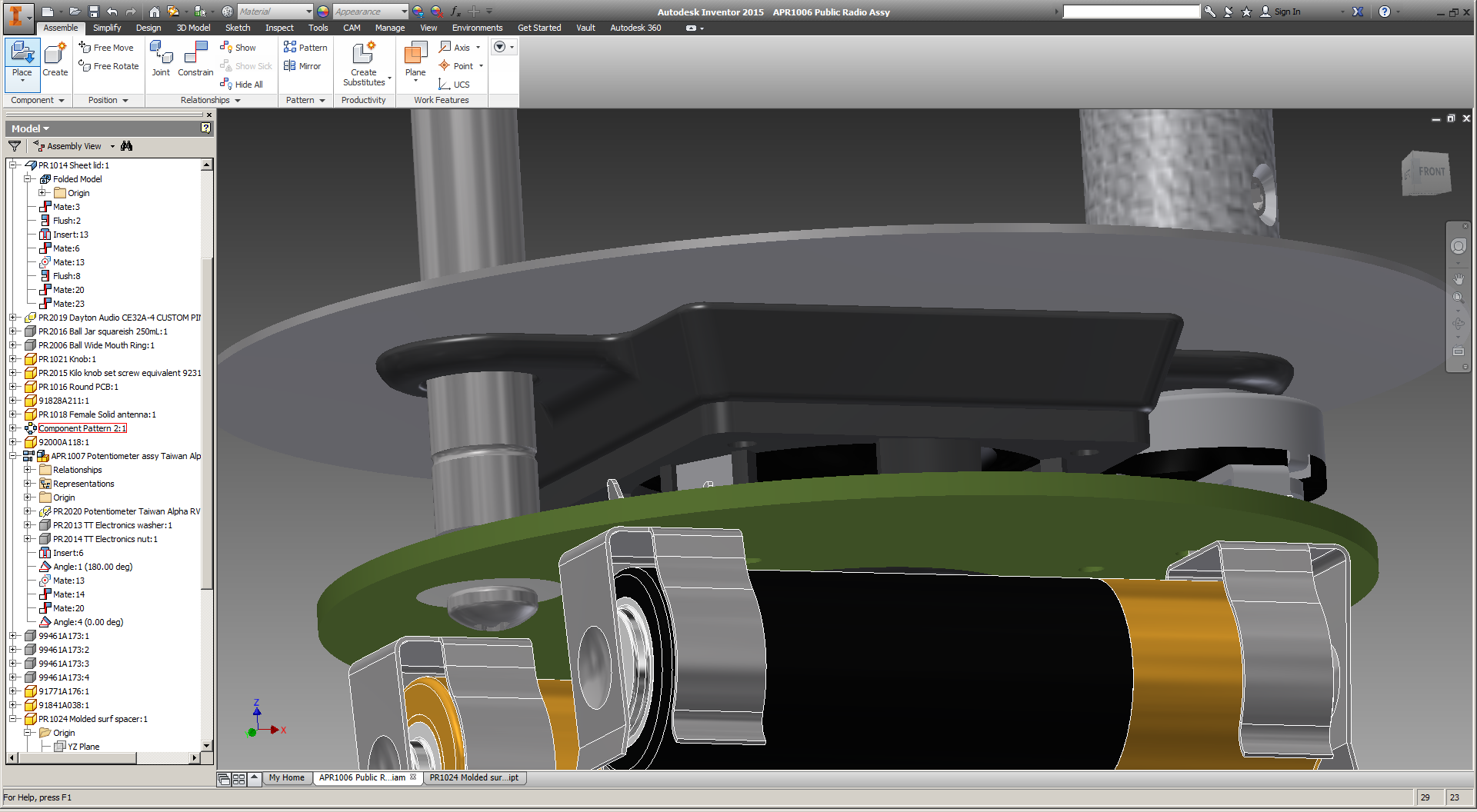

Location: Amazon’s Middletown, Delaware fulfillment center

560 Merrimac Ave, Middletown DE.

Present:

- Spencer Wright

- Rob Snowden

- Dan Suo

- Jason Spinell

Arrived at 0945

Tour began at 1000

Tour completed at ~1115, and was quick almost to the point of being rushed.

Tour guide was named Evan

Notes taken retrospectively by everyone above.

This facility is 1.2 million square feet. The parking lot had somewhere around 2-3000 parking spots, and was mostly full. There was a sign saying “First Day Starts Here” in the front, and a number of what looked like brand new employees doing orientations. This is a “sort” facility, as opposed to a “non-sort” facility. The difference is that all of the items in a sort facility fit in a yellow bin (about 14”x14”x24”).

There are two sides to the facility: Inbound and Outbound. Inbound receives stuff from suppliers and also from other Amazon facilities (“transfer”). They’re doing a lot of transfer right now in prep for “peak season” (i.e. the holidays). Outbound ships orders to customers, and also presumably to other distribution facilities.

Most of the time, employees work 4x10hr days. There are two daily shifts, leaving the facility closed for a few hours a day. There are about 3000 people in normal employment at the facility. During peak season, they ramp up to 6x10hr days. I believe they also shift the schedules a bit, such that the facility is humming 24x7. They also increase their staff, up to about 6000 people.

At inbound, pallets come in and the bill of lading is checked. Then the boxes are loaded onto a conveyor. One team of associates *just* open the boxes. Then another team picks a box out, empties the items out, and checks quantities. Then (I think) they add an ASIN if the item doesn’t have its own UPC.

They use random storage at the facility. There are cubbies everywhere, and each has a bar code. Inside each cubby is up to 6 unique SKUs. If a SKU is in one cubby, it CANNOT be in any adjacent cubby.

There are about 300 Pickers at this facility. They are managed by two managers. Pickers find the cubby they’re assigned to look for, scan its barcode, and then find the item within that cubby that they’re supposed to pick. They scan the item’s barcode, and drop the item into their bin. If a picker finds a broken item, they put it in a red bin at the end of the aisle, where QC can find and fix/dispose of it. If a picker finds an item that’s not in its proper cubby (e.g. on the ground), they put it in a blue “amnesty” bin, where QC can pick it up and return it to its proper location.

Once they get all the items on their current list (which does *not* correspond to a customer order), they put the bin on a conveyor, and it goes up to sort.

At sort, an associate has a bin (from the pickers) and an 8020 rack on casters that has a few dozen cubbies on it. They pick an item at random out of the bin, scan it, and then a monitor tells them which cubby to put it in. Here, the cubbies *do* correspond to customer orders. Once the rack’s cubbies are all full, the rack gets wheeled over to the pack stations. Each cubby has a packing list in it.

There are about 100 Packers at this facility. They have one manager, and two or three assistant manager types. The packers take a packing list and its items out of the rack. They scan the packing list and it tells them which box to use. Different packers have boxes of different sizes; so one packer might have small/medium boxes, and another might have larger boxes.

They pack all the items into the box and fold it up, putting the packing list inside. They have a machine that wets water-activated shipping tape and cuts it to length automatically. All they have to do is press a green button and the machine already knows what kind of box they’re using and spits out a piece of tape that’s just the right length.

Each packer has a set of Andon lights above their station, which indicate their ability to perform their work. During normal operation, the Andon light is green. If the associate is running low on supplies, they turn it to blue; if they have a serious blockage or shortage problem, they turn it red. Andons are constantly monitored by support staff, who will come to assist if a packing associate is unable to do their job.

They seal the box up. Then they take a barcode sticker off of a reel, scan it, and put it on the box. At this point that barcode is assigned uniquely to the customer’s order. The box goes on a conveyor. It is automatically scanned, and has a shipping label printed and slapped onto it by a machine (this was *cool*). A spot on the conveyor weighs the package, and if the weight is off then it goes into QC.

The packages are sorted roughly by size and go onto a long oval conveyor. At one point on the conveyor, a 360* scanner checks the barcode and figures out which truck (by shipping zone) the package needs to go on. Then, as it’s going around the conveyor, little pushers kick the package off the conveyor at the right chute, and it’s sent down to the truck to be loaded.

Humans load the trucks, creating big walls layer by layer. They try not to stack the same box size very high, because it’ll become unstable unless the stack is interlocked at a lot of points.

Other notes:

- The whole place was rather spartan.

- Our tour guide used an iPhone, but claimed he’d use a Fire if he wasn’t locked into his carrier.

- Our tour guide is normally an Ops guy; tours are *not* his full time job.

- Their “___ Days since last workplace injury” sign was *not* filled out.

- They had Grainger vending machines with “free” PPE supplies inside - but they track employees use of those supplies.

- They were very excited about FBA (fulfillment by Amazon) and their MOS (make on site i.e. print books on site) programs. FBA packages get plain brown packing tape (as opposed to the Amazon branded tape), but otherwise the whole process seemed to be very similar to Amazon owned items.

- Our tour guide was very enthusiastic about a few TPS things. He mentioned Kaizen (literally “good change”), which to Amazon is a program where people from throughout the organization get together to propose and implement significant improvements in their processes. The Andon lights in the packaging department are also a derivative of a Toyota production feature.

- Amazon has a number of “etiquette” policies, which refer to the “nice” way of doing things. For example, heavy items shouldn’t be stored on shelves above head height). It was unclear whether these guidelines were substantially different from rules, but with friendly names.

- The whole place was highly automated. The box & tape length selection systems were really interesting, and have the effect of making the packers into just highly adaptable robots.

- When the tour was over, Evan (with some enthusiasm) gave us all Amazon branded cigarette lighter USB chargers.