The last few days have been a bit of a whirlwind.

First, we visited Todd to discuss some circuit layout concerns. On the way over we nabbed a cheap radio at RadioShack, and took it apart with Todd..

What we found was really interesting. The device uses a different chip than we had been prototyping with, and as a result their circuit is *much* simpler. Our chip (Silicon Labs' Si4703) requires digital tuning, which we were accomplishing with a microcontroller. But RadioShack was using the Si4822, which is mechanically tuned. The result is drastic from a circuit standpoint - they no longer need a voltage regulator, or a microcontroller, or a bunch of additional passive components on the board. They're also in a better position re: noise on the board: an MCU (and a voltage regulator too) will produce a bunch of noise that might get on the antenna, affecting reception. RadioShack doesn't need to worry about this at all.

Over the past few weeks, we've been looking for just a breakthrough like this - a way of rethinking the problems we were dealing with. Our issue was that we were stuck conceiving this as an Arduino-descended product, which it doesn't need to be.

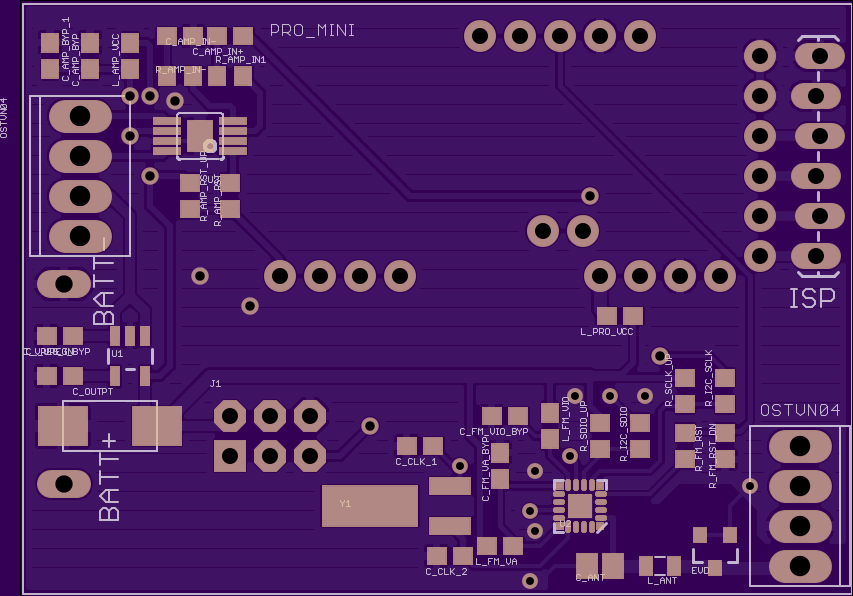

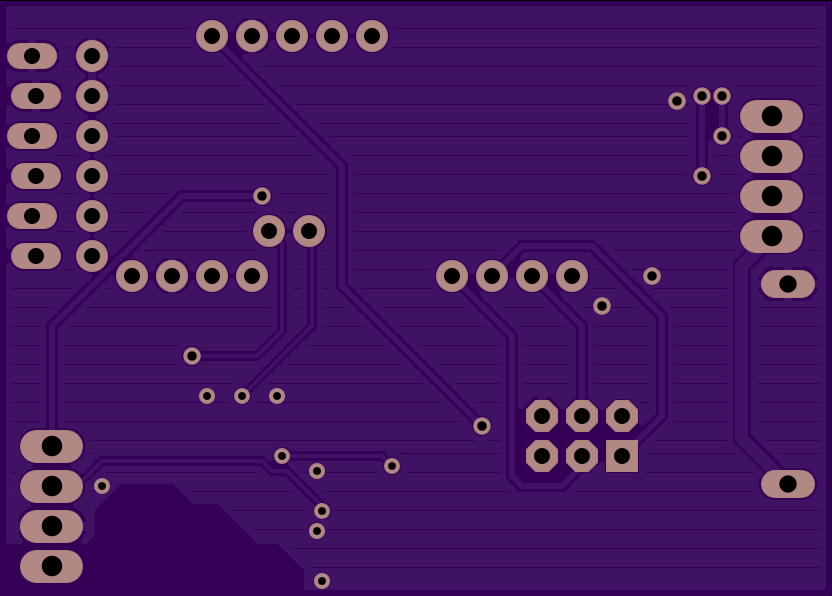

We also made a bit of progress reengineering the hardware layout of the board. Our new design (this is just the board layout, not the circuit schematic) will be significantly easier to assemble, program & service.

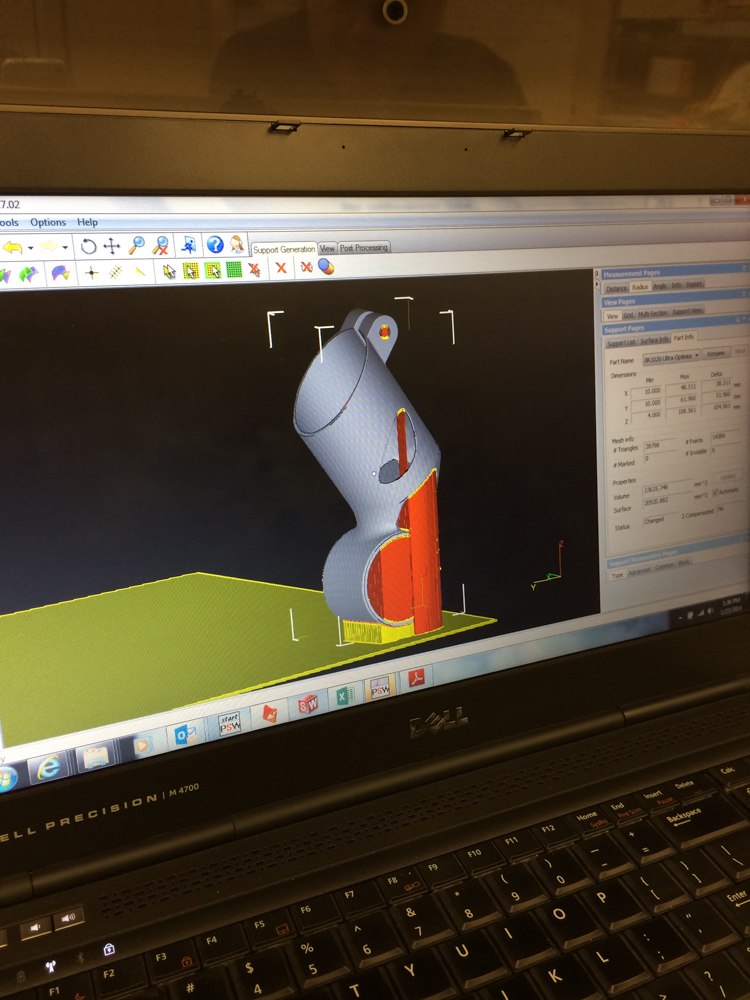

We're also pretty sure we can shorten the antenna *significantly.* The mockup here shows a custom solid stainless steel antenna, 50mm long. I rather like it, and it's designed such that a longer telescopic antenna can be swapped in easily.

Our PCB will now be circular, and we're soldering the potentiometer and speaker directly to the board. There will be a bunch of SMT stuff on the top (same side as the speaker & pot) and a battery back and trimpot (not shown) on the bottom.

I *really* like where this is headed. More updates soon.