The path to The Public Radio’s Kickstarter campaign, and how we see the challenges ahead.

Background

About eighteen months ago, Zach came to me with an idea: an FM radio that only tunes to one station. We had recently completed MITx’s circuits & electronics course, and were looking for a project to apply ourselves to. This one was perfect: it was small, simple, and catchy. The Public Radio was born.

An early prototype.

Over the following year, we chipped away at the project on nights and weekends. It’s hard to say how much time was spent, but 400 hours each is conservative. We tracked expenses casually, but have records totaling about $5000, most of which went towards electronic parts, printed circuit boards, and prototype mechanical components. All in all, we invested the equivalent of tens of thousands of dollars on the project, and got a *ton* of value — in experience, mostly — out as a result. Regardless of where the project went, we both strongly felt that the trade was worth it.

Preproduction

In February, we launched a beta version of The Public Radio on Grand St. It was a great way for us to get a few units into the wild, and forced us to come up with scrappy solutions to the problems we’d face ahead. A lot of them weren’t permanent, but they were good enough — and getting support from random strangers felt great.

But building the radios was painstaking. We did all of the assembly in my kitchen in Bed Stuy, spending long nights hunkered over soldering irons to ship on time. It was tough, especially as — even ignoring our labor — we were barely covering our own costs.

COGS

Calculating our costs of goods sold is a bit tricky; different parts scale on totally different curves. A few notes:

- Most electronic components get cheaper as you buy more, but they don’t get really affordable until they buy them in quantities of 2500 or more. Our FM IC (the core of The Public Radio and one of our most expensive components) costs $12.76 if you buy one; $11.88 each if you buy a hundred; $3.51 each if you buy a thousand; or $1.85 each if you buy a full reel of 2500. Most off-the-shelf electronic components follow a similar pattern.

Our first shipment of potentiometers.

- …But, not always. Our volume potentiometer is a non-stock part; we needed to order them in quantities of 1000 direct from Taiwan. They cost $.45 apiece, plus a $30 banking fee (international wire transfers are a PITA) and $155 in shipping. Rollup cost: $.63 each. This will go down only *slightly* with quantity: if we purchase in quantities of 10,000, we save $.01 per piece.

- Our jars don’t scale particularly well. They’re sold in sets of four, which you can buy retail for $4.99. To buy wholesale you need a $100 minimum order, at which point the price per 4 units is $3.28, but the shipping costs (these things are bulky and fragile) put the rollup cost per unit at $1.78. If you get up to a $500 order, they apply a flat $125 shipping fee, plus $30 to ship it to our (residential) address; that all rolls up to about $1.07 apiece. If you get to $2500, though, the shipping is free, putting the unit price at $.82 — assuming you’re shipping to an address with a loading dock. The net effect: We want to be buying jars in minimum quantities of 3,049 units.

- Some parts just don’t come in quantities of one. Our first few radios used antennas we found on eBay, which worked… okay. We did a bunch of research, and found that antennas just *aren’t* made in the US. In the end, we ordered ours custom from a company in Shenzhen called Sinowares, which required a minimum order quantity of 500, at which point they cost $1.20 apiece plus $100 in shipping. These don’t scale particularly well either; at an order of 10,000, they only drop to $1.15 apiece.

- Producing our lid in quantity will require tooling, which brings the effective unit cost up for our initial order. Our first radios had lids that were laser cut (no tooling required), at a whopping cost of $7 apiece plus shipping — by far our most expensive line item. For production, I expect to spend somewhere between $500 and $2000 in tooling. If we get them made in the US, the unit cost (not including tooling) will be roughly $1.20 for quantities of 500 and $.95 for 2500. We don’t have a clear line on Chinese production, but I expect the pricing to be lower, though somewhat less scaleable.

The end result: In small quantities (<100) The Public Radio costs between $30 and $35, plus shipping and *not* including labor. Our price on Grand St. was $40 plus shipping, which we usually lost money on.

Inspecting the FM IC.

Labor is difficult to calculate precisely. Assembling surface mount components is time consuming; we spend about an hour per radio on that alone. Then there’s QC, mechanical assembly and tuning, all of which takes an additional 30–60 minutes. Add the fact that we were shipping orders one by one, and you’ve easily got two hours per radio in labor.

All in all, our Grand St launch did *not* make us money — but it did give us a great chance to cover some of our costs as we moved towards bigger volumes. For that, it was incredibly valuable; I’d do it again in a heartbeat.

The Rub

Building electronic products by hand is hard. And expensive. So, scale it a bit.

Our ultimate goal is, and has been, to sell The Public Radio at wholesale prices direct to radio stations — who would use them as a tote bag replacement during fund drives. Remember that even if we scale our purchasing and assembly, these things need to be tuned to the customer’s station before they’re shipped. If we can tune them in batches — say, a hundred or a thousand all to the same station — then we save ourselves a *lot* of work.

Kickstarter is, admittedly, not specifically tailored to establishing a wholesale business. There are a lot of logistical challenges that we’ll face selling to individuals, and it’s unclear whether we can deal with them in a way that’s sustainable long-term. But Kickstarter allows us to get access to a big network of people, and gives an opportunity to reach out to station managers and say “we’re doing this thing; let’s talk about it.”

Preparing

Figuring out the details of the campaign were *hard.* Aside from issues in producing a video (I can only blame this on the poor on-screen appearance of yours truly; both Zach and Colin (who was super gracious about helping us out) did a great job), the real difficulty was in setting the unit price (i.e.reward level) and funding goal.

We’re offering a handful of non-radio rewards in the campaign, but the bread and butter will be the “radio monogamists” level, which consists of an assembled and tuned Public Radio, including jar. Drawing from what we learned about buying habits on Grand St., we decided that $40 is a reasonable street price; we then averaged our shipping costs across the country and added $8 to cover those. As a result, the shipped price for our mainstay reward will be $48.

To be clear, the $40 baseline here is simply an estimate of what the market will bear. When we launched on Grand St, we started at $60, but after a week or so of no sales we dropped it to $40. That was the extent of our research, essentially — we couldn’t imagine it on a shelf for much more than $40, so $40 it is.

The funding goal was trickier. In the year+ that we’ve been working on this, we’ve spent $5–10k in cash — not to mention *months* of our weekends and after-work hours — developing it. It’s been a huge effort, and releasing it to the public will be even harder. But we’ll never get that time back, and anyway it has already paid for itself (in intangible rewards) many times over.

So, you just take that out of the equation — and expect to take many, many hours of future work out of the equation too.

We ended up setting a funding goal of $25,000, which corresponds to 500 units sold at $48, rounded up a thousand bucks for good luck. In the end, the deciding argument was this: while our cost structure at $25k probably wouldn’t make us money, the experience — and pulling it off — would be totally worth it.

Fulfillment paths

The exact quantities at which our production modes shift are still up in the air, but there are a few ways we *think* this can go.

We barely fund, selling about 500 radios.

Obviously this didn’t happen, but nonetheless: At quantities of 500, we should be able to get our COGS down to about $30 (but not much lower). As a result, our income above COGS is about $10 per radio, though much of that will end up going towards payment processing & Kickstarter’s fee. Not counting costs incurred for reengineering (which would probably be minor, as the marginal benefits wouldn’t add up to much), supplier vetting, and our own labor, we’d expect net income for the whole project to be about $2500. In short, we’d lose money on the deal — but gain invaluable experience as a result.

In this scenario, we’re probably using a local vendor for our PCB assembly, and doing a lot of the mechanical assembly ourselves. There would be a *lot* of long nights ahead, and many of them would be spent doing assembly and distribution ourselves.

We overfund, but not enough to buy reel quantities or amortize our tooling.

This is roughly where we are now — somewhere in the 1500 unit range — and it’s a *very* uncertain place to be. At 1500 units and a $28 COGS (we’d save a bit of money from the increased scale alone), our net income off of a $72,000 campaign will be in the range of $6500. If we reinvest that into engineering and reduce the COGS to $21 (still speculative at this point, but not without reason), we might be able to increase our net income to about $10,000. Do we take that risk? Either way, we’ll probably be incentivized to buy a number of our components in larger quantities; how do we deal with the excess inventory? Do we push The Public Radio to become a sustained business, even if we don’t currently have the demand to support it?

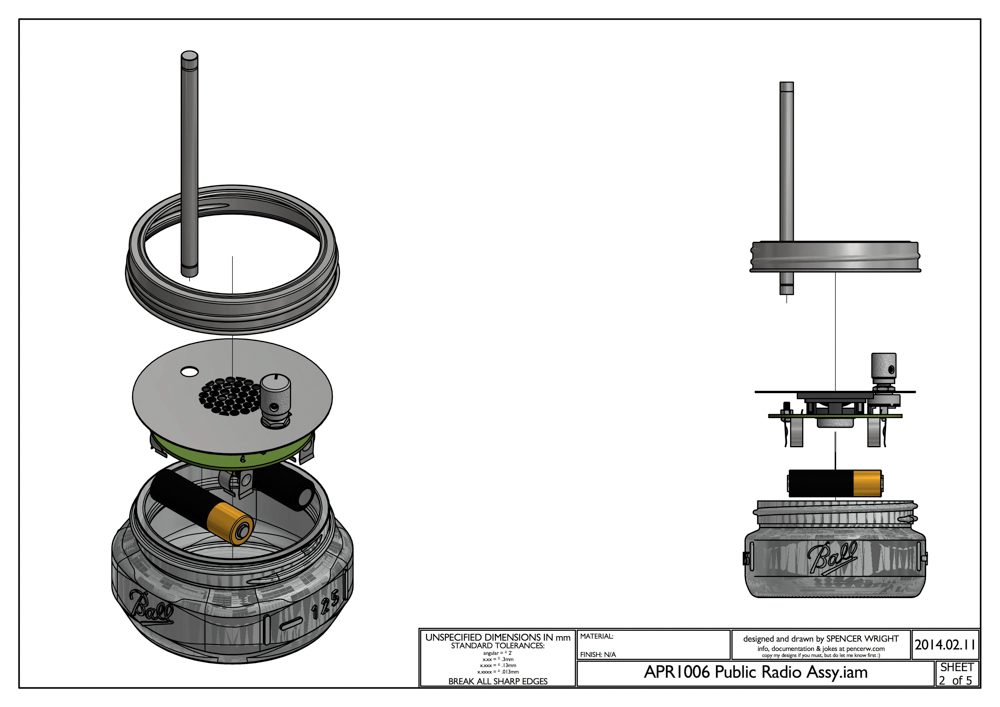

The Public Radio's final assembly step.

In this scenario, we’re probably outsourcing our PCB assembly to a larger shop and setting up a temporary space in NYC to do mechanical assembly, packaging, and distribution. Our roles become more managerial; we’ll get help to do a lot of the manual work. The career implications here loom large: this quantity will require a lot of energy, but might not provide full time employment for either of us.

We overfund by an order of magnitude or more.

Once we get to the 5,000–10,000 unit range, the game changes. At this point we’re outsourcing most of our operation, hiring a third party logistics company, and cutting out every fraction of a cent from our BOM. Production is probably done overseas, and the entire product is reengineered for scalability.

It’s conceivable, in this scenario, that we end up drawing salaries for our work. Regardless, we’re talking about *manufacturing* here — not just a project. I‘m not sure exactly what this would entail, but it’s safe to say that we probably wouldn’t be shipping radios out of my apartment.

How we’re looking at it now

There were a few days, early in our campaign, when we weren’t sure if we’d make $25k. As I write this, we’re at $70k with two weeks left, and we’ve had interest from both radio stations and retailers for large-quantity orders.

In short, we’re moving towards something resembling a sustainable business — which, to be honest, is a bit surprising. Many are the times that we’ve told ourselves that what we were working on was good in and of itself; to have it get bigger — and offer opportunities to think about a larger scale of commerce — is exciting and weird.

Regardless, the path forward is fascinating. We’ve stumbled upon a niche product that people seem to really want, and now we have the chance — and the priveledge — to fulfill that desire. Whatever the future holds, we’re ready for it — and look forward to sharing what we learn.