This blew my mind!

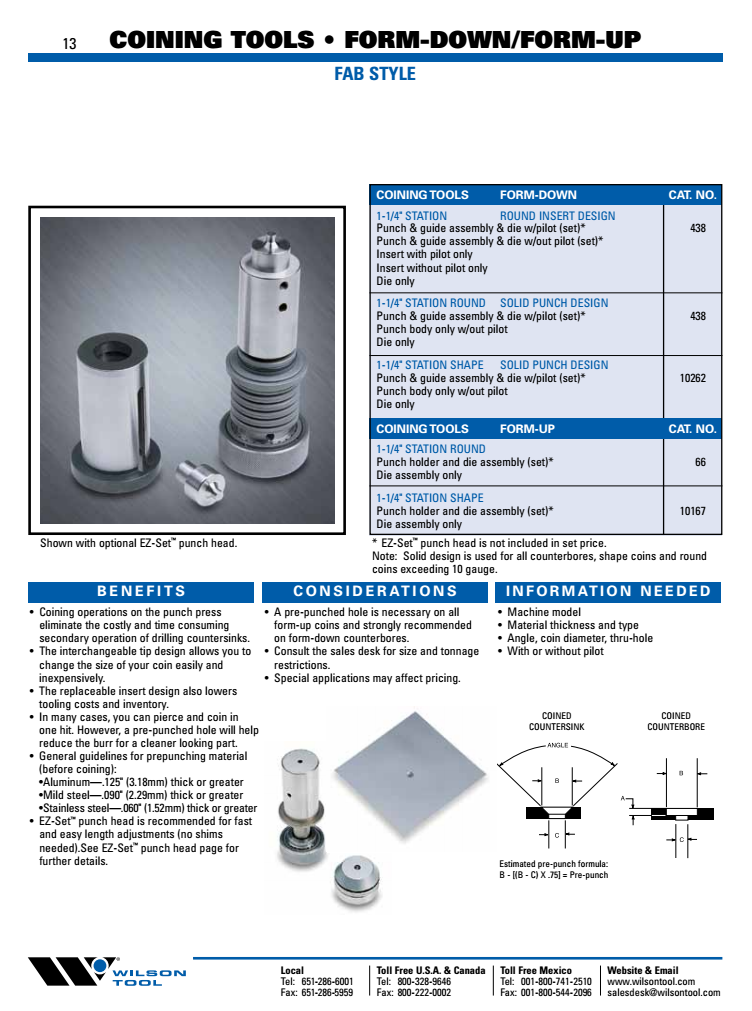

A supplier of The Public Radio's stamped lid sent me a catalog of stamping tools, and I took a little while looking though it. This page set me on a google wormhole:

They're talking here about cold working countersink features in sheet metal. The hole is pre-punched and then worked with a tool that moves material around to create a countersink.

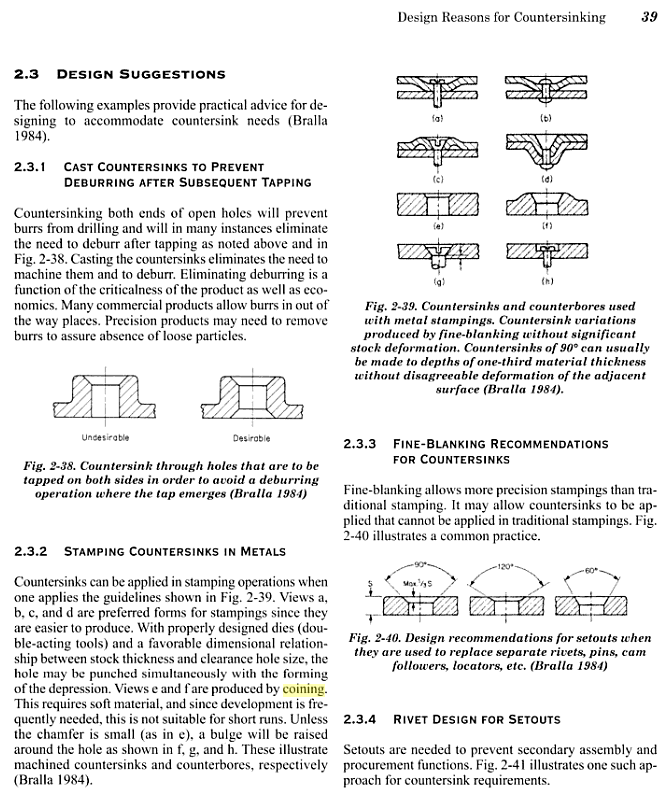

This process probably isn't right for The Public Radio - it requires thicker material than we're using - but it's really cool. I googled around a bit and found a textbook on countersinks, which describes a bunch of sheet metal features that I was unaware of:

It would be really fun to explore these. Stamping is really economical at scale, and knowing all the ways it can be used is super interesting.