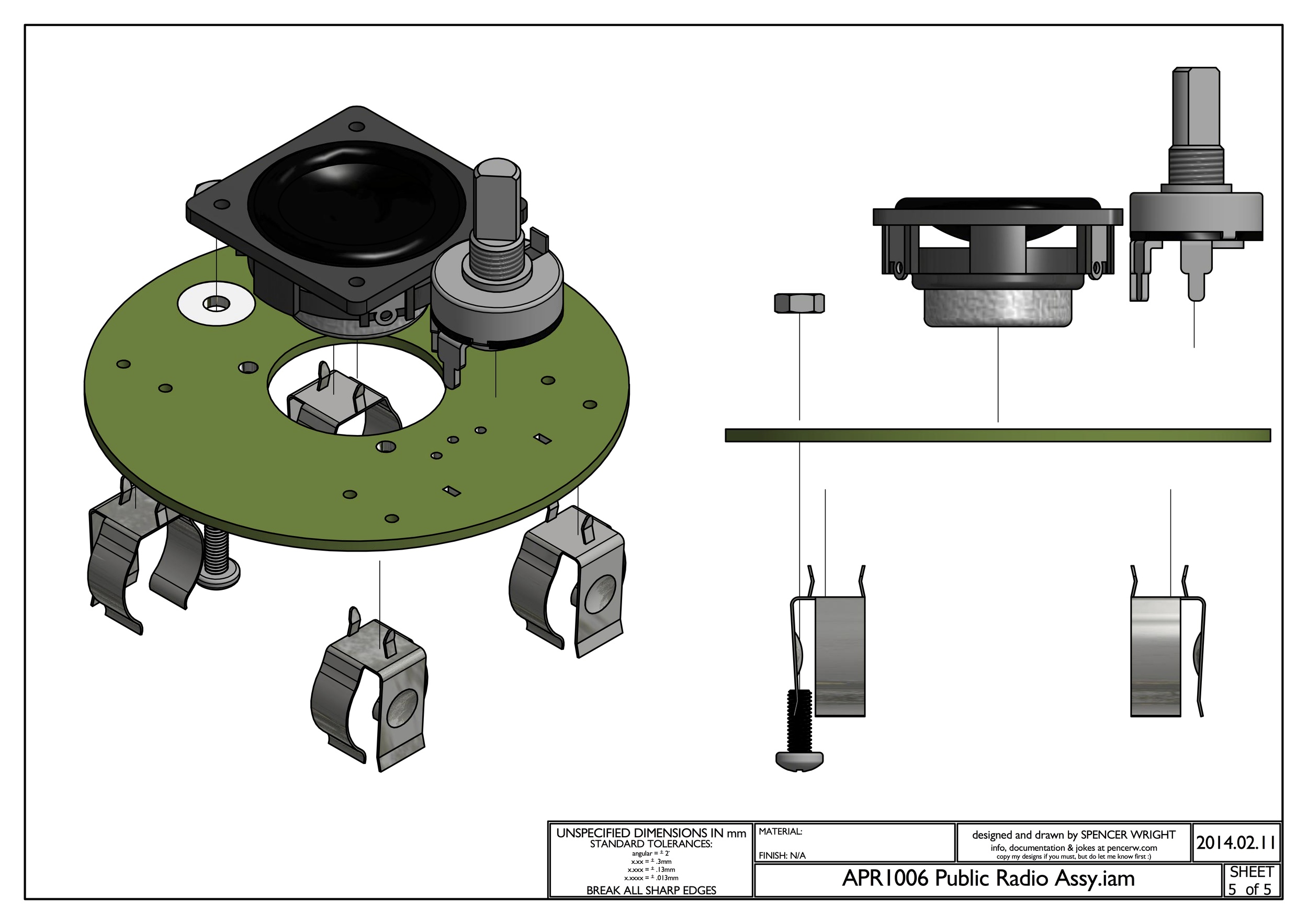

This next few weeks should be fun. We've got PCBs showing up from China in about two weeks, and I'll probably order prototype quantities of antennae ( :/ ) and lids tomorrow too. Our BOM is basically complete, and the majority of our engineering work is done, and so now is the time to really work on understanding our customers & suppliers.

On that note: We're actively pursuing partnerships with NPR and affiliate stations for The Public Radio. We think it would be a great fund drive gift for any station, and would love to be put in touch with anyone working in FM radio, public or private. If you're reading this and know someone in radio, I'd love an intro.

We're also looking around for advance press coverage, so send me your ideas on those as well. And feel free to share! We love the attention :)

February is shaping up to be fun :)