Camera

Kern schmern

I'm mostly just posting this to give Jonathan Bobrow, who created the kernel of The Public Radio's logo, a shout out. Anything I've done on top of his original work is, I'm sure, to our detriment.

Anyway, I spent a little while kerning today. Cause hey, someone's gotta do it.

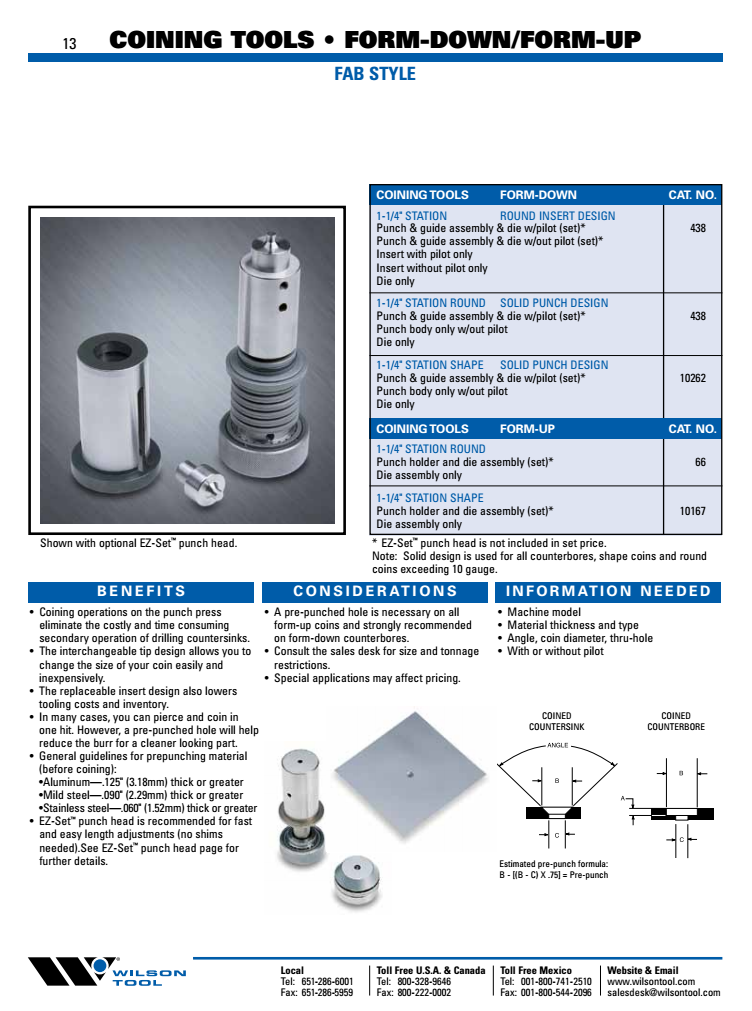

Coined Countersinks

This blew my mind!

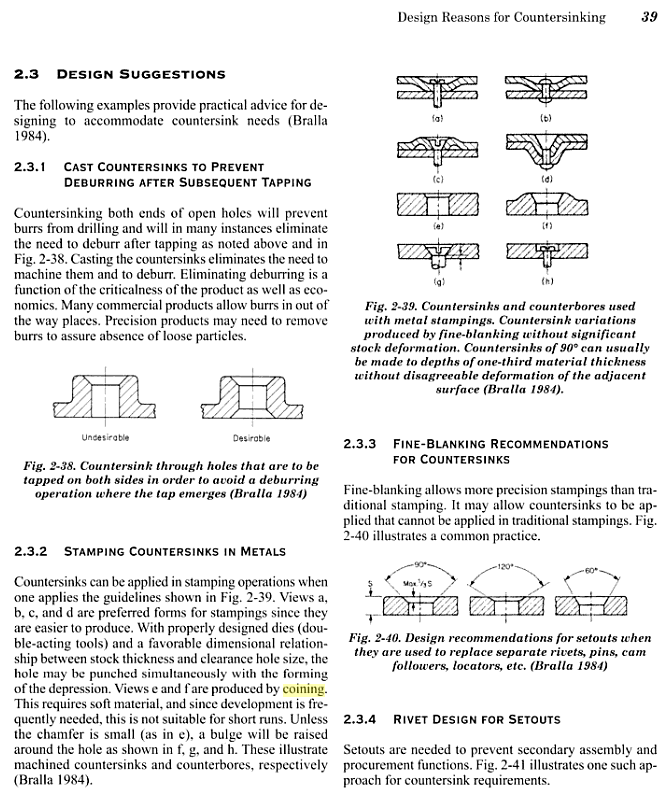

A supplier of The Public Radio's stamped lid sent me a catalog of stamping tools, and I took a little while looking though it. This page set me on a google wormhole:

They're talking here about cold working countersink features in sheet metal. The hole is pre-punched and then worked with a tool that moves material around to create a countersink.

This process probably isn't right for The Public Radio - it requires thicker material than we're using - but it's really cool. I googled around a bit and found a textbook on countersinks, which describes a bunch of sheet metal features that I was unaware of:

It would be really fun to explore these. Stamping is really economical at scale, and knowing all the ways it can be used is super interesting.

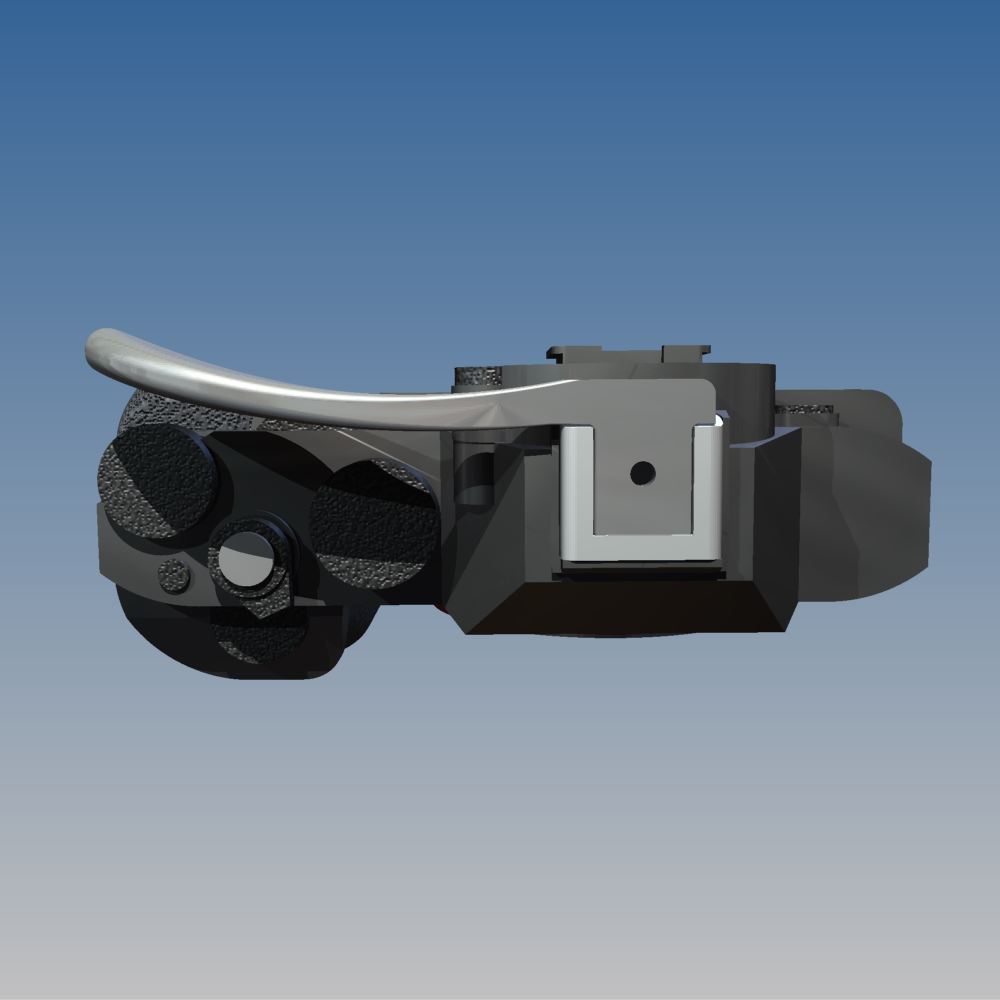

I wish I still had this mockup

From mid 2010:

This looks simple but there's a lot going on.

The handle itself is 7 or 8 pieces; this mockup shows it mounted to an assembly of extrusions (all of which I designed, and clad in blackened mahogany) which together make up the stile of a 2000lb swinging door. In the close corner you can actually see the inflatable pneumatic seal (I can't stress how cool this is) that keeps the door weatherproof from the exterior.

The handle has a couple of stainless steel mounting brackets which are hidden inside the stile. Then there are the horizontal parts, which are drilled internally to allow a bundle of wires to be routed from the stile into the handle itself. The vertical part of the handle is actually split along its long dimension, though you can't see it in the photo. The part on the right is solid, but the part on the left (towards the stile) rides on a couple of shafts and actuates about 1/16". When you grab the handle, the moving part clicks in just a little bit and closes a pair of tactile switches, which tell the door's brain (a custom ATMega board) that someone wants to be let out. That in turn deflates the pneumatic seal and releases a couple of electromagnets, unlocking the door.

If you followed any of that, kudos.

Anyway it's fucking cool. Too bad it never got built - it took me months to design & prototype.

Sure was a fun project, though.

Typical.

I try to sit in the kitchen with Zach & Libo, but sometimes I need to move to my desktop to do 3D stuff.

From the Archives: Carl Andre

I drew this in 2006, when I visited MoMA; the text is a word for word copy of the placard accompanying "144 Lead Square". I still feel deeply conflicted about MoMA & Andre's description of the intent of the work, especially vis a vis the last sentence.

But I do rather enjoy my transcription & doodle as meta-art :/

Graphs that go "like this: /"

Well, it's official: The Public Radio soft-launched yesterday. And we even did it with a clever domain name (I think):

It's not as if I've got a ton of direct experience performing any of the tasks that Zach and I have managed over the past six months, but there's been something striking to me about the past two days. It's this:

This is a fairly big deal to me. The overall numbers are small relative to what can happen when web startups launch, but the quick jump in viewership of our product - this fucking *thing* that we've been working on for so long - is real a kick. In the past, my web presence has taken a much longer time to develop. TCD spent years in the dark corners of the internet, and this site has bumped along as well, growing slowly over time. But The Public Radio is a product that a certain type of person just gets, and we've stumbled upon a handful of those people.

The best part has been seeing the Mailchimp roster grow, and noticing "@npr.org" pop up way more than we had expected. It makes sense, of course - we got a few public radio folks checking us out, and they must have shared it with colleagues - but it's still a bit of a trip to see it actually happen.

This next few weeks should be fun. We've got PCBs showing up from China in about two weeks, and I'll probably order prototype quantities of antennae ( :/ ) and lids tomorrow too. Our BOM is basically complete, and the majority of our engineering work is done, and so now is the time to really work on understanding our customers & suppliers.

On that note: We're actively pursuing partnerships with NPR and affiliate stations for The Public Radio. We think it would be a great fund drive gift for any station, and would love to be put in touch with anyone working in FM radio, public or private. If you're reading this and know someone in radio, I'd love an intro.

We're also looking around for advance press coverage, so send me your ideas on those as well. And feel free to share! We love the attention :)

February is shaping up to be fun :)

Old Glue.

This was a long time ago, when I ordered an in-depth investigation of what adhesives to use to bond mahogany to anodized aluminum. This entrant was not the winner.

This is actually what my desk looks like.

I love this. A few inches away are a stack of custom PCBs, too :)

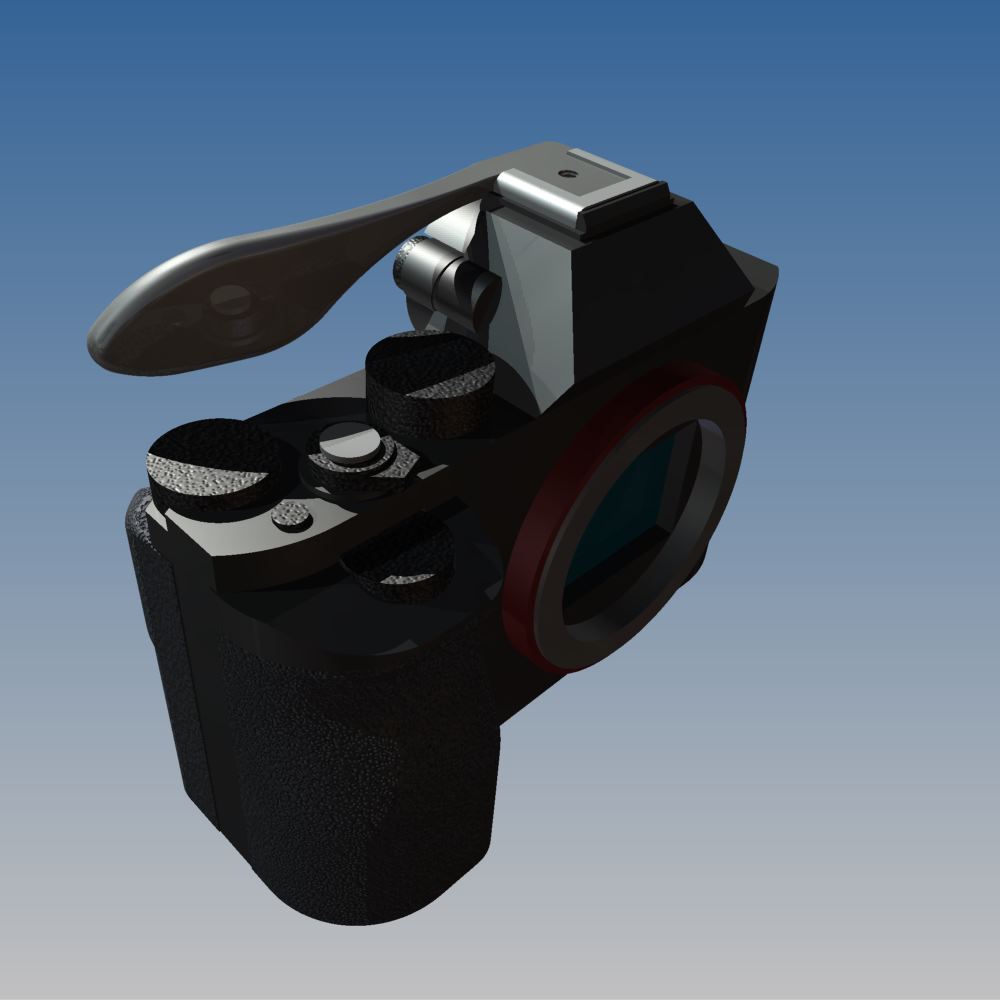

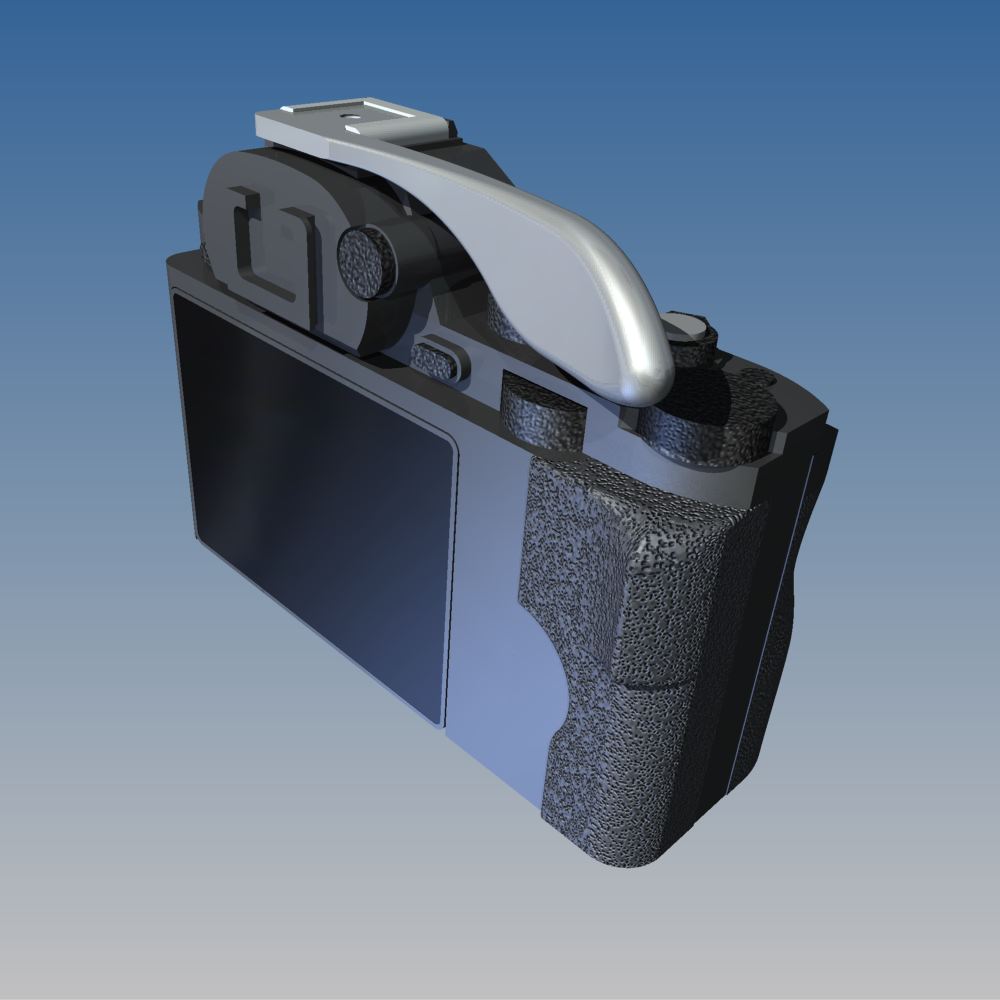

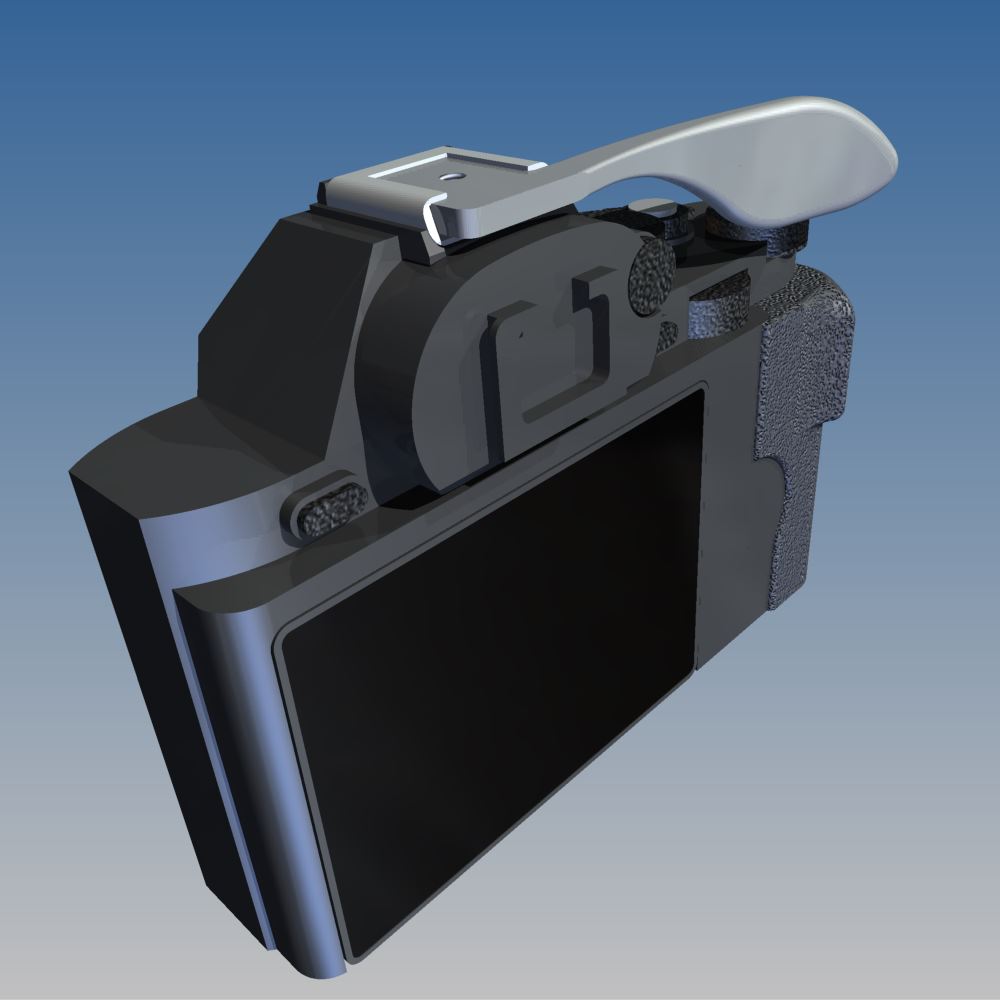

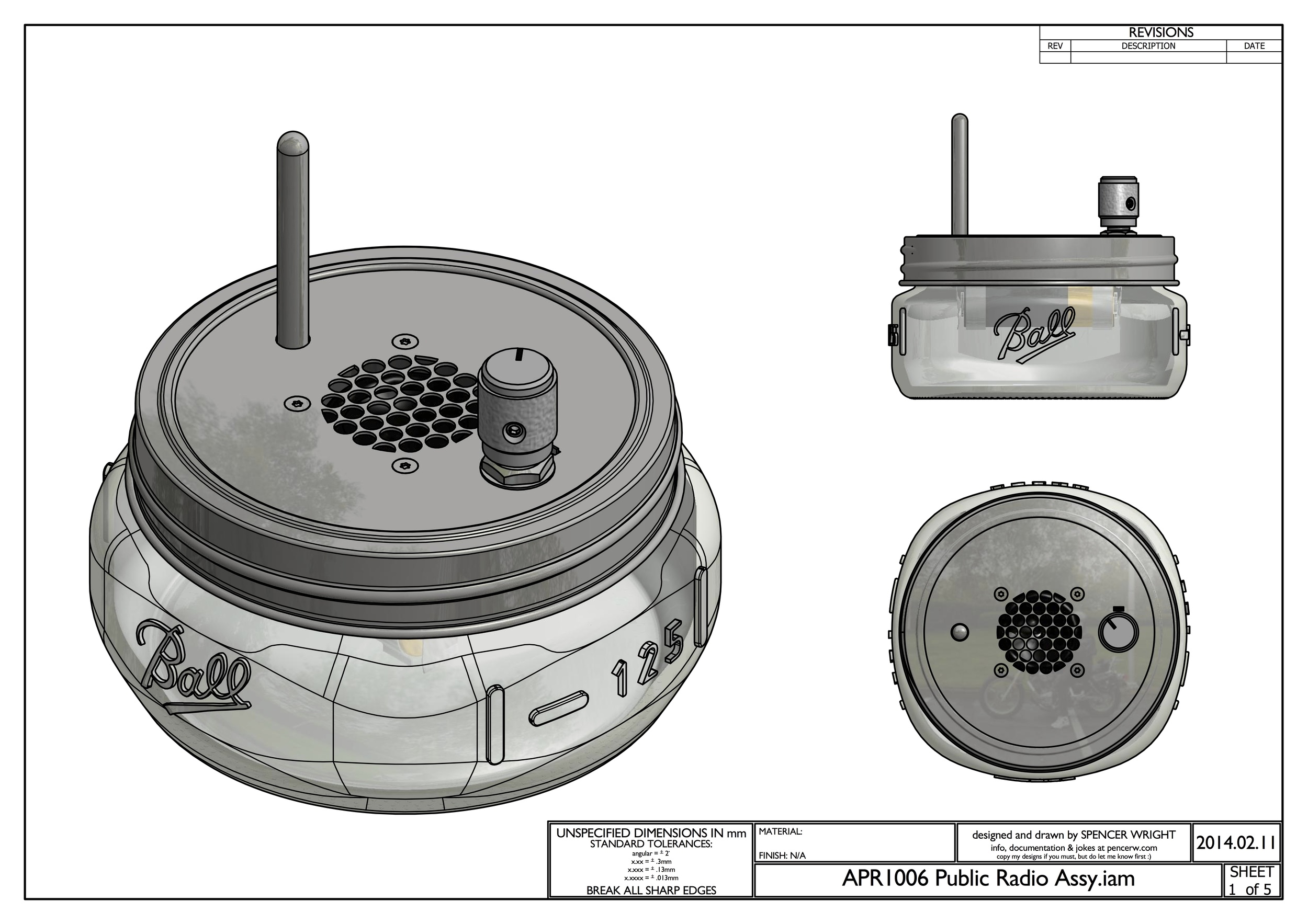

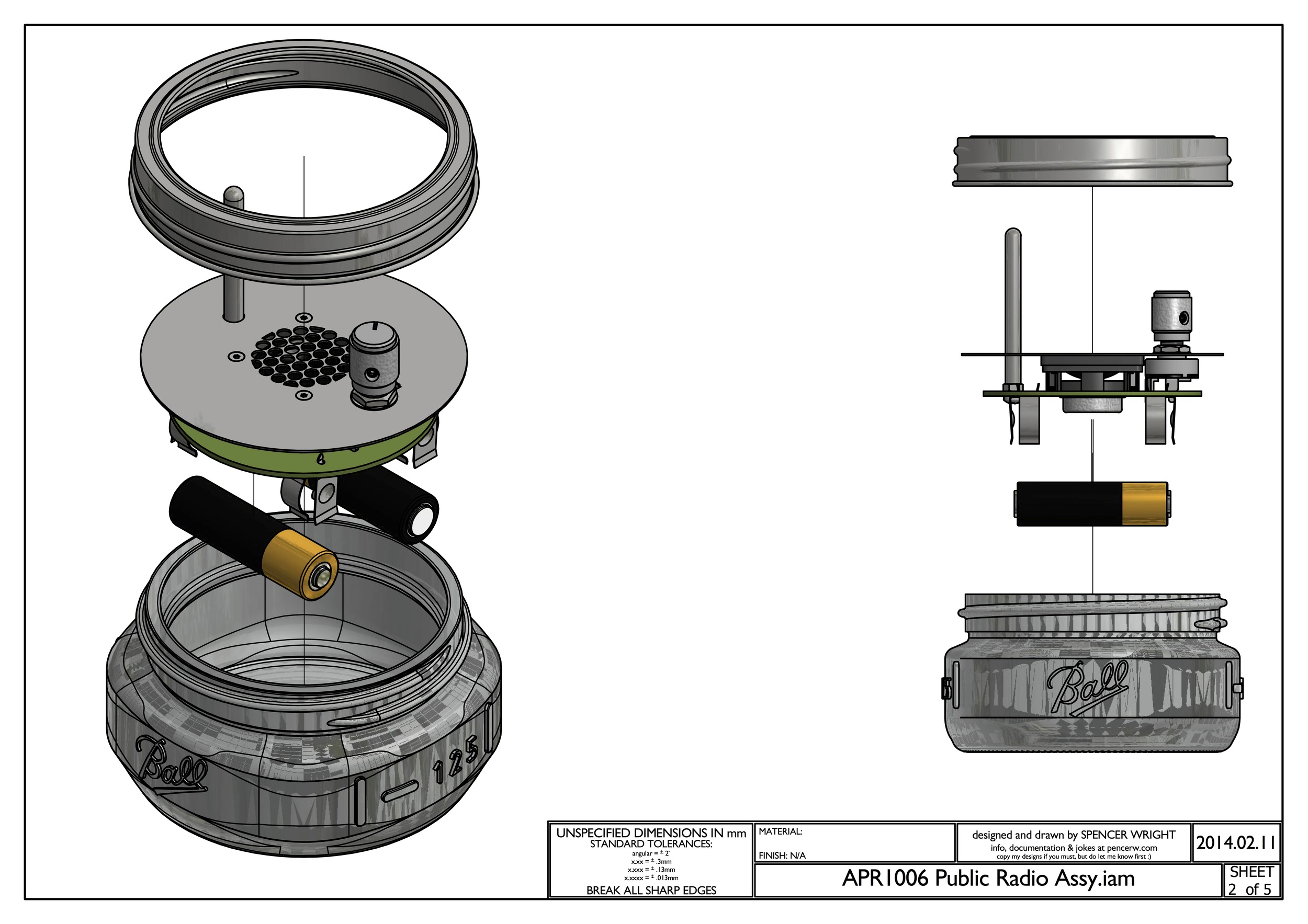

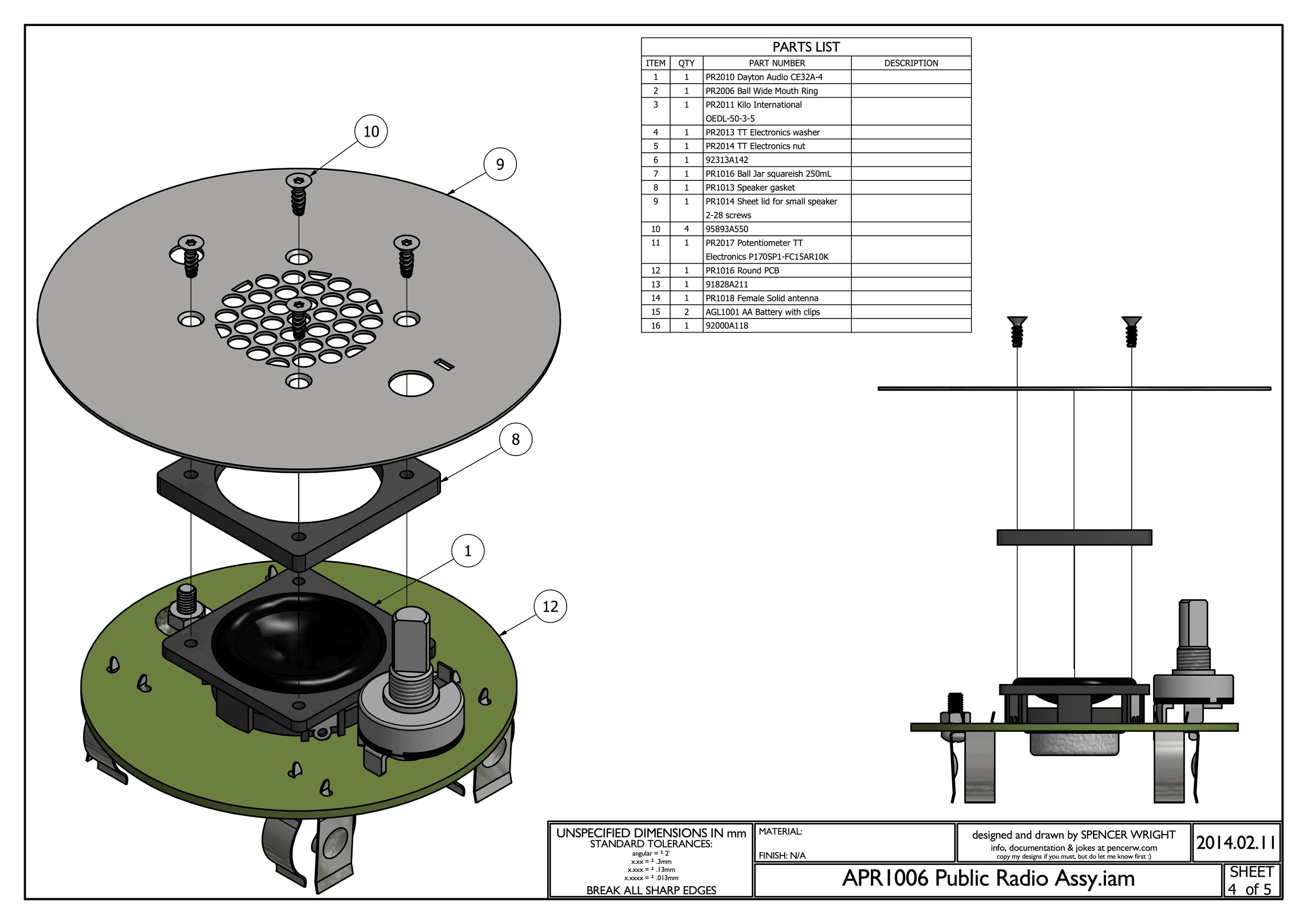

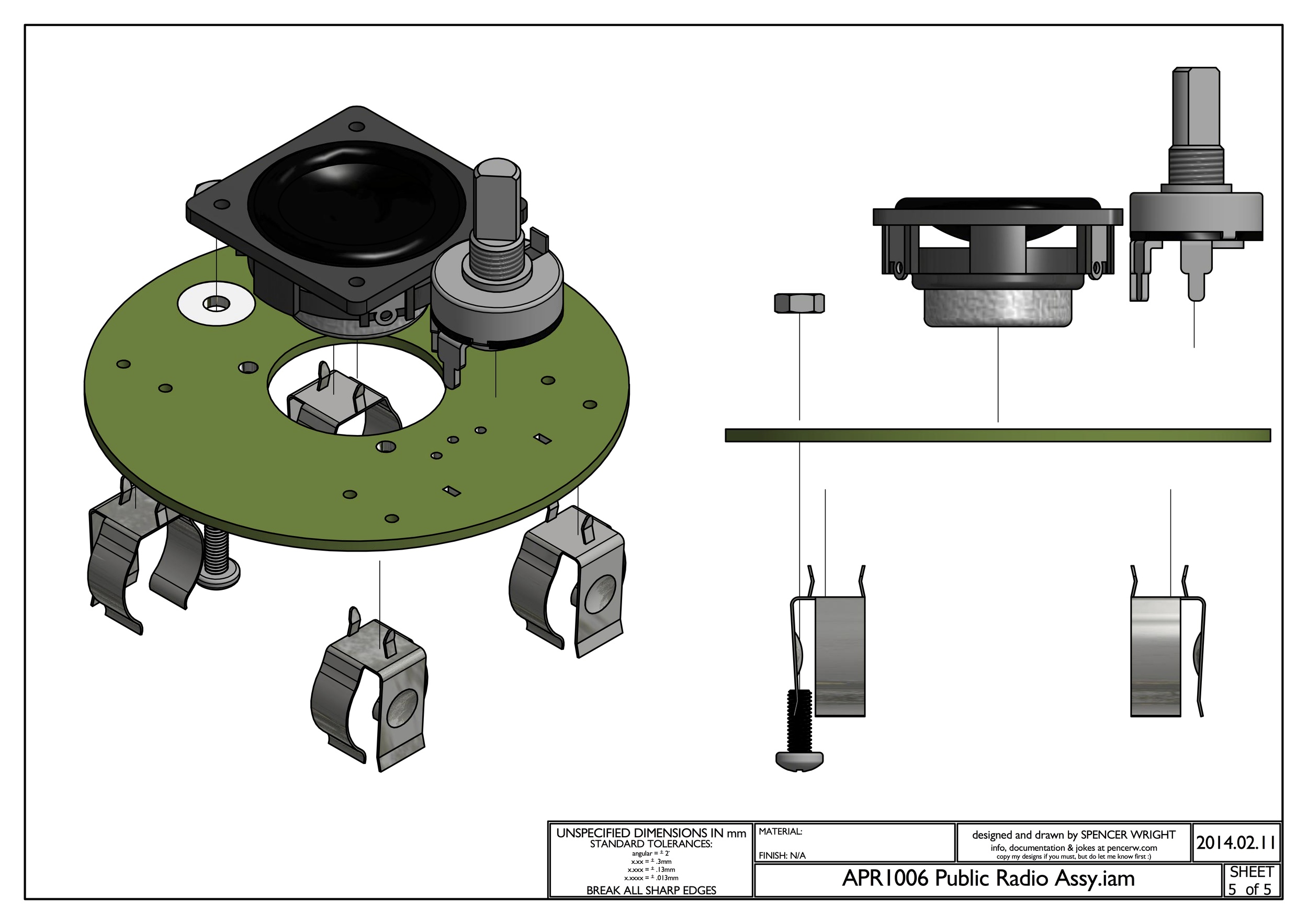

Assembly drawings

Making exploded drawings is fun. After getting the mechanical assembly pretty well dialed - and setting up my drawing template - I banged these out the other day.

We've got quotes for most of these parts in a BOM now, and should be placing sample size orders in the next few days :)

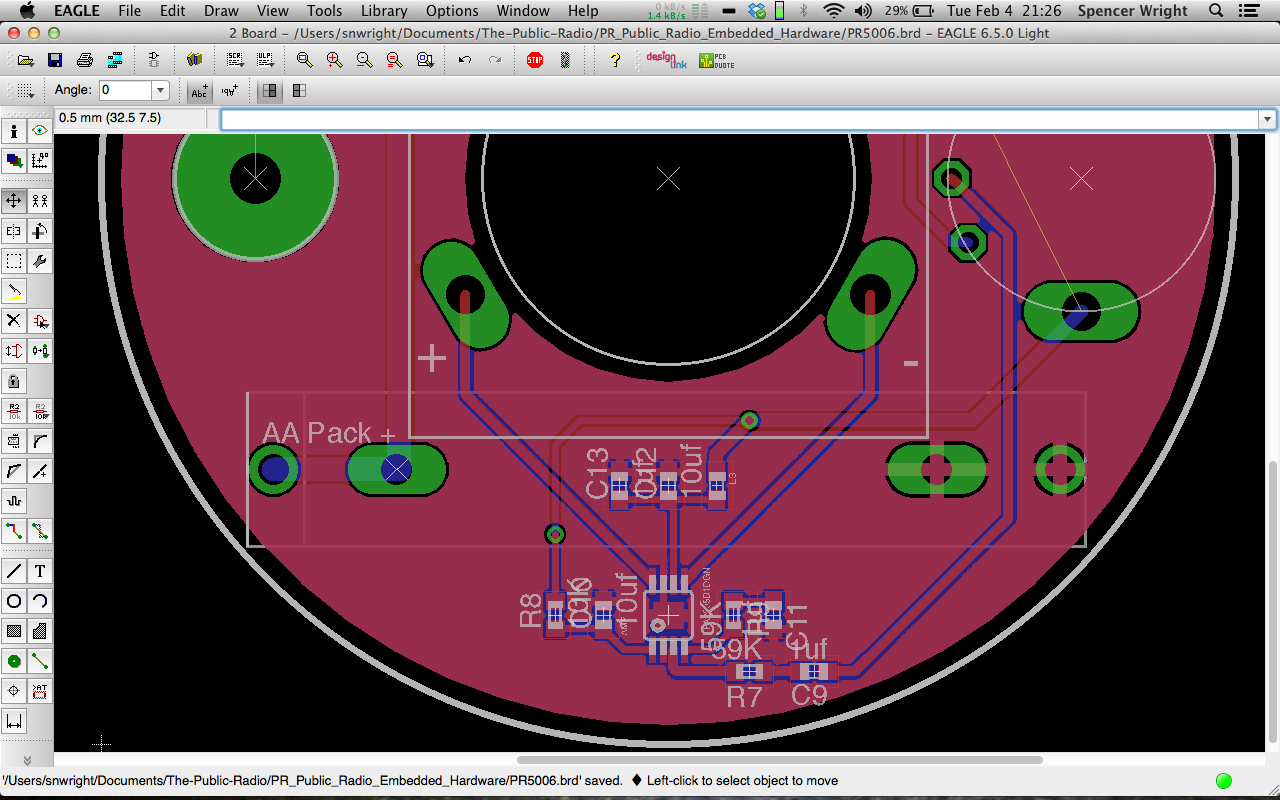

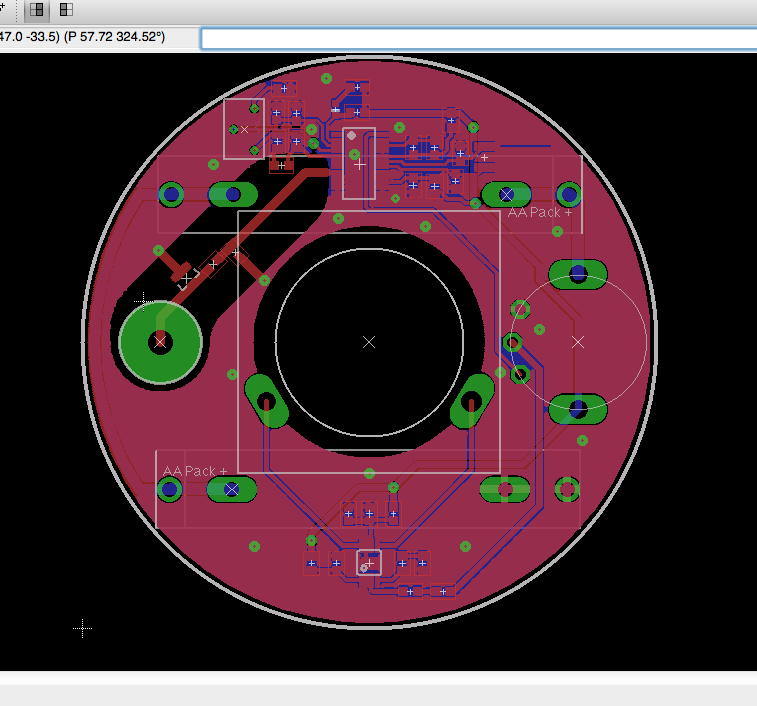

PR5006 -> PCBCart

We pulled the trigger on this today.

There are a lot of small-to-medium changes here, even from the last photos I posted.

On the top edge of the board:

- Station tune LED circuit moved to the right.

- Cap on the tune circuit changed to thru-hole.

- Trimpot package changed, moved outboard.

- Tune circuit moved up and out, to get farther from the antenna trace.

- Big thru-hole coupling capacitor on the battery, in the middle of the right side.

On the bottom edge of the board:

- Speaker traces reversed. I had originally routed negative and vise versa, but apparently that's not cool :/ Oh well.

- Power routed along the perimeter of the board - no longer needs a via to get under the speaker traces.

- Audio in was turned up and to the right for shorter traces & less interference with power.

We should have boards back in roughly two weeks. In the meantime we'll be hustling in like twenty ways so that we can be totally ready. Should be fun :)

Experience alone is a poor substitute for critical thinking.

-me.

New Standards

I've posted previously about my procurement process and elided a crucial detail: my part documentation for the past year has been pretty atrocious. Partly that's because I haven't been buying mostly 3D printed parts, which (when you buy from Shapeways et al) are documented only with STLs, but it's also because I haven't taken the time to set up my own drawing standards. Until yesterday.

This drawing is of the lid for The Public Radio. Depending on quantity it'll either be stamped or laser cut. I'd prefer stamped, but that's mostly because it'll be much less expensive at quantity - and I'd rather sell thousands of parts, not hundreds.

The details of the drawing itself are rather mundane, but the title block and drawing format involved a number of weighty decisions. A few points:

- I'm using an ISO A3 paper size. Because ISO is cool.

- I'm dimensioning in millimeters, and have default tolerances in millimeters too. This was a bit of a hurdle for me - I'm comfortable with metric dimensions but used to thinking of tolerances in thousandths of an inch - but I'm excited to be all (or mostly all) metric. Most of the tolerances here are three decimal places, which is basically the same at .13mm = .0051", is totally translatable for me.

- I'm using decimal points (instead of commas) between the ones column and the tenths column. Because Europe isn't right about everything.

- I don't have any "approved by" field. Fuck standard title blocks, right?

- "BREAK ALL SHARP EDGES." Yes.

- Note: As I'm looking at this, I'm realizing that I should probably relax a number of these tolerances. Which often happens, the more you look at a drawing.

- Revision tables. I start my drawings at "REV -", and then I increment alphabetically from there. This particular drawing was submitted to a few suppliers prior to this drawing standard, so I've incremented to "A" already... it's a little weird, but it works.

- I'm not a huge fan of "TYP" or "typical," but in some cases it makes sense.

- I'm using my part filename as a field in my title block. I considered separate boxes for part number and name, but I'm careful with filenames and this makes it easier.

- I'm using an ISO time string (but with decimal delimiters) throughout. Because ISO is cool.

- I'm a little flippant in my title block (the "info, documentation & jokes" thing), but it's better than having to list my phone number.

Changes I should probably make:

- I probably need a logo... or something. I don't know, a circle with a dot in it?

- Line weights are off.

- Do I really need to say what sheet it is? It's really only useful if you're documenting assemblies - at least with the simple parts I tend to design.

- I guess I should be marking zones of the drawing space, but I've never done so in the past and never felt like I was missing anything.

- I wish I could get rid of the file extension.

Overall I'm happy about this. Pretty fun.

Being Copied

Bunnie Huang, responding to a question about IP theft in Chinese contract manufacturing. The question is at about 22:30, here.

I'm different than a lot of people - I'm a big fan of open hardware, so before I get to that point with the factory I'll publish my schematics and everything online anyways. Feel free to copy me. Right? And the good news is that your idea was good. You were copied. None of my ideas are ever copied, so obviously they're not very good.

Found

Battery clips on GrabCAD

In case you're designing a piece of electronics and need a battery clip modeled... this MPD PCB mount one that I modeled is on GrabCAD.

Hario Driver from Shapeways

Got this yesterday:

This is a socket bit that can be chucked in a drill and used to grind coffee with a manual burr grinder. I'm toying with the idea of having some CNCd, but this 3D printed steel version will work well for testing.

I don't own the Hario grinder that it's designed for, but I'm hoping to test it this weekend at a friend's house. Expect results soon :)

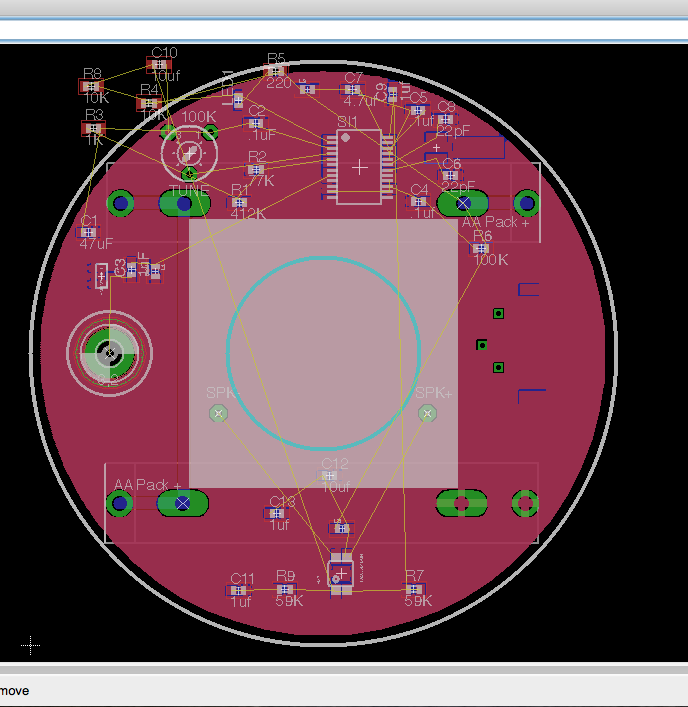

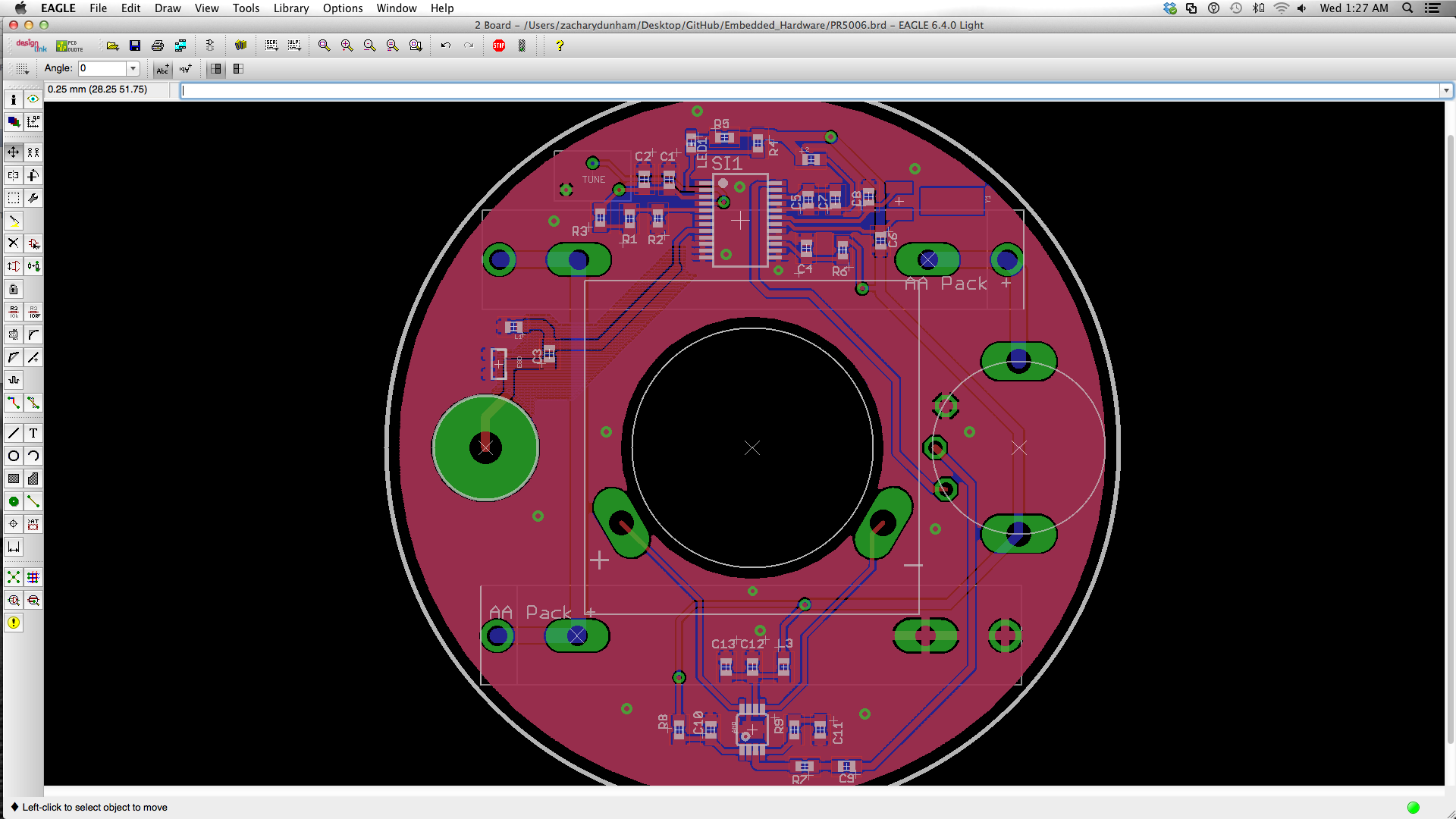

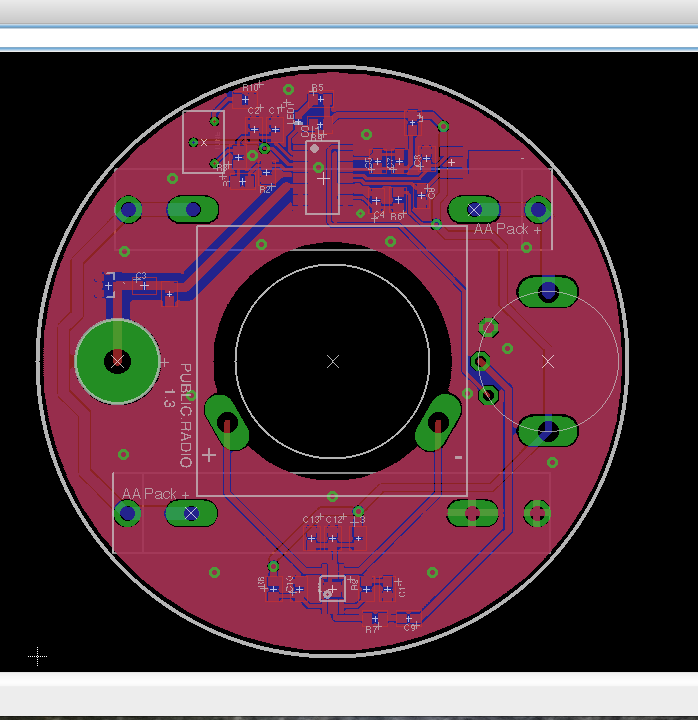

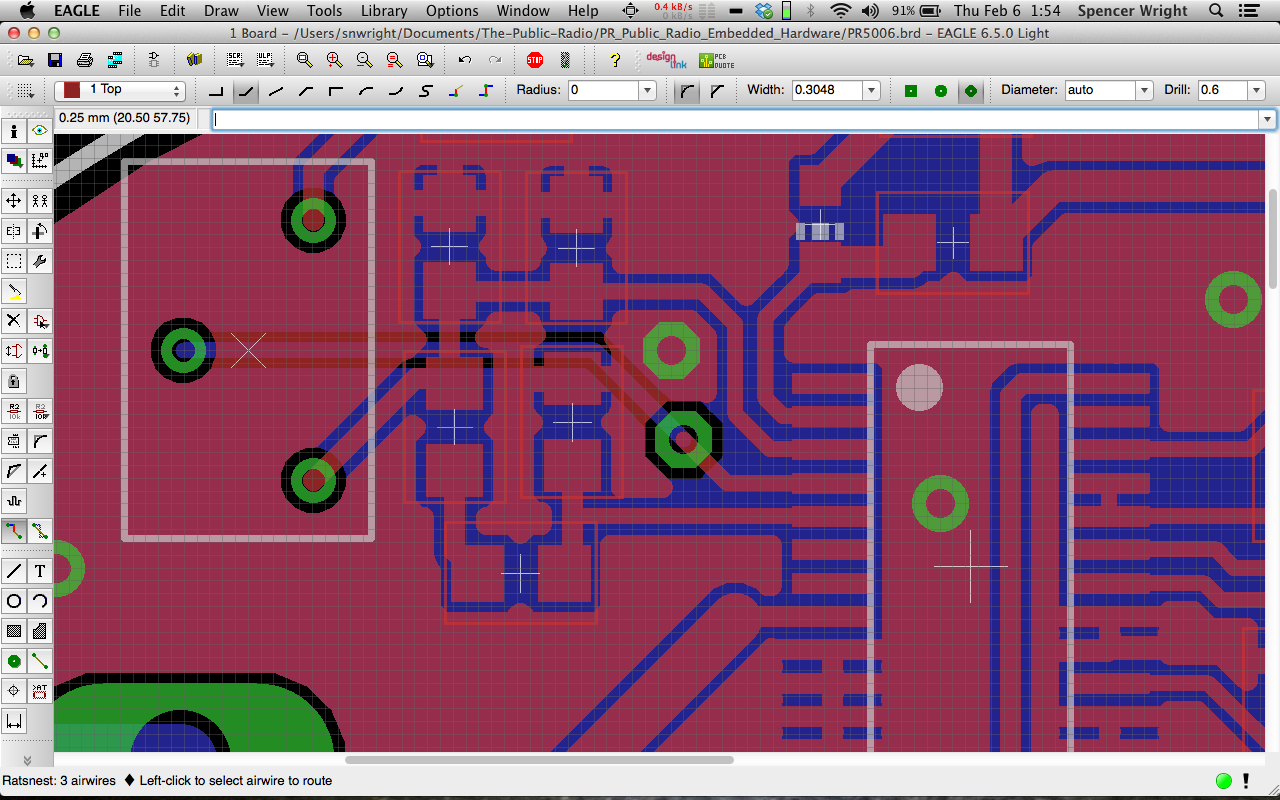

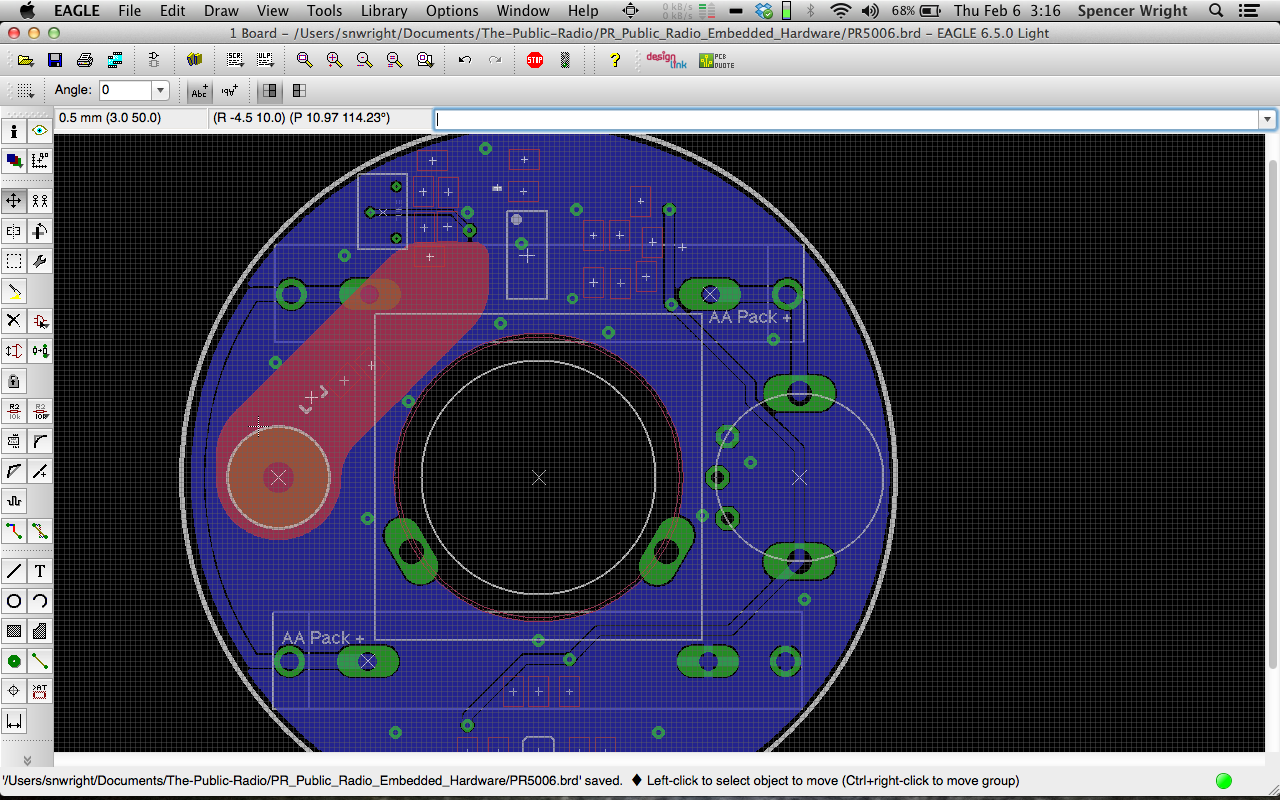

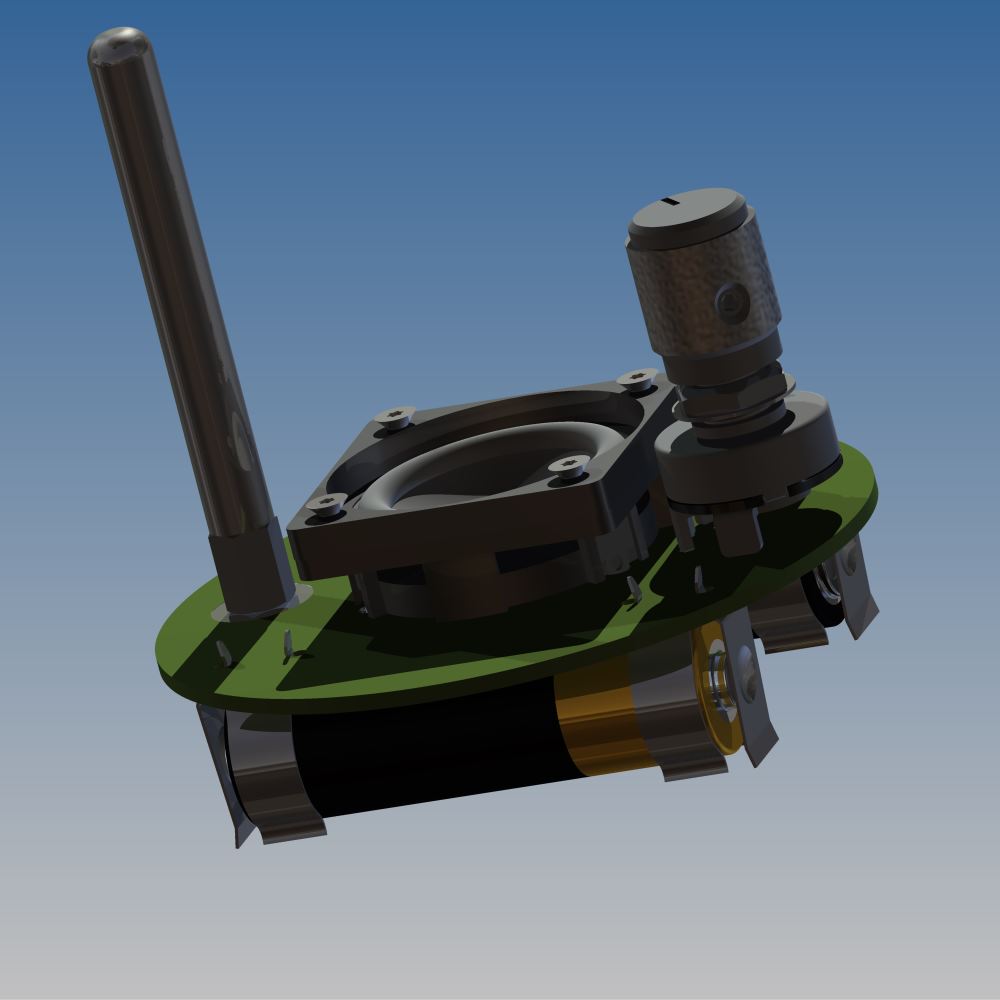

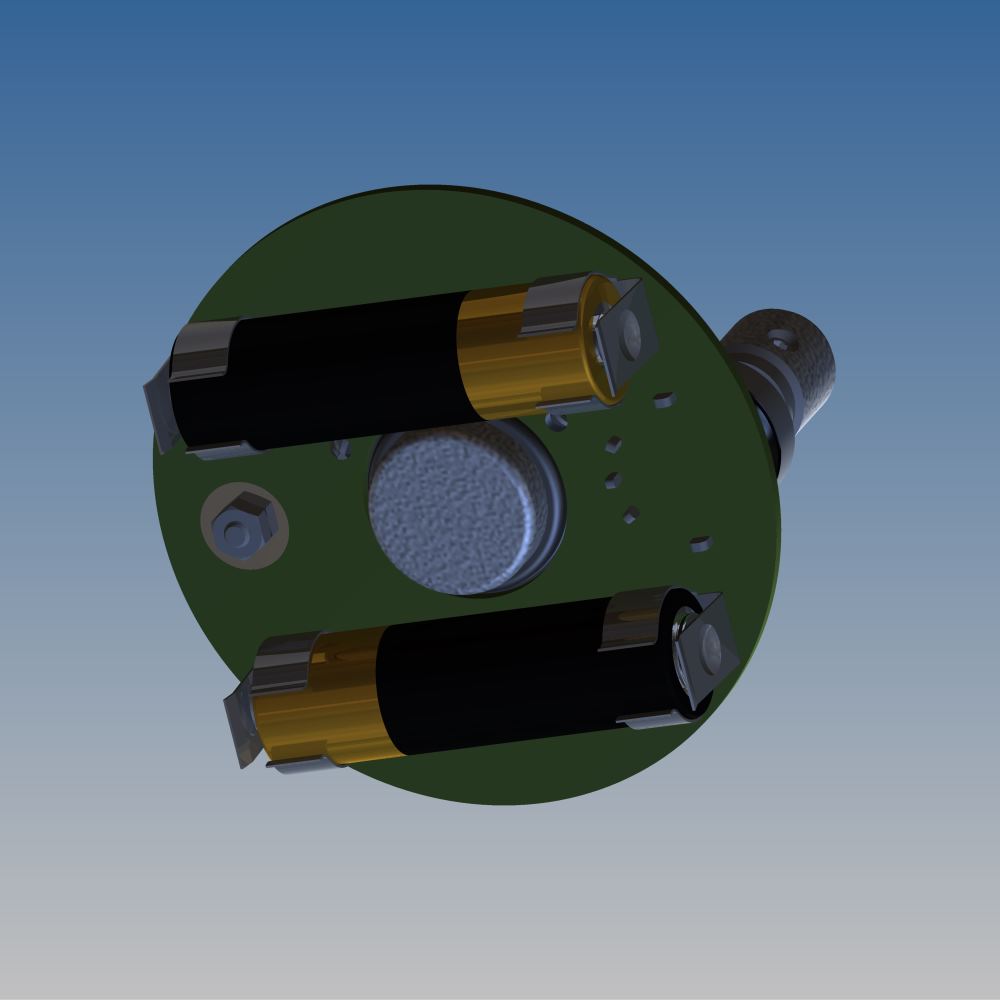

Working on The Public Radio v1.3

Screenshots from both Zach and myself - we've swapped back and forth on layout duties.

The FM IC (Si4831) is at the top of the board; to its left is the tuning circuit and trimpot. On the right edge of the board is the power & volume pot, and on the bottom is the amplifier, and on the left is the antenna connector. The middle of the board has a big cutout for the speaker body to fit through; we'll solder the speaker terminals directly to the board.

I got a little cute with the restricts near the antenna trace, and ditto on the power trace along the left edge of the board :)

Meanwhile, I spent a little time today modeling the battery connectors in Inventor:

Finding nice through-hole AA battery connectors is *tough.* I'm hopeful about these - I think they'll hold the cell firmly but allow for easy removal too. The only downside is that they're not polar in any way, so we'll need to mark the PCB clearly to show which direction the batteries need to face.

Our antenna standoff is kind of exciting too. We're running a trace to a plated hole (with a *big* pad) on the PCB, and then fastening a male-female threaded standoff to the hole with a hex nut. The antenna itself will thread into the standoff, making it easy to remove/install for shipping, transportation, etc.

We're in the process now of getting quotes for a couple of custom pieces of hardware: the antenna, the knob, the potentiometer, and the speaker gasket. We've also gotten a few quotes for the lid, which will either be stamped or laser cut stainless steel. And when PCBcart comes back from Chinese New Year, we'll order a batch of new boards to get into the hands of our beta testers.

This is an exciting time in the project. Things are coming together quickly :)

Shapes

Scott DeFelice, CEO of Oxford Performance Materials, said something in conversation yesterday that I found really prescient. I'm paraphrasing this a bit from my notes, but the feeling is there:

There is a business selling shapes. It's not a new business. Shapeways and MakerBot are doing interesting things with the business model, but it's the same business.

The business of selling *useful* shapes is totally new.

What Scott's saying here rings true to me: When designers are able to create shapes that are functional in and of themselves, the nature of the product - and its value to the end user - changes dramatically.

If I'm selling shapes, I want to be selling useful ones.